Maintenance of Kamaz transfer case

Maintenance of the transfer case includes checking and tightening the crankcase fastenings and its covers, checking and, if necessary, adjusting and lubricating control drives, maintaining the required oil level in the crankcase, periodically changing the oil, as well as eliminating malfunctions identified during operation.

Oil is poured to the level of the control hole located on the rear wall of the box housing.

Oil is drained through a hole in the lower part of the crankcase.

There is a magnetic plug installed in the drain hole, which is recommended to be thoroughly washed in kerosene when changing the oil.

5.4 liters of transmission oil used for drive axles are poured into the transfer case housing.

Increased noise in the transfer case can be explained by increased wear of the gears and increased displacement of the shafts in the axial direction, which is associated with wear of the bearings or lack of oil in the transfer case housing.

If there is increased noise, you need to check the adjustment of the bearings of the primary and intermediate shafts, check the level and, if necessary, add oil to the crankcase.

The transfer case gears do not turn off due to damage to the membranes of the pneumatic chambers or a break in the pneumatic electric valve circuit.

If these malfunctions are detected, it is necessary to replace the damaged membrane, eliminate the open circuit, and eliminate the jamming of the rod.

If an air leak is detected in the pipeline connections, it is necessary to tighten the connections and replace worn parts.

If oil leaks through the seals and cover connectors, replace worn or damaged seals, tighten the cover bolts and replace the gaskets.

At service 2:

- - check by external inspection that there is no oil leakage through the transfer case shaft seals;

- - secure the transfer case and power take-off;

- - bring the oil level in the transfer case housing to normal;

- - clean the safety valves from dirt.

At service C:

- - secure the transfer case flanges. Additionally, in the fall, change the oil in the gearbox crankcase.

Changing the oil in the transfer case

Oil should be poured through the upper hole in the crankcase, closed with a conical plug.

Check the oil level at the bottom hole, also closed with a plug.

The oil must be drained through the hole in the lower part of the crankcase cover by unscrewing the magnetic plug 27 (see Fig. 1)

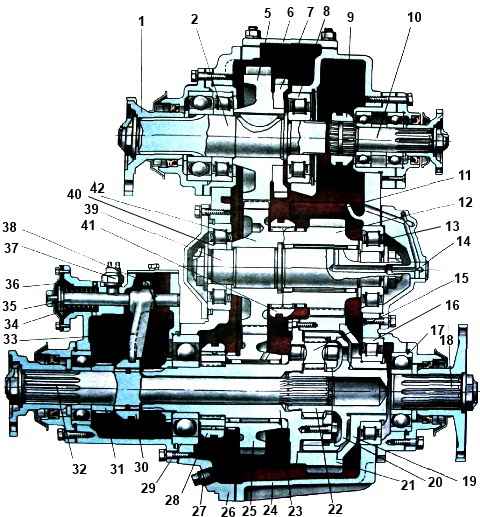

Transfer case: 1 - input shaft flange; 2 - input shaft; 3, 4, 8, 13. 16, 17, 29, 40 - bearings; 5 - drive gear; 6 - top hatch cover; 7 - power take-off gear; 9 - power take-off clutch; 10 - power take-off; 11 - oil sump; 12 - gear wheel of the lowest mulligan; 14 - bearing cover; 15 - satellite; 18 - rear axle drive shaft; 19 - rear differential race; 20 - main gear; 21 - differential low gear gear; 22 - sun gear; 23 - front cage; 24- transfer case housing; 25 - top gear; 20 - transfer case housing cover; 27 - magnetic plug; 28, 30. 41 - couplings; 31 - drive gear of the electric speedometer converter drive; 32 - front axle drive shaft; 33 - fork; 34 - spring; 35 - rod; 36 - membrane; 37 - switch; 38 - lock bolt; 39 - intermediate shaft; 42 - constant mesh gear

When changing the oil, it is necessary to rinse and clean the magnet.