Removing the gearbox tie rod

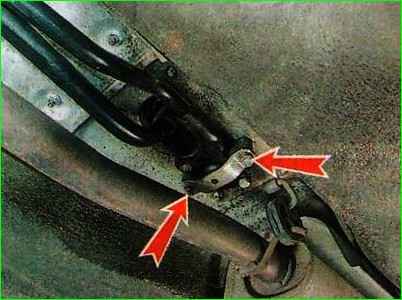

Use a 13 mm socket wrench to unscrew the two nuts securing the bracket

Remove the bracket

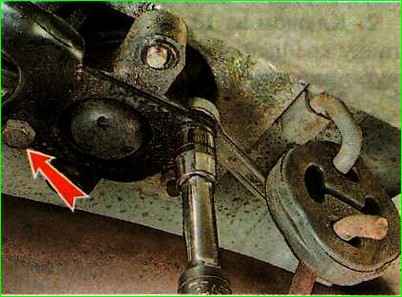

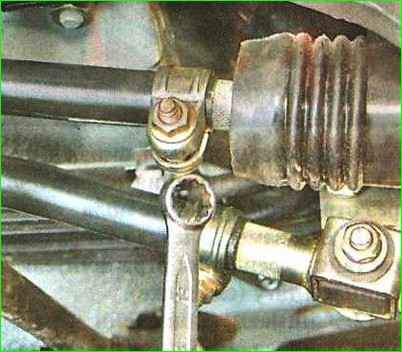

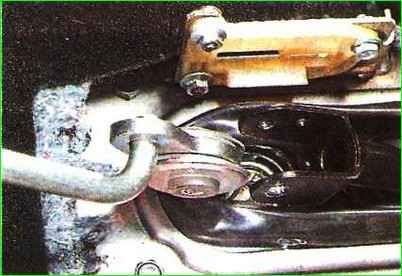

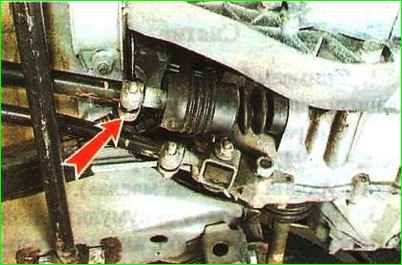

Using a 13 mm socket wrench, unscrew the bolt securing the torque rod to the base of the ball joint of the gearshift lever, holding the bolt nut with a 13 mm spanner.

Also unscrew the second bolt securing the jet rod.

We remove the rod from the gear shift lever support.

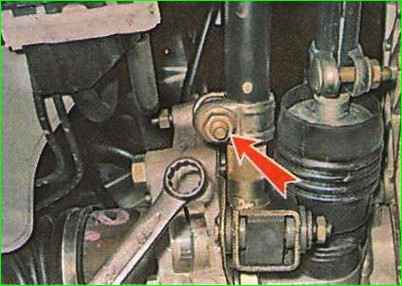

Use a 13 mm wrench to loosen the torque clamp.

Having disconnected its tip from the rod, remove the rod.

If necessary, use a 19 mm socket wrench to unscrew the two nuts securing the torque arm bracket, holding the bolt heads with a wrench of the same size.

Remove the bracket assembly with the tip of the jet thrust

Install the jet thrust in the reverse order.

Removing the gearbox shift mechanism

Removing the gear shift mechanism drive may be necessary when replacing faulty parts (for example, to replace a torn drive rod boot).

To complete the work, you will need an assistant, as well as an inspection ditch or a lift.

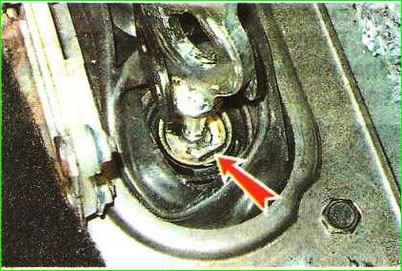

Clean the threads of the clamp bolt with a wire brush. We treat the junction of the rod with the hinge and the bolt with penetrating lubricant.

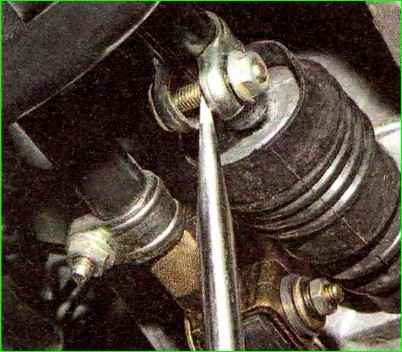

Use a 13 mm wrench to loosen the clamp bolt nut.

Use a screwdriver to open the clamp and move it along the rod.

Use a screwdriver to open the rod.

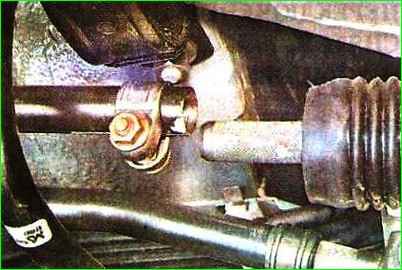

After wiping the connection between the rod and the hinge with a rag, we mark the relative position of the drive rod and the hinge.

Disconnect the rod from the hinge.

Disconnect the torque rod from the base of the ball joint of the gear shift lever.

