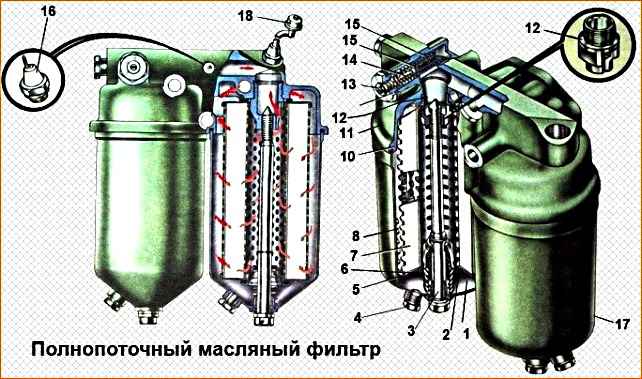

The full-flow oil filter (Fig. 1) is secured with three bolts to the right side of the lower part of the crankcase through a gasket and consists of a housing 11, caps 17 and two filter elements

Filter elements consist of outer and inner perforated cylinders with covers at the ends.

A paper tape 7 is placed in the annular space between the cylinders, folded like an accordion to increase the filtering surface.

Two such replaceable elements are mounted on rods 3, with which the caps are pulled through the sealing rings 10 to the body 11.

Each element is centered by bushing 12 and is also pressed to the body by spring 6 through cup 5 and o-ring 2.

Full flow oil filter: 1 - cover; 2, 10 - sealing rings; 3 - rod; 4 - drain plug; 5 - bowl, 6 - spring; 7 - filter element; 8, 9 - perforated cylinders; 11 - body; 12 - bushing; 13 - screw; 14 - moving contact; 15 - bypass valve; 16 - alarm sensor for emergency pressure reduction; 17 - cap; 18 - oil pressure sensor

The oil pumped by the pump enters both caps simultaneously and passes under pressure through the pores of the paper tape into the space between the filter element and the rod.

From here, the purified oil enters the oil line through a channel in the housing.

Over time, the pores of the filter elements become clogged and the oil begins to flow into the main line unpurified through bypass valve 15.

When the valve opens, it presses the movable contact 14 against the screw 13 of the indicator and this turns on the lamp on the instrument panel in the cockpit.

Usually the lamp lights up immediately after the engine starts. If it continues to burn steadily even after warming up, the filter elements must be replaced.

Emergency pressure sensor 16 turns on the warning light on the pressure gauge in the cabin when the oil pressure in the line drops below 70 kPa.

The oil pressure in the system is controlled by an electric pressure gauge, which operates from a sensor connected by a tube through threaded hole A in the housing to the main line.

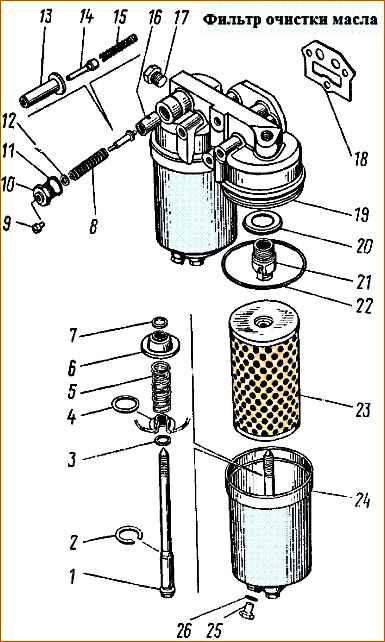

Replacing filter elements

1 - rod; 2 - retaining ring; 3, 7 - washers; 4 - sealing ring; 5 - cap spring; 6 - sealing cup; 8 - bypass valve spring: 9 - alarm screw; 10 - bypass valve plug; 11,18, 20, 26 - gaskets; 12 - adjusting washer; 13 - signaling device body; 14 - movable contact of the signaling device; 15 - alarm contact spring; 16 - bypass valve; 17 - plug; 19 - filter housing; 21 - body bushing; 22 - sealing ring; 23 - filter element; 24 - cap; 25 - drain plug

To change the filter elements of a full-flow oil filter:

- - unscrew the drain plugs on the caps and drain the oil from the filter into a supported container;

- - unscrew the bolt securing the filter cap and remove the cap together with the element;

- - remove the filter element from the cap;

- - in the order indicated, remove the second cap and filter element;

- - wash the filter caps with diesel fuel;

- - replace the filter elements and assemble the filter; check for oil leaks in the filter connections with the engine running.

If there is leakage, tighten the bolts securing the caps. If a leak in the cap seal cannot be eliminated by tightening the bolts, replace the rubber sealing gaskets;

- - after replacing the filter elements, bring the oil level to normal