The cylinder block is the main body part of the engine and is a cast iron with vermicular graphite

The casting is subjected to artificial aging to relieve thermal stress, which allows the block to maintain the correct geometric shapes and dimensions during operation.

Two rows of half-blocks for cylinder liners, cast as one piece with the upper part of the crankcase, are located at an angle of 90° to one another.

The left row of bores for liners is shifted forward (toward the fan) relative to the right by 29.5 mm, which is due to the installation of two connecting rods on each crankpin of the crankshaft.

Each bore has two coaxial cylindrical holes made in the upper and lower chords of the block, along which the cylinder liners are centered, and recesses in the upper zone, forming annular areas for the sleeve collars.

To ensure correct fit of the liner in the block, the parameters of flatness and perpendicularity of the thrust pad under the sleeve shoulder relative to the axis of the centering bores are carried out with high accuracy.

On the lower belt there are two grooves for sealing rings, which prevent coolant from entering the cooling cavity of the block into the cavity of the engine oil sump.

The bosses of the holes for the cylinder head bolts are made in the form of bosses to the transverse walls that form the cooling jacket, and are evenly distributed around each cylinder.

The crankcase part of the block is connected to the main bearing caps with main and tie bolts.

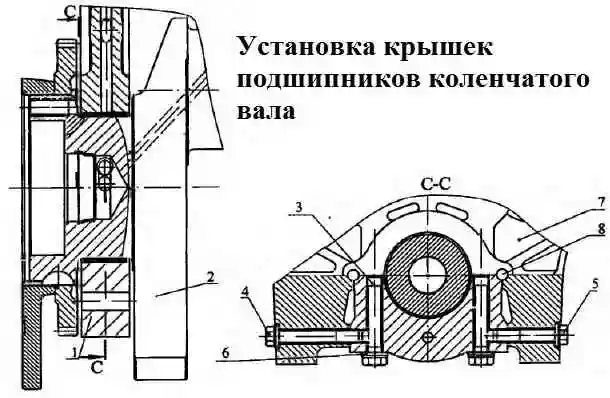

Centering of the main bearing caps is done with horizontal pins 8 (Figure 1), which are pressed into the joint between the block and the caps, but mostly included in the block to prevent them from falling out when removing the caps.

In addition, the cover of the fifth main support is centered in the longitudinal direction by two vertical pins, ensuring accurate alignment of the bores for the crankshaft thrust half-rings on the block and on the covers.

The procedure for tightening the bolts securing the main support covers in accordance with the article - Tightening torques for KAMAZ diesel connections.

Boring of the cylinder block for the main bearing shells is done complete with caps, so the main bearing caps are not interchangeable and are installed in a strictly defined position.

On each cover there is a serial number of the support, the numbering of which begins from the front end of the block.

In the crankcase part of the cylinder block, valve pusher guides are made in the form of bosses.

Closer to the rear end between the fourth and eighth cylinders, to improve coolant circulation, there is a cooling cavity bypass pipe.

At the same time, it also gives the block additional rigidity.

Parallel to the axis of the bores for the crankshaft bearings, there are bores for the camshaft bushings of increased size.

The diameters of the oil channels in the cylinder block have been increased.

In the lower part of the cylinders, bosses for the piston cooling nozzles are cast, integral with the block.

In order to install a filter with a heat exchanger on the right side, the platform for the filter has been enlarged compared to the 740.10 engine, two additional mounting holes and a drain hole from the filter have been introduced.

During the transition period of production development, the 740.30-260 engine can use a cylinder block with modified screw-on pusher guides, with oversized camshaft bushings, without enlarged oil channels, without fixing the main bearing caps on horizontal pins.

Tightening torques of fastening bolts - 73.5-93 Nm (7.5-9.5 kgf m).

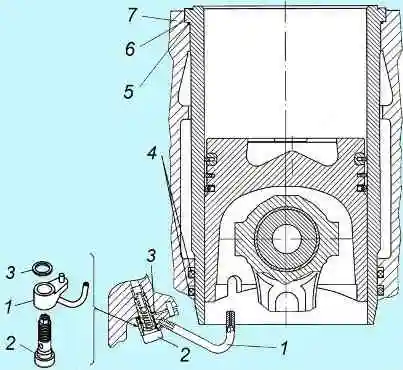

Cylinder liners (Figure 2) are of the “wet” type, easily removable, and are marked 7406 on the conical part at the bottom of the liner.

