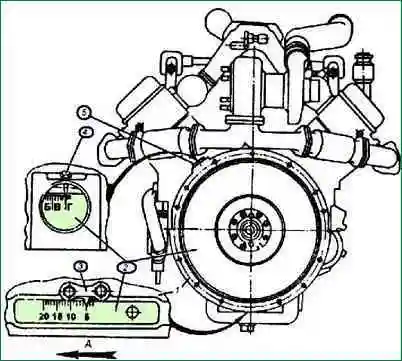

To adjust the fuel injection advance angle, two hatches are provided on the flywheel housing (see Fig. 1), and the angle values \u200b\u200bare marked on the flywheel in two places

For the lower pointer 3 these values are made on the flywheel in numerical terms, and for the side pointer 4 - in letter terms, while the letter "A" corresponds to a numerical value of 20°; the letter "B" -15 °; the letter "B" -10 °; the letter "G" - 5 °.

Rotate the engine crankshaft clockwise (when viewed from the fan side) until the marks on the crankshaft pulley and the distribution gear cover or on the flywheel with the pointer are aligned, corresponding to the fuel injection advance setting angle - 6º-7º.

In this case, the valves in the 1st cylinder must be closed.

You can rotate the crankshaft with a wrench for the crankshaft pulley bolt or with a crowbar for the holes in the flywheel (Fig. 2) with the flywheel housing manhole cover removed.

At the moment of alignment of the marks, the mark "A" on the end of the coupling should be aligned with the tip of the pointer (Fig. 3) or with the risk "B" on the pointer (Fig. 4). If the marks are not aligned, you need to make adjustments.

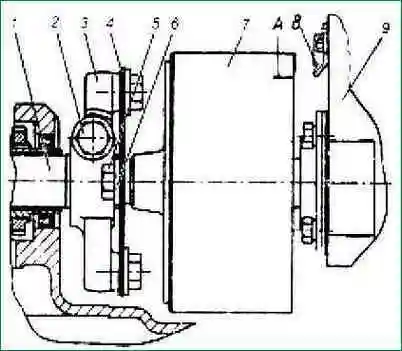

The procedure for adjusting the fuel injection advance angle of the YaMZ-238BE2 and YaMZ-238DE2 engines (Fig. 3):

- - loosen the bolt 2 of the terminal connection: flange 3 - drive coupling half 1;

- - by turning the damper clutch, align the mark on the clutch with the tip of the pointer 8;

- - without knocking down the combined position of the marks, tighten the bolt of the terminal connection to a torque of 16-18 kgf m.

In this case, the deviation of the plate package from the position in one plane should be within ±1 mm.

Measurement should be carried out near the attachment points of the plates.

If corrugations appear on the plates 4, they are eliminated by alternately loosening and subsequent tightening with a torque of 11-12.5 kgf m of four bolts 5 fastening the plates to the coupling half flange and to the damper coupling;

- check if the injection advance angle is set correctly.

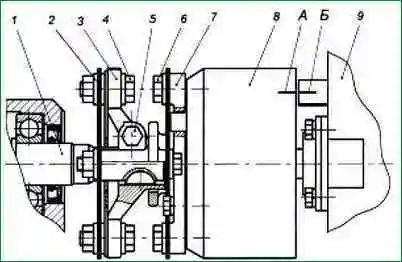

The procedure for adjusting the fuel injection advance angle of the YaMZ-238BE and YaMZ-238DE engines (Fig. 4):

- - check the fit of the coupling half 3 on the drive shaft 1 and the tightening of the terminal bolt 5 (tightening torque 43.2-58.9 N m (4.4-6 kgf m));

- - unscrew (loosen) two bolts 4 and by turning the advance clutch, combine the marks "A" and "B" by means of oval holes on the half-coupling flange;

- - without knocking down the combined position of the marks, tighten the bolts 4 of the drive with a tightening torque of 43.2-58.9 Nm (4.4-6 kgf m).

In this case, the deviation of the plate package from the position in one plane must be within ± 1 mm. Measurement should be carried out near the attachment points of the plates;

- turning the crankshaft, check the correct injection timing.

Mismatch of marks should be no more than one division or 1º of rotation of the crankshaft.

Check the presence of oil in the fuel injection advance clutch (YaMZ-238BE and YaMZ-238DE), and, if necessary, add oil.

For control, set the coupling with holes in the upper position and unscrew the plugs.

Oil should start to flow out of one hole when the coupling is slowly rotated 70º. After topping up the oil plugs wrap.