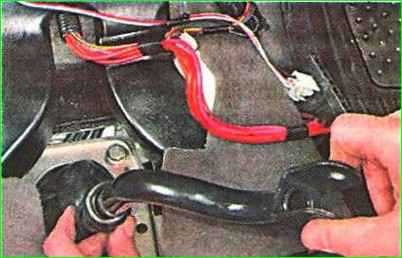

In the car interior, remove the lining of the floor tunnel.

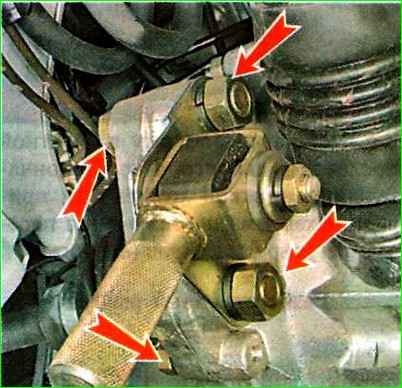

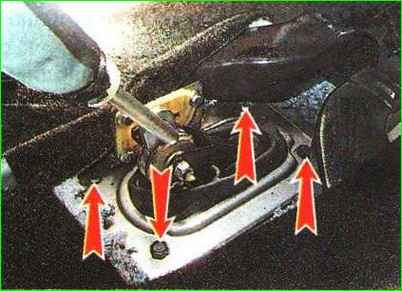

Using a 13 mm wrench, unscrew the four bolts securing the gear shift lever support to the body.

Remove the drive downwards, bringing the gear shift lever out through the hole in the floor tunnel.

To replace the cover, unscrew the nut securing the limiter and remove the rod (see below).

Remove the bracket and drive rod cover. We replace the torn cover.

Install the drive in reverse order.

Replacing the transmission drive rod

To replace some parts (for example, rods), you can but partially disassemble the drive, do not remove it from the car.

Replacement of the drive rod may be necessary if it is deformed and if, due to corrosion or other damage, it is not possible to reliably connect the rod to the joint on the gearbox.

Disconnect the drive rod from the gearbox (see above) and remove the steel clamp from the rod.

Use a 13 mm wrench to unscrew the nut securing the limiter.

Remove the limiter from the lever.

Remove the lever from the traction fork

To remove the drive rod, lubricate it with soapy water and remove it from the hole in the cover

Install the thrust in the reverse order.

Before final tightening of the gearshift mechanism drive rod clamp, adjust the drive (see below).

Disassembling the gearbox drive lever support

The work can be done by removing the gear shift drive from the car (see above) or by disassembling the support directly on the car.

Disconnect the drive rod from the gear shift lever.

The work can be done by removing the gear shift drive from the car (see above) or by disassembling the support directly on the car.

Disconnect the drive rod from the gear shift lever.

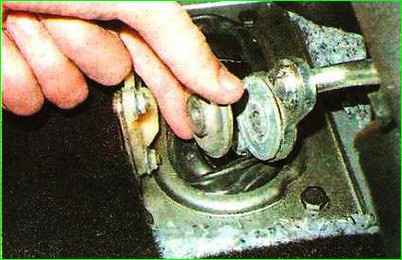

Remove the metal washer

Remove the plastic washer

Take out the metal spacer sleeve

Remove the washers on the other side of the lever

Use a slotted screwdriver to pry up and remove the retaining ring of the ball joint of the lever

Remove the lever from the base of the support

Take the spring out of the support

If necessary, remove the support from the lever and replace damaged parts

Assemble the lever support in the reverse order, lubricating the parts with technical petroleum jelly or other grease.

During assembly, we also lubricate the washers and the lever bushing.

Assemble the lever support in the reverse order, lubricating the parts with technical petroleum jelly or other grease.

During assembly, we also lubricate the washers and the lever bushing.

Adjusting the gearbox drive

The drive has a device that blocks erroneous engagement of reverse gear instead of first gear.

To adjust the drive, a special template is required, but if it is not there, the drive can be adjusted with the help of an assistant.

The gearbox must be in first gear.

If the plastic cover on the bracket prevents the gear from engaging, it should be removed (by unscrewing two nuts and a bolt).

Loosen the clamp and the drive rods of the gear shift mechanism (see above).

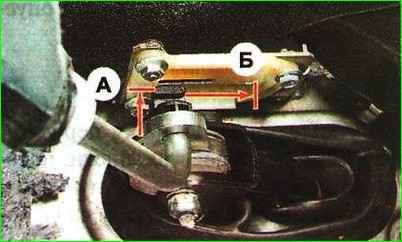

We move the gear shift lever so that its limiter touches the plastic lining of the bracket “A”, and then move the lever forward, but so that the limiter does not move beyond the cutout of the lining “B”.

Hold the lever in this position, while an assistant tightens the metal rod clamp at a distance of 2-3 mm from the end

By engaging reverse gear, we make sure that the gear shift mechanism drive is working.

After pressing the lever from above, its limiter should be opposite the wide part of the slot in the plastic lining of the bracket, and when moving the lever to the left, the limiter should enter the slot without clinging to its edges.

The freedom of movement of the limiter inside the slot should be enough to engage reverse gear

If the limiter clings to the edges of the slot or the limiter rests against the slot at the end of the stroke, and the reverse gear is not yet engaged, it is necessary to repeat the adjustment, slightly changing the position of the rod on the hinge rod.

After completing the adjustment, install the removed parts.