Prepare the car for work. Install it on a lift or in an inspection pit. Disconnect the negative battery terminal.

Remove the intake module screen.

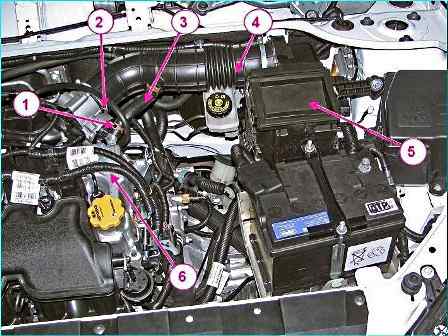

Air filter with intake pipe hose assembly: 1 - upper crankcase ventilation hose clamp; 2 - intake pipe hose clamp; 3 - upper crankcase ventilation hose; 4 - intake pipe hose; 5 - air filter; 6 - cylinder head cover

Using pliers, squeeze clamp 1, Fig. 1, fastenings and disconnect upper hose 3 of crankcase ventilation from branch pipe of cover 6 of cylinder head.

Using a Phillips screwdriver, loosen clamp 2 fastenings and disconnect hose 4 of intake pipe from throttle branch pipe.

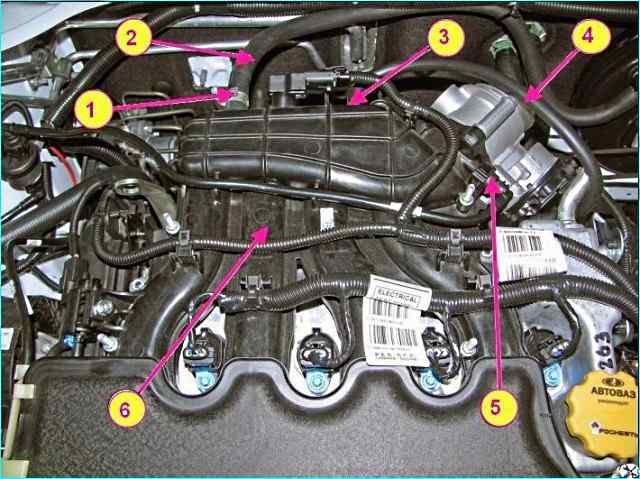

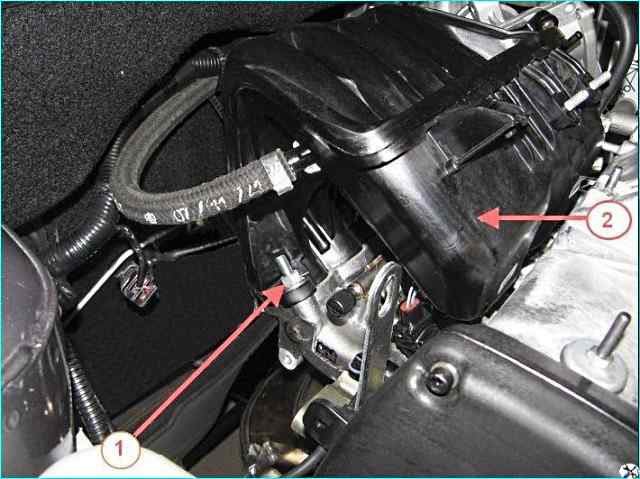

Hoses and tubes suitable for intake module (for engine 21129): 1 - clamp; 2 – brake booster hose; 3 – clamp; 4 – crankcase ventilation tube; 5 – adsorber valve tube tip; 6 - intake module

Using a screwdriver or an 8 mm head, loosen clamp 1, Figure 2, and disconnect hose 2 of the brake booster from module 6 of the intake.

Using pliers, squeeze clamp 3 and disconnect tube 4 of the crankcase ventilation from the intake module.

Press the spring clamps and, moving along the axis of the fitting, disconnect tip 5 of the adsorber valve tube and the tube itself from the intake module.

If the car has a 21129 engine:

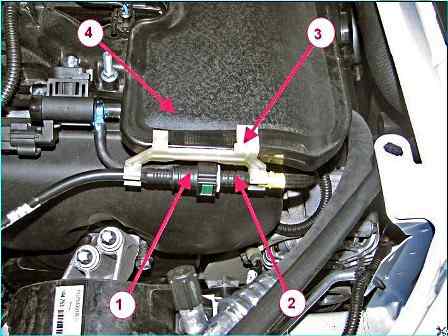

Fuel pipe fastening (for engine 21129): 1 - intermediate fuel pipe; 2 - front fuel pipe; 3 - pipe fastening bracket; 4 - intake module

- disconnect tubes 1 and 2, figure 3, of the fuel line with the mounting bracket 3 in assembly from the intake module 4.

