We remove the front wheel drives during repair work or if malfunctions occur, such as:

- - noise, knocking from the front axle when the car is moving (especially when turning), usually this defect is associated with wear of the outer hinge parts, less often the inner one;

- - deformation of the shafts of the drive shafts, the defect is caused by impacts with obstacles;

- - grease leakage due to rupture of the protective cover of the inner or outer hinge.

The work must be carried out in an inspection pit or on a lift.

We show the operations using the right drive as an example - its dismantling is more labor-intensive.

Drain the oil from the front axle gearbox.

Unscrew the adjusting nut of the hub bearings and remove the conical bushing.

Disconnect the lower shock absorber mount from the lower arm spring support cup.

Disconnect the lower ball joint from the lower arm of the front suspension.

Move the steering knuckle to the side and remove the tailstock of the outer hinge housing from the hub.

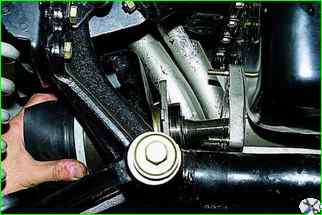

Using a 19 mm open-end wrench, unscrew the bolt securing the front axle bracket to the right bracket of the powertrain support

Remove the bolt

Using a 13 mm head, unscrew the nuts securing the front axle bracket and the bearing cap of the inner hinge housing to the gearbox housing.

We move the front axle mounting bracket

We use a mounting blade to pry the bearing cover of the inner joint housing by the tides

We remove the inner joint housing from the gearbox

Removing the drive assembly

The connection between the bearing cover and the gearbox housing is sealed gasket (the gasket is installed in one position).

We remove the drive on the left side in the same way, only there three nuts secure only the bearing cover.

We install the drive in the reverse order.

The nut for fastening the bearing cover of the inner hinge housing M6x1.25 is tightened with a torque of 19.6-24.5 Nm (2.0-2.5 kgf m).

Tighten the hub bearing adjusting nut to a torque of 19.6 N m (2.0 kgf m), while simultaneously turning the hub in both directions.

After this, loosen the adjusting nut and tighten it again to a torque of 6.86 N m (0.7 kgf m).

Then lower the nut by 20-25˚.

Check the clearance in the bearings: it should be within 0.02-0.08 mm. We lock the nut.