Maintenance of the clutch consists of periodically checking and adjusting the clutch supply, as well as tightening the fastening connections of the pneumatic amplifier and checking the tightness of the drive

In addition, in accordance with the technological map, the release fork shaft supports and the release clutch bearing are lubricated in the clutch.

To prevent lubricant from getting into the clutch housing, when lubricating these points you should not make more than three strokes with a syringe.

Adjusting the clutch drive involves checking and setting the free travel of the clutch pedal, the free travel of the clutch release clutch and the full travel of the pneumatic booster pusher.

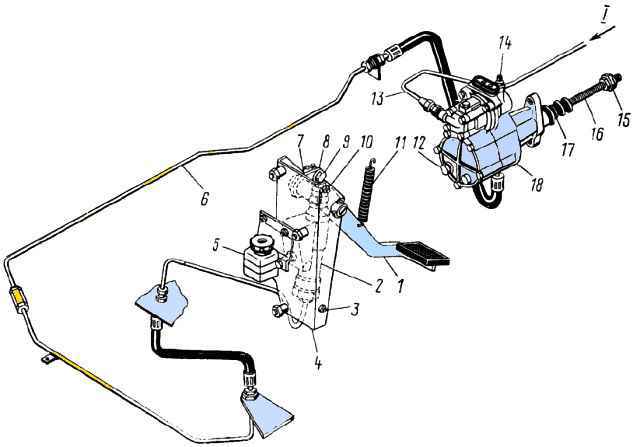

The free play of the clutch release clutch is checked by manually moving the fork shaft lever from the adjusting spherical nut 15 (see figure) of the pneumatic booster pusher (with the spring disconnected from the lever).

If the free play of the lever, measured at a radius of 90 mm, is less than 3 mm, it should be adjusted with a spherical pusher nut to 3.7-4.6 mm, which corresponds to a free play of the clutch release of 3.2-4 mm.

The full stroke of the pneumatic booster pusher must be at least 25 mm.

Check the full stroke of the pusher by pressing the clutch pedal all the way.

With a smaller stroke value, complete disengagement of the clutch is not ensured.

If the pusher travel is insufficient, check the free play of the clutch pedal, the amount of fluid in the clutch master cylinder reservoir and, if necessary, pump the clutch hydraulic system.

The free play of the pedal, corresponding to the start of operation of the master cylinder, should be 6-15 mm. Measure it in the middle part of the clutch pedal area.

If the free play goes beyond the limits specified above, adjust the gap “B” between the piston and the master cylinder piston pusher with an eccentric pin 9, which connects the upper eye of the pusher 8 to the pedal lever 7.

When adjusting the gap, the tension spring 11 should press the clutch pedal against the upper stop 10.

By rotating the eccentric pin of the drive, ensure that the movement of the pedal from the top stop to the moment it touches the piston pusher is 6-15 mm, after which the castle nut is tightened and pinned.

The full travel of the clutch pedal should be 185-195 mm.

The main malfunctions of the clutch and its drive are incomplete engagement (clutch slipping), incomplete disengagement (noise when shifting gears), impaired smoothness of clutch engagement and increased pedal effort when disengaging the clutch.

Incomplete engagement of the clutch and, as a consequence, its slipping under load occurs when the pressure springs are weakened, there is no clearance between the thrust ring of the release levers and the end of the release clutch bearing, oiling and significant wear of the driven disks.

To eliminate this malfunction, it is necessary to adjust the free play of the clutch, checking it against the free play of the clutch fork shaft lever, as indicated above.

If lubricant gets on the friction surfaces, there is severe wear or destruction of the friction linings, it is necessary to remove the clutch from the engine and replace the friction linings or driven discs assemblies.

Incomplete disengagement of the clutch (the clutch “drives”) leads to difficulty engaging gears in the box, since the drive does not provide the required full stroke of the clutch fork shaft lever.

To eliminate the malfunction, it is necessary to achieve full travel of the clutch fork shaft lever, as described above.

Incomplete disengagement of the clutch also occurs when the driven disks are deformed or their hubs are stuck on the splines of the input shaft of the gearbox, as well as when air gets into the hydraulic drive system, leakage of the working fluid and an increase in the free play of the clutch pedal.

To eliminate the malfunction, it is necessary to remove air from the hydraulic system; check and eliminate leakage of working fluid; check and, if necessary, adjust the free play of the clutch pedal.

If a noise (squeaking) appears when you press the clutch pedal, this indicates a lack of lubrication or failure of the clutch bearing disengaging the clutch.

If air gets into the system, it must be bled.

To do this, a special hose is put on the head of the bypass valve 14 (Fig. 1), the free end of which is lowered into a vessel with working fluid.

By unscrewing the bypass valve by ½.-1 turn, remove air from the system by successive (every 0.5-1 s) sharp presses of the clutch pedal all the way.