Disconnect the ignition system wiring harness pads from the connectors:

Crankshaft position sensor: 1 - crankshaft position sensor; 2 – ignition system wiring harness

- sensor 1, figure 4, crankshaft position;

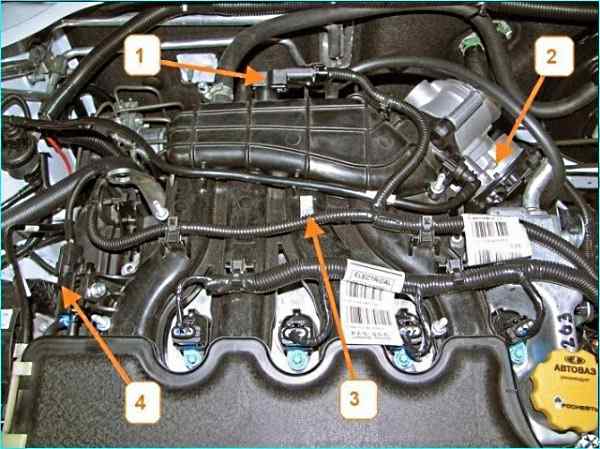

Ignition system wiring harness connections (for engine 21129): 1 - air pressure and temperature sensor; 2 - throttle pipe; 3 - ignition system wiring harness; 4 - intake manifold flap valve

- - sensor 1, figure 5, air pressure and temperature;

- - throttle pipe 2;

- - valve 4 of the intake manifold flap (for engine 21129);

Disconnect the clamps securing the ignition system wiring harness from the intake module and move the harness to the side

If the car is equipped with engine 21129, then:

Connections of the ignition coil wire harness (for engine 21129): 1 - ignition coil wire harness; 2 - clamp; 3 - intake module; 4 – ignition coil

Disconnect the connectors of harness 1, figure 6, from the ignition coils 4, disconnect the clamps 2 from the intake module 3 and move the ignition coil harness to the side.

Using a 10 mm socket, unscrew the three nuts and remove the throttle pipe from the intake module.

Fastening the intake module (for engine 21129): 1 – intake module fastening nut; 2 - special washer; 3 - intake module

Using a 10 mm head, unscrew the two nuts 1, Figure 7, securing module 3 to the cylinder head and remove the special washers.

Disconnect the clamp securing the injector wiring harness from the intake module

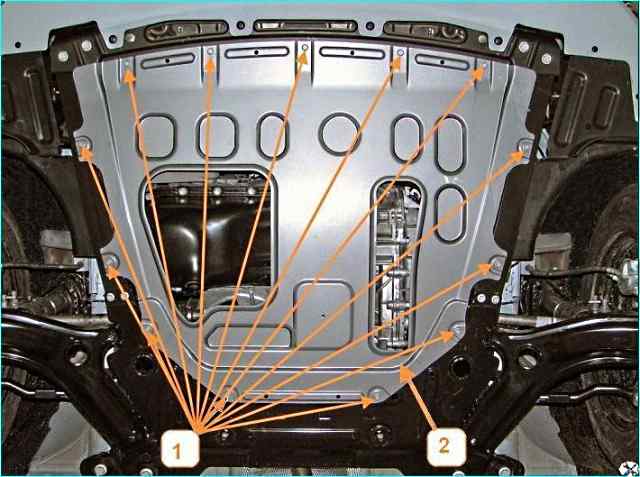

Engine mudguard: 1 - mounting bolt; 2 - engine mudguard

Using a 10 mm socket, unscrew the thirteen bolts 1, Figure 8, for fastening and remove the engine guard 2.