The cylinder liner is made of gray special cast ironhardened by volumetric hardening and differs in the size of the tempering zone from the heat treatment of sleeves that do not have the specified marking.

Installation of liners without the specified marking on the 740.30-260 engine leads to accelerated wear of the liners and piston rings.

In the connection between the liner and the cylinder block, the cooling cavity is sealed with rubber O-rings.

In the upper part there is a ring 5 in the bore of the liner, in the lower part there are two rings 4 in the bores of the cylinder block.

The microrelief on the liner mirror is a sparse network of depressions and areas with small marks at an angle to the liner axis.

When the engine is running, the oil is retained in the depressions, which improves the running-in of parts of the cylinder-piston group.

When assembling the engine, the cylinder number and the index of the piston version are marked on the non-working protrusion of the end of the liner.

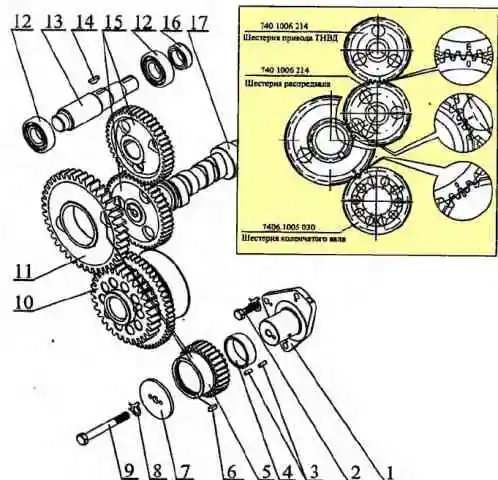

The units are driven (Figure 3) by spur gears and serve to drive the gas distribution mechanism, high-pressure fuel pump, compressor and power steering pump of the vehicle.

The gas distribution mechanism is driven by gear 10 mounted at the end of the crankshaft through a block of intermediate gears, which rotate on two rows of rollers 3, separated by an intermediate sleeve 4 and located on axis 1, fixed at the rear end of the cylinder block.

A gear 15 is pressed onto the end of the camshaft, the angular position of which relative to the shaft cams is determined by a key.

Gear 15 of the high pressure fuel pump (HPF) drive is installed on the injection pump drive shaft 13 and is secured with key 14.

Gears are installed on the engine in a strictly defined position according to the “O” mark on the camshaft drive gear, the “E” mark on the injection pump drive gear and the marks stamped on the gears, as shown in Figure 3.

The fuel injection pump is driven by gear 15, which is in mesh with the camshaft gear 15.

Rotation from the shaft to the injection pump is transmitted through the drive and driven coupling halves with elastic plates, which compensate for the misalignment of the injection pump shafts and the gear wheel.

The gear wheels of the compressor and the power steering pump are engaged with the gear wheel of the injection pump drive.

The crankcase of the units is attached to the rear end of the cylinder block.

In the upper part of the crankcase there are bores into which the compressor and power steering pump are installed.

On the sides of the crankcase there are bosses with holes for draining oil from turbochargers and a hole for the oil level indicator.

The drive of the units is closed by a flywheel housing, attached to the rear end of the cylinder block through the housing of the units.

On the right side of the flywheel housing there is a place for installing a flywheel clamp, which is used to set the fuel injection advance angle and regulate thermal clearances in the gas distribution mechanism.

The lock handle must be in the upper position when the engine is running.

It is moved to the lower position during adjustment work; in this case, the latch is engaged with the flywheel.

In the upper part of the flywheel housing there is a bore into which the rear bearing housing is installed.

At the bottom left side of the crankcase there is a bore into which the starter is installed.

In the middle of the crankcase there is a boring for the crankshaft seal.

In the upper part of the crankcase on the left there is a boss designed for installing a power take-off (PTO). In the absence of POM, the internal surfaces of the boss are not processed.

The rear flange of the flywheel housing is made with mounting dimensions according to SAE1.