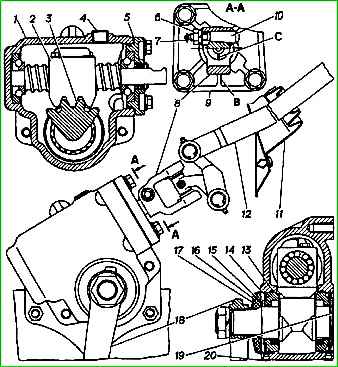

Adjust the bearings when axial or radial play appears in the bearings of screw 2. To ensure the presence of these clearances, you must:

- turn the steering wheel 2.½ turns from the straight-line position in any direction;

- swing the steering gear screw by the fixed fork by hand; if the screw has axial or radial movement (play of the fork relative to the steering mechanism cover), then the screw bearings must be adjusted.

Adjustment is carried out in the following sequence:

- - disconnect bipod 18 and steering wheel shaft fork 12;

- - unscrew the bolts securing the steering mechanism to the bracket and remove the steering mechanism from the car;

- - drain the oil through the hole closed by plug 4;

- - remove two plugs 20 on the crankcase;

- - remove two covers 17 and 19 and sponge seal 16 of the sector shaft;

- - remove retaining ring 14;

- - straighten the grooves on the bearings of the sector shaft with a bead and remove them with a puller, eliminating impacts and distortions on the bearing;

- - remove shaft sector 3;

- - unscrew the bolts securing the upper crankcase cover, remove the cover and remove one of the adjusting shims 5;

- - install the crankcase cover in place and check the torque of the screw in the bearings.

The moment should be 0.4-0.8 Nm (4.0-8.0 kgf/cm). In this case, no play of the screw should be felt;

- install sector shaft 3 and bearings, lubricating the seating surfaces and sealing rings with steering oil.

When installed, the bearings should be directed with eccentricity downwards (the sector shaft is as far away from the ball nut as possible).

Distortions during assembly are not allowed.

You can also see the article on this topic - “Adjusting the steering of the GAZ-2705”

Seizing of bearings on the sector shaft or crankcase indicates misalignment or incorrect orientation of the bearing eccentricities;

- - adjust the engagement in the nut-sector pair;

- - secure the sector shaft bearings from turning by bending the shoulder on the bearings into the holes on the crankcase;

- - assemble the steering mechanism in the reverse order;

- - install the steering mechanism on the car;

- - add oil;

- - install bipod 18 and shaft fork 12 (when installing wedge 10, nut 6 and washers should be on the side of the machined end on fork 8).