The fine fuel filter is designed to remove from it the smallest mechanical particles that were not retained in the coarse filter;

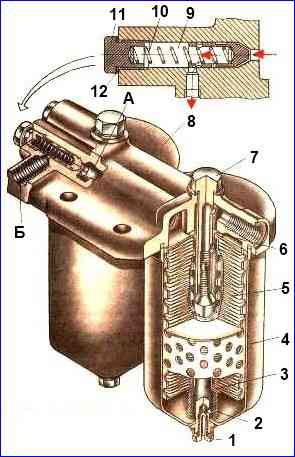

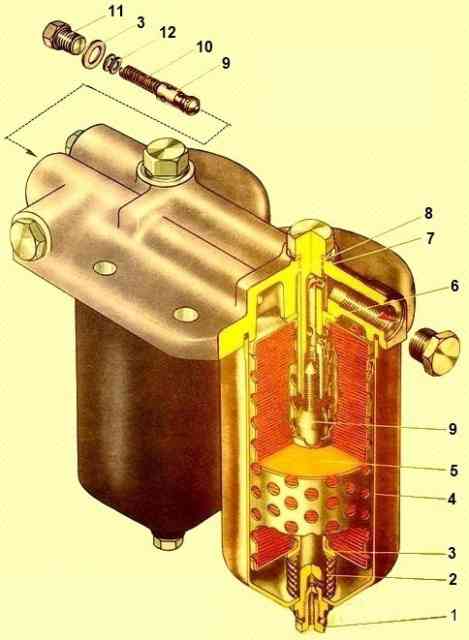

- consists of a housing 8, two caps 4 with two paper filter elements 5 installed in the caps and sealed with rubber gaskets at the top and bottom

Under the pressure created by the booster pump, fuel enters the cavities between the walls of the caps and the filter elements.

Passing through the pores of the filter curtain, the fuel is cleaned and collected around the central rod.

From here, the purified fuel leaves the filter through the channels in the bolt rod 7 and the housing to the high pressure fuel pump (HPF).

Since the fine filter is installed above all other devices of the power system, air that has penetrated into the system accumulates in it, which, together with part of the fuel, is discharged through valve-nozzle 9 into the fuel tank.

The jet valve begins to move and opens the passage for air and fuel vapor through channel “B” into the fuel drain line at a pressure in cavity “A” equal to 25-45 kPa.

When starting a cold engine in winter, the pores of the filter curtain may become clogged with ice crystals and paraffin flakes, which can form in diesel fuel at low temperatures.

In this case, the pressure at the inlet to the filter increases and when it reaches 200-240 kPa, fuel is bypassed through the nozzle valve from cavity “A” to channel “B” and then through the drain fuel line into the tank.

In this way, the jet valve protects the filter elements from destruction.

The valve opening pressure is adjusted by selecting washers 12 inside plug 11.

If the filter elements are highly clogged, fuel also drains freely into the tank.

At the same time, the fuel supply to the high-pressure pump deteriorates, as a result, engine power decreases or its operation stops.

To change filter elements you must:

- - unscrew the drain plugs two or three turns and drain the fuel from the filter into a container, then screw in the plugs;

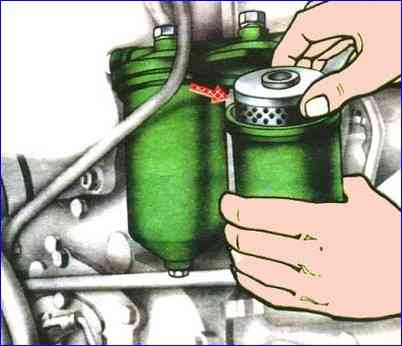

- - unscrew the bolts securing the filter caps, remove the caps and remove the dirty filter elements;

- - wash the caps with diesel fuel;

- - install a new filter element with sealing gaskets in each cap;

- - install caps with elements and tighten bolts;

- - start the engine and check the filter for leaks

Fuel leakage should be eliminated by tightening the cap bolts