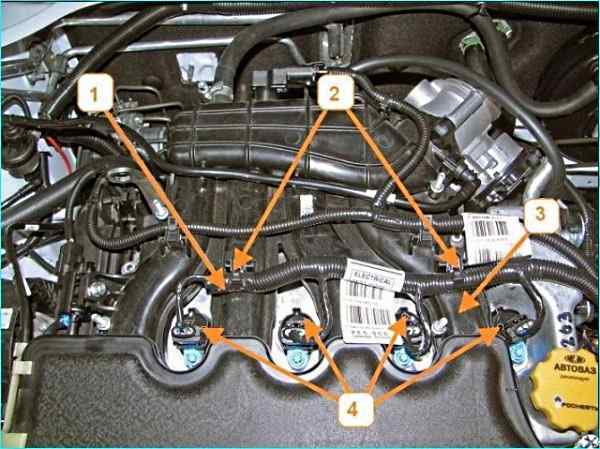

Removing the intake module: 1 - screw; 2 - clamp; 3 - wire harness; 4 - lower crankcase ventilation hose; 5 – clamp; 6 – oil level indicator guide tube; 7 - accessory drive belt

Unscrew screw 1, figure 9, securing tube 6 of the oil level indicator guide to the intake module and remove the tube with the oil level indicator assembly.

Cut clamp 2 securing harness 3 of the wires to the lower hose 4 of the crankcase ventilation.

Using pliers, squeeze clamp 5 and disconnect the lower crankcase ventilation hose from the cylinder block pipe.

Remove belt 7 of the accessory drive (see article on removing the belt).

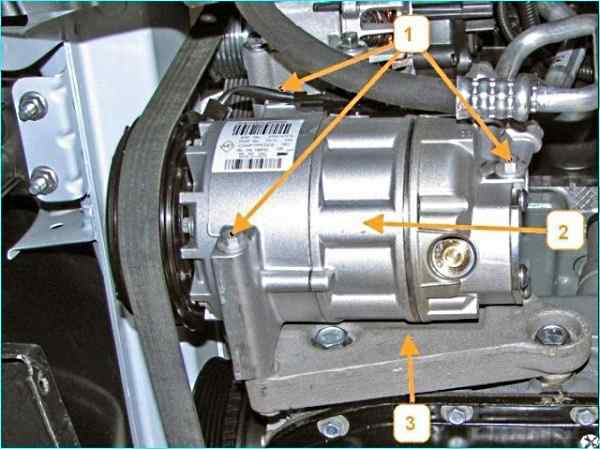

If engine 21129 and air conditioning system are installed:

Removing the air conditioning compressor: 1 - bolt; 2 - air conditioning compressor; 3 - bracket for mounted units

- use a 10 mm head to unscrew the three bolts 1, figure 10, remove the compressor 2 of the air conditioning system without breaking the tightness of the system and hang it on a technological hook.

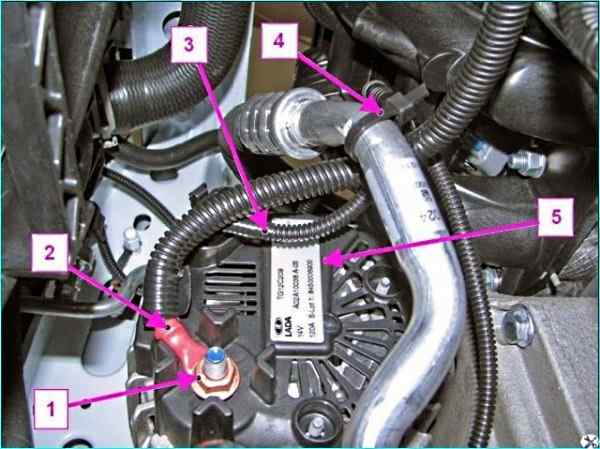

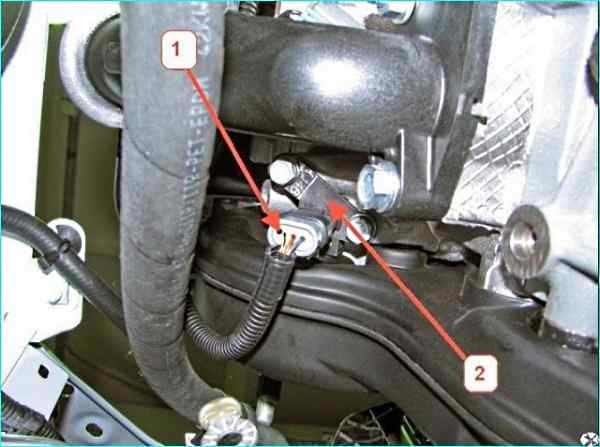

Connecting the wire harnesses to the generator: 1 - nut; 2 - terminal of the wire harness to the generator; 3 - wire harness; 4 - clamp; 5 - generator

Using a 13 mm head, unscrew nut 1, figure 11, fastenings and disconnect terminal 5 of the wiring harness 2 from the generator.

