Adjusting the bearing clearance of the rear hub of the GAZ-2705

To adjust the bearings you need:

- lift the wheels with a jack so that the tires do not touch the support plane.

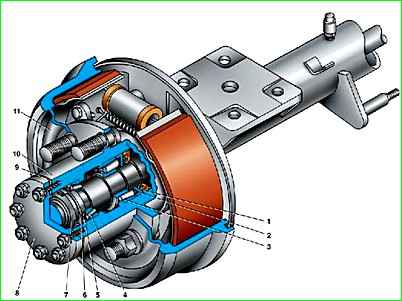

Unscrew the nuts and remove the axle shaft 8, unscrew the lock nut 7, remove the lock washer 6, loosen the bearing mounting nut 5 by ⅓-½ turn, check the ease of rotation of the wheel.

If the wheel is braking, eliminate the cause of its tight rotation (touching the drum and brake pads) and only then make adjustments;

- tighten nut 5 securing the bearings with a special wrench with a wrench (600 mm) to a torque of 70 to 100 Nm (7-10 kgm).

When tightening the nut, it is necessary to rotate the wheels to evenly place the rollers in the bearings;

- unscrew nut 5 to an angle of 22-45° (1-2 slots, no more, on lock washer 6).

Install the lock washer and make sure that the lock pin fits into the slot in the washer;

- - tighten locknut 7 to a torque of 150-200 Nm (15-20 kgm);

- - check the adjustment. When adjusted correctly, the wheel should rotate freely and there should be no axial play;

- - insert axle shaft 8, install spring washers and tighten the nuts of the axle shaft studs.

Lower the wheel;

. check the adjustment of the bearings according to the degree of heating of the wheel hub during a test run of 8-10 km.

Strong heating of the hub (over 70° C, the hand cannot tolerate it) is unacceptable and must be eliminated by repeated adjustment.

The rear wheel hub bearings are lubricated with oil coming from the rear axle housing through the axle housings.

Therefore, after adjusting the bearings, you should check the oil level in the rear axle housing and add oil if necessary.

To fill the hub cavity with lubricant, lift the right and left wheels alternately to a height of at least 300 mm and hold for at least 6 minutes. at an oil and ambient air temperature of at least 15° C.

Removing the hub

Hubs are removed from the vehicle only when replacing worn bearings or oil seals. for this you need:

- - loosen the wheel nuts, and then lift the wheels with a jack so that they do not touch the support plane, then remove the wheels;

- - unscrew the nuts and remove the axle shaft

- - unscrew the nut, remove the lock washer, unscrew the hub fastening nut.

Remove the hub with the drum, bearings and oil seal;

- replace damaged parts. When replacing the oil seal, it is necessary to press it evenly.

After pressing the oil seal, its back side should be in the same plane with the end of the hub.

After replacing damaged parts, it is necessary to adjust the bearings as indicated above.