Inspection is best done on a lift or inspection pit

We hang up the wheels one by one and check the condition of the wheel hub bearings

The wheel should rotate evenly by hand, without jamming or knocking.

We take the wheel in a vertical plane and alternately sharply pull the upper part toward us, and the lower part away from us, and vice versa. We make sure there is no play.

If there is play on the front wheel, ask an assistant to press the brake pedal.

If the play disappears, it means the hub bearing is faulty. And if the play remains, it means the ball joint or silent block of the suspension arm is worn out.

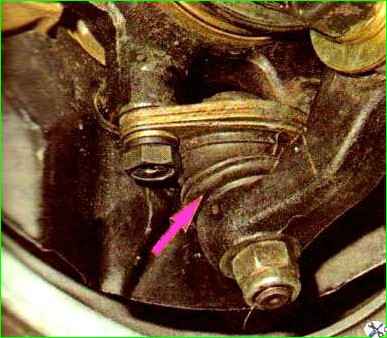

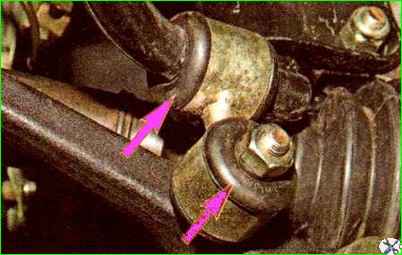

Check the condition of the protective boots of the ball joints.

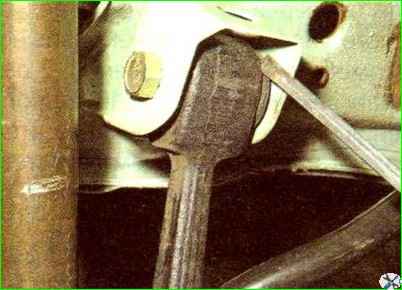

Leaning with a powerful screwdriver or a mounting spatula on the front suspension arm bracket, we try to move the arm head along the axis of the bolt, first in one direction and then in the other.

If the lever head moves freely, the silent block of the lever is worn or damaged and must be replaced.

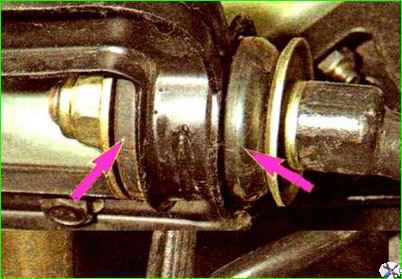

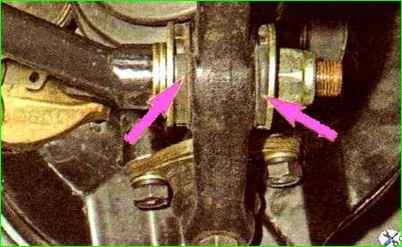

Checking the condition of the silent blocks of the front braces

Check the condition of the silent blocks at the rear ends of the guy wires.

Tears, cracking and swelling of rubber silent blocks are unacceptable.

Inspecting the pillows

Checking the silent blocks of the struts - stabilizer bars

Condition of the silent blocks of the rear suspension beam

Check the condition of the springs, telescopic struts and shock absorbers of the front and rear suspensions.

Tears, cracks and severe deformation of rubber bushings, cushions and shock absorber compression buffers are unacceptable.

Liquid leakage from shock absorbers and telescopic struts is not allowed.

Slight “fogging” of the shock absorber in the upper part, while maintaining its characteristics, is not a malfunction.

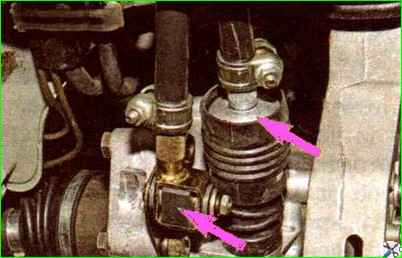

If the rubber element of the upper support of the front suspension telescopic strut settles or is destroyed, the support must be replaced.

Check the condition of the hinges and the protective cover of the gear shift rod and jet rod

We hang the front part of the car on reliable supports.

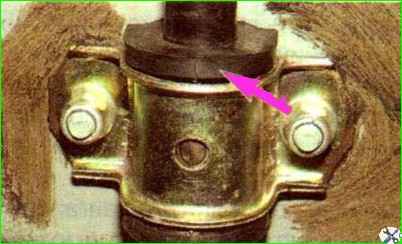

Rotating and turning the wheels, we inspect the protective covers of the external and internal hinges of the wheel drives, and check the reliability of their fastening with clamps.

Cracked, torn or lost elasticity covers must be replaced.

We check that there is no oil leakage from the gearbox through the seals of the internal drive joints. If there is a leak, replace the seals.