Disconnect the connector of the wiring harness 3 from the generator.

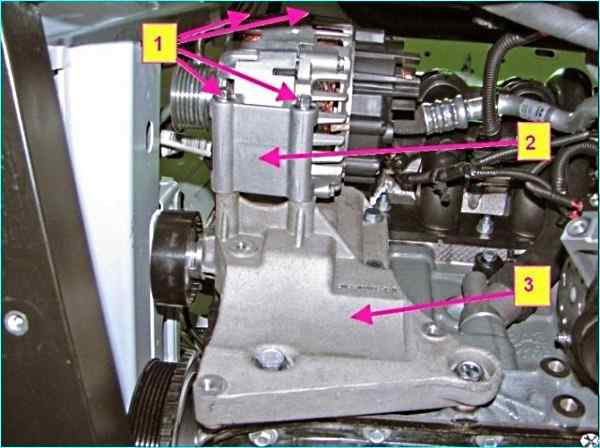

Generator fastening: 1 - bolt; 2 - generator; 3 - bracket for mounted units

Using a 10 mm socket, unscrew the four bolts 1, fastenings and remove the generator 2.

Fastening the terminal of the "ground" wire harness to the bracket for mounted units: 1 - bolt; 2 - terminal of the "ground" wire; 3 - bracket for mounted units

Using a 13 mm head, unscrew bolt 1, Figure 13, securing terminal 2 of the ground wire to bracket 3 of mounted units and disconnect the terminal.

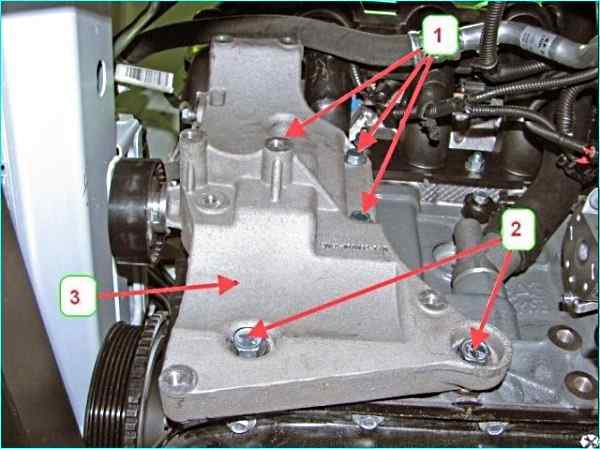

Fastening the terminal of the ground wire harness to the bracket for mounted units: 1 - bolt M8; 2 - bolt M10; 3 - bracket for mounted units

Using a 13 and 17 mm head, unscrew bolts 1 and 2 for fastening and remove bracket 3 for mounted units.

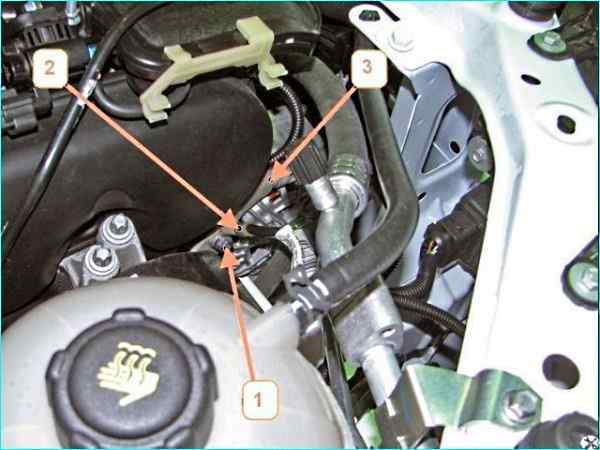

Phase sensor: 1 connector of the wiring harness; 2 - phase sensor

Disconnect block 1, figure 15, of the wiring harness from the 2 phase sensor.

Using pliers and a slotted screwdriver, disconnect the clamp securing the wiring harnesses from the intake module and move the wiring harness to the side.

