In order not to confuse the terminals on the ignition coil (ignition module), it is more convenient to change the high-voltage wires one by one

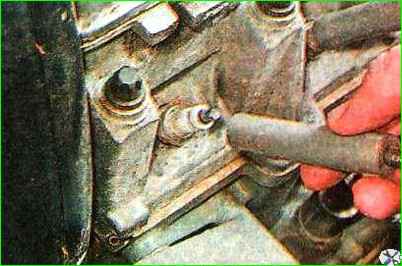

Disconnect the high-voltage wires from the spark plugs.

Disconnect the tips of the high-voltage wires from the ignition coil

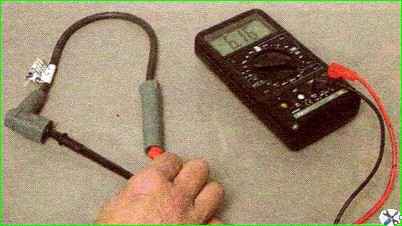

Using a tester (in ohmmeter mode) we measure the resistance of the wires.

For serviceable wires, the resistance (depending on the length) should be in the range of 3.5-10.0 kOhm. No more than 15 kOhm

High-voltage wires should be replaced as a set.

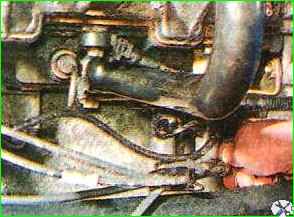

We connect the wires to the spark plugs and the ignition coil in accordance with the cylinder serial numbers marked on the wires and on the ignition coil.

It is necessary to connect the wires to the ignition coil only in accordance with the serial number of the cylinder.

The insulation of the wires is marked with the serial number of the cylinder.

Checking and replacing spark plugs

Candles can be checked with a special tester, which is sold in a spare parts store.

Or, with the help of an assistant, you can check the candles by turning them out and inserting them into the tips and positioning them as shown in the picture

The assistant turns on the starter, while you watch the spark between the electrodes of the spark plugs.

Of course, these methods cannot show the full characteristics of candles.

Since the spark plug must be subjected to special testing in a special installation.

On a special installation, the spark plug is checked for pressure, temperature, insulation and sparking, etc.

When purchasing spark plugs, it is advisable to check them in the store with a tester and visually inspect them for deformations and cracks in the insulator.

Spark plugs should be replaced every 30,000 km.

You should use spark plugs А17ДВРМ or their foreign analogues - LR15YC-1 (BRISK) and WR7DCX (BOSCH).

To complete the job, you will need a special socket wrench for 21 mm spark plugs.

Disconnect the high-voltage wire of the spark plugs.

Wipe with a rag and blow with compressed air from a tire pump the area where the spark plug is installed.

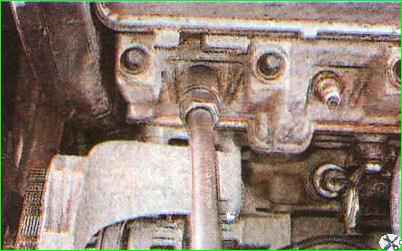

Use a 21 mm socket wrench for spark plugs to unscrew the spark plug

Before installing the spark plug, use a set of round feeler gauges to check the gap between its electrodes. The gap should be 1.0-1.15 mm.

Adjust the gap by bending the side electrode.

To avoid damaging the threads in the cylinder head, you should first screw the spark plug in by hand and then tighten it by inserting the wrench into the wrench extension. The spark plug tightening torque is 30-40 Nm.

A poorly tightened spark plug can fly out during operation and damage the threaded part of the spark plug hole in the cylinder head. But you can’t overtighten the candle either.

Wrap the spark plug into the cylinder head.

We similarly replace the spark plugs of the remaining cylinders, and connect high-voltage wires to them.