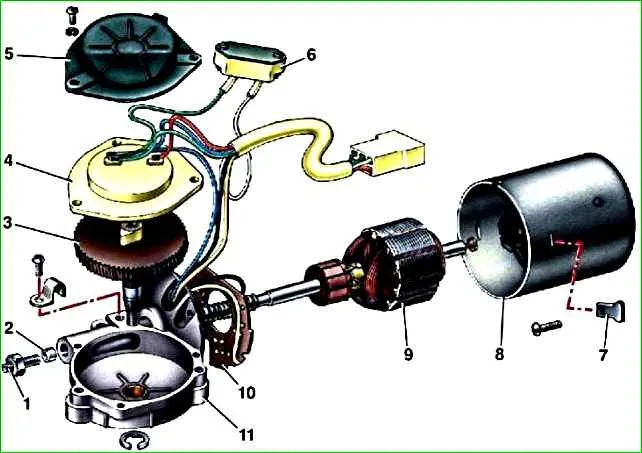

To disassemble the gear motor, unscrew the screws securing the cover 6 of the gearbox and remove it together with the panel 4 of the limit switch

Then unscrew the screws securing the housing 11 of the gearbox to the housing 8 of the electric motor and disconnect them.

Remove the anchor 9 of the electric motor.

To remove the gear 3 of the gearbox, unscrew the crank fastening nut, remove the retaining ring from the axle and remove the axle with the gear and washers from the housing.

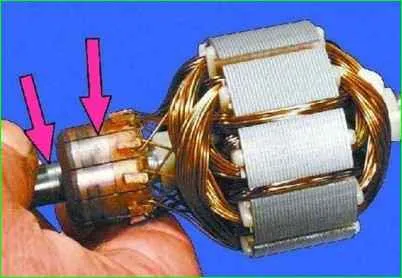

After disassembling, blow out the internal cavities of the electric motor with compressed air to remove carbon dust deposits and check the condition of the brushes and commutator.

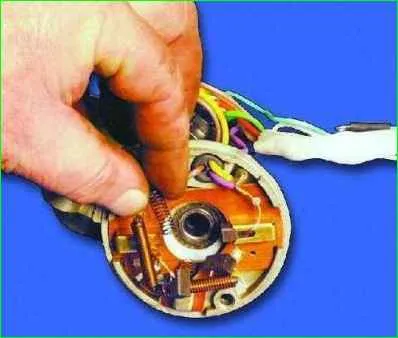

The brushes should move freely in the brush holders without jamming, and the springs should be intact and have sufficient elasticity.

Clean the commutator with fine-grained sandpaper, and then wipe it with a clean rag lightly lubricated with technical petroleum jelly.

If the commutator is badly burnt or worn out, it is better to replace the gear motor with a new one. Check for signs of seizure on the journals of the armature shaft.

If necessary, clean them with fine-grained sandpaper.

When assembling, move the brushes away from the commutator so as not to break them or damage their edges, and insert the armature into the housing with special care, avoiding hitting the armature on the poles so as not to break them.

After assembly, to center the bearings, tap the gearmotor housing with a wooden hammer, and then check it on the stand.

When installing the crank, position it so that in the final position it is parallel to the short rod of the wiper and directed towards the electric motor.

Data for checking the gearmotor

Speed of rotation of the gearmotor shaft at a supply voltage of 14 V, a load torque of 1.47 N m (0.15 kgf m) and an ambient temperature of 25±10 ° C, min -1 :

- - first (small) 30–40

- - second (large) 55–70

Current consumption at the above load torque, A, no more than:

- - at first speed 3.5

- - at second speed 5

If the brush springs are damaged or have lost their elasticity, replace them.

Check the ease of movement of the brushes in the brush holder. They should move freely, without jamming.

Replace worn or chipped brushes. When replacing, solder the terminals of the new brushes to the brush holder.

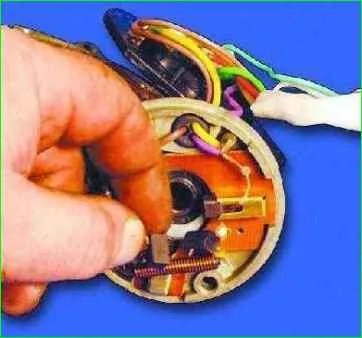

Clean the collector with fine sandpaper if it is dirty or has scratches, etc.

If the collector is badly worn or burnt, replace the anchor or gearbox with the electric motor as an assembly.

If you find signs of seizing on the anchor journals, clean the journals with fine sandpaper.

Replace the gear reducer with badly worn or broken teeth.

Clean burnt or oxidized contacts of the self-stop mechanism with fine sandpaper.