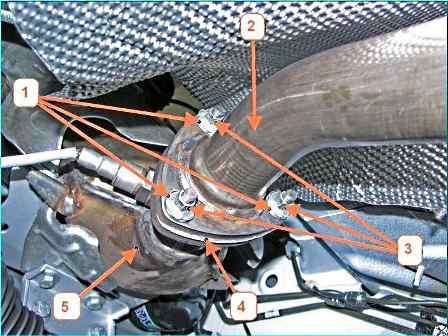

Connecting the additional muffler to the exhaust pipe of the muffler with the neutralizer in the assembly: 1 - lock washer; 2 - additional muffler; 3 - nut; 4 - muffler flange gasket; 5 - muffler inlet pipe with neutralizer assembly

Now, you need to unlock the three washers, Figure 16, locking and unscrew the three nuts 3 of the studs securing the additional muffler 2 to the muffler inlet pipe 5 with the neutralizer assembly, disconnect the additional muffler from the muffler inlet pipe and remove the gasket 4 (use a flat screwdriver, a 10 mm wrench, 10 mm socket, extension and ratchet).

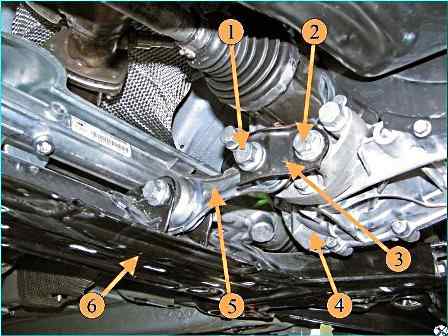

Rear support of the power unit suspension: 1, 2 - bolt; 3 - bracket, 4 - power unit, 5 - rod, 6 - front suspension subframe

Using a 18 mm head, unscrew bolts 1 and 2, Figure 17, fastening rod 5 to power unit 4 and remove bracket 3.

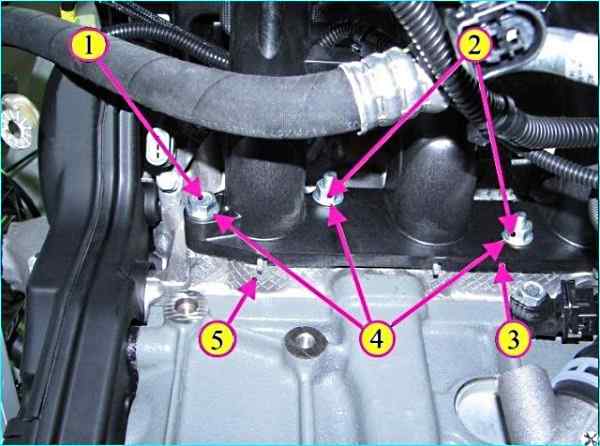

Fastening the intake module: 1 - bolt; 2 - nut; 3 - intake module; 4 - washer; 5 - cylinder head

Using a 13 mm head, unscrew bolts 1 and 2, Figure 18, and three nuts 2 with washers 4 securing the intake module 3 to the cylinder head 5.

Carefully tilt the engine away from the radiator of the cooling system and remove the intake module.

If the car is equipped with engine 11189, then:

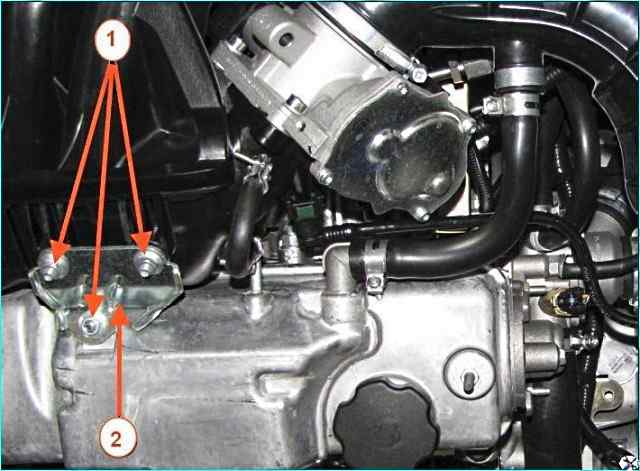

Removing the intake module support bracket (for engine 11189): 1 - support bracket fastening nut; 2 - support bracket

- use a 10 mm head to unscrew the three nuts 1, figure 19 and remove bracket 2.

Intake module (for engine 11189): 1 - intake module fastening nut; 2 - intake module

- with a 13 mm head, unscrew the five nuts 1, Figure 20, securing the intake module from the front shield side and remove the intake module 2.

Installing the intake module

For vehicles with engine 21129:

Carefully tilt the engine away from the radiator of the cooling system and install the module 3, Figure 18, intake on the head of cylinder 5.