In this case, it is necessary to monitor the liquid level in the tank and constantly add it, not allowing the level to fall below 40 mm from the upper edge of the neck. Otherwise, air will enter the system through the master cylinder.

Pump the system until air and liquid flowing through the hose stop emitting.

After bleeding is complete, close the bypass valve with the pedal pressed all the way.

Impaired smooth engagement, delayed engagement of the clutch when starting from a standstill and changing gears, jamming in the clutch drive is usually associated with swelling of the sealing cuffs of the hydraulic drive and loss of tightness due to the use of low-quality working fluids, as well as with the faulty operation of the follower device in the pneumatic amplifier .

When operating vehicles at low temperatures, a significant increase in the viscosity (solidification) of the working fluid in the drive can occur, which impairs its performance.

In these cases, it is necessary to replace the cuffs and fill the hydraulic drive system with clean Neva or Tom brake fluid.

At service 2:

- - tighten the bolts securing the pneumatic clutch drive booster:

- - check by external inspection the tightness of the clutch drive, if necessary, eliminate the leak and bleed the drive hydraulic system;

- - check the action of the release springs of the clutch pedal and the clutch release fork shaft lever, correct the faults if necessary;

- - adjust the clutch drive;

- - lubricate the clutch release clutch bearing and the clutch release fork shaft bushing;

- - check the fluid level in the clutch compensation tank and add if necessary;

- - drain the condensate from the air-hydraulic booster by unscrewing plug 12 (see Fig. 1).

Adjusting the clutch drive consists of checking and adjusting the free play of the clutch pedal, the free play of the clutch release clutch and the full travel of the pneumatic hydraulic booster pusher.

Checking the free play of the clutch release clutch is carried out by manually moving the fork shaft lever from the adjusting spherical nut 15 of the pusher 16 of the pneumatic hydraulic booster of the clutch drive (in this case, it is necessary to disconnect the spring from the lever).

If the free play of the lever, measured at a radius of 90 mm, is less than 3 mm, then adjust it with the spherical nut of the pneumatic hydraulic booster pusher to a value of 3.7-4.6 mm, which corresponds to a free play of the clutch release of 3.2-4 mm.

Then check the full stroke of the pusher of the pneumatic hydraulic booster by pressing the clutch pedal all the way, while the full stroke of the pusher must be at least 25 mm; with a smaller stroke, complete disengagement of the clutch is not ensured.

If the pusher stroke of the pneumatic hydraulic booster is insufficient, check the free play of the clutch pedal, the amount of fluid in the master cylinder and clutch reservoir, and, if necessary, bleed the clutch hydraulic system.

The free play of the pedal, corresponding to the start of operation of the master cylinder, should be 6-12 mm.

It should be measured in the middle part of the clutch pedal area.

If the free play is outside the limits specified above, adjust the gap “A” between the piston and the master cylinder piston pusher.

Adjust the gap between the piston and the master cylinder piston pusher using eccentric pin 9 (see Fig. 1), which connects the upper eye of the pusher 8 to the pedal lever 7.

Adjust the gap when the tension spring presses the clutch pedal against the upper stop 10.

Turn the eccentric pin so that the pedal moves from the top stop until the pusher touches the piston by 6-12 mm, then tighten and cotter the castle nut.

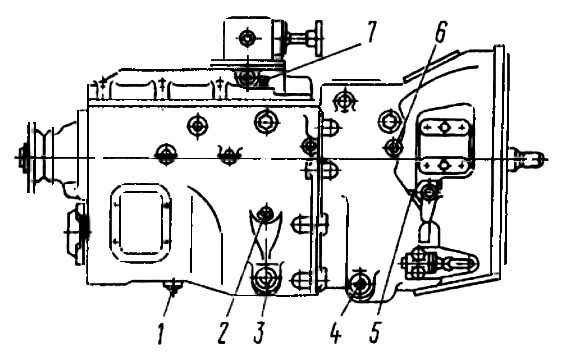

Lubricating the clutch

Lubrication points: 1 - drain plug; 2 - filler plug with oil level indicator; 3, 4 - drain plugs with a magnet; 5 - support grease fitting; 6 - release bearing grease nipple; 7 - breather

Lubricate the clutch release fork shaft bushings through two grease nipples 5, and the clutch release clutch bearing through grease nipple 6, making no more than three strokes with a syringe. Otherwise, excess lubricant may get into the clutch housing.

Level control Check the Neva fluid in the compensation tank of the main cylinder visually.

The normal liquid level in the tank corresponds to 15-20 mm from the top edge of the tank. The total fluid volume in the clutch hydraulic drive is 380 cm 3.

During service “C” (autumn), change the fluid in the clutch hydraulic system.