Tighten and tighten the two bolts 1 and three nuts 2 with washers 4 securing the intake module.

Tightening torque of bolts and nuts 2.1 - 2.5 Nm (21 - 25 kgf.m) (used: - replaceable head, ratchet, extension, key torque).

Install bracket 3, Figure 17, and bolts 1 and 2 for fastening rod 5 to power unit 4.

The tightening torque of the bolts is 90 - 120 Nm (9…120 kgf.m) (the following is used: replaceable head 18, ratchet, torque wrench).

Install a new gasket 4 on the flange of the inlet pipe 5, Figure 16, with the neutralizer assembly, attach the additional muffler 2, install lock washers 1.

Tighten and tighten the three nuts 3 of the studs for fastening the additional muffler to the inlet pipe and lock.

The tightening torque of the nuts is 21 - 25 Nm (2.1 - 2.5 kgf.m) (the following is used: - replaceable head 10, ratchet wrench, wrench torque, blunt chisel, hammer).

Connect block 1, figure 15, of the wiring harness to the 2-phase sensor and the clamp for fastening the wiring harness to the intake module.

Install bracket 3, figure 14, of the mounted units and secure with bolts.

Bolt tightening torque: 1 (M8) – 15 - 24 Nm (1.5 - 2.4 kgf.m); 2 (M10) – 33 - 52 Nm (3.3 - 5.2 kgf.m) (used: - replaceable head 13, 17, extension, ratchet, torque wrench).

Install terminal 2, Figure 13, ground wires on bracket 3 of attachments and secure with bolt 1.

Bolt tightening torque 18 - 22 Nm (1.8 - 2.2 kgf.m) (used: - replaceable head 13, ratchet wrench, torque wrench).

Install generator 2, Figure 12.

For vehicles with engine 21129 and air conditioning system

Install compressor 2, Figure 10, air conditioning system.

For vehicles with engine 21129

Install the belt 7, Fig. 9, of the accessory drive.

Install the lower crankcase ventilation hose 4 on the cylinder block pipe and secure with a clamp 5 (use pliers).

Fix the wiring harness 3 to the lower crankcase ventilation hose 4 with a new clamp 2.

Install the oil level indicator guide tube 6 and secure with screw 1 to the intake module.

The tightening torque of screw 3 is 8 Nm (0.3 - 0.8 kgf.m) (Phillips socket, torque wrench).

Install the mudguard 2, Fig. 8, of the engine and secure with bolts 1 (replaceable head 10, ratchet and extension).

Install two washers 2, figure 7, screw in and tighten two nuts 1 for fastening the intake module 3 to the cylinder head.

Tightening torque of nuts 3 - 5 Nm (0.3 - 0.5 kgf.m) (used: - replaceable head 10, ratchet, extension, torque wrench).

Attach the clamp for fastening the injector wiring harness to the intake module.

Install the throttle th branch pipe onto the intake module and secure with three nuts. Tightening torque of intake module mounting nuts 5 - 8 Nm (0.5 - 0.8 kgf.m)

Connect harness connectors 1, Fig. 6, of wires to ignition coils 4, attach clamps 2 to intake module 3.

Connect ignition system wiring harness connectors to sensor and actuator connectors in the reverse order of removal.

Attach harness clamps to intake module.

Connect pipes 1 and 2, Fig. 3, of fuel line with mounting bracket 3 in assembly to intake module 4.

For vehicles with engine 11189

Install intake module 2, Fig. 20, on intake pipe. Screw on and tighten nuts 1 for fastening the intake module from the front shield side. Tightening torque of nuts 7 - 15 Nm (0.7-1.5 kgf.m).

Install bracket 2, Figure 19, and secure with nuts 1. Tightening torque of nuts 2 - 5 Nm (0.2-0.5 kgf.m).

For vehicles of all configurations

Attach tip 5, Figure 2, of the adsorber valve tube by moving along the axis of the fitting until the spring clip clicks. After installation, check the reliability of the tube fixation.

Install the adsorber valve tube into the fastening elements on the intake module 6.

Connect tube 4, Fig. 2, crankcase ventilation, hose 2 of the brake booster, hose 4, Fig. 1, intake pipe and upper hose 3 of the crankcase ventilation in the reverse order of removal (Phillips screwdriver, pliers).

Install the intake module screen.

Connect the ground wire terminal to the battery.