Replacing wheel bearings and axle cuffs

Release the handbrake by placing stops under the front wheels

Remove the rear wheels on one side of the car (see How to remove the rear wheels and axle shafts of a Gazelle car).

Take out the axle shaft.

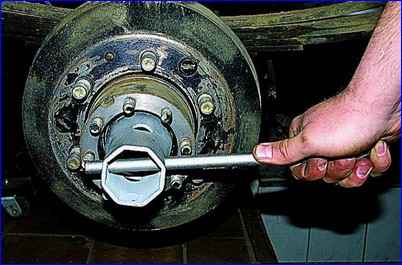

Use a special wrench from the standard “62” set to unscrew the lock nut.

Remove the locknut from the hub.

Remove the lock washer by prying it with a hook or thin pliers.

Use the same head to unscrew the bearing nut and remove it.

Please note that it is installed with the pin facing out.

Pulling towards you, remove the hub along with the brake drum, bearings and cuff from the axle housing.

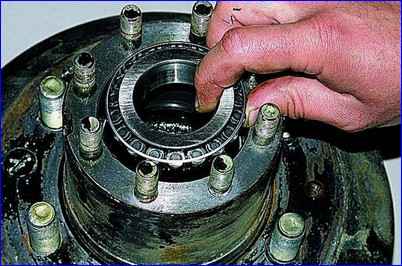

Take out the inner ring of the outer bearing with the rollers.

Use a screwdriver to remove the cuff

Take out the thrust washer

Take out the inner ring of another bearing with rollers

Use a soft metal drift to knock out the outer rings of the outer and inner bearings

Take out the outer rings

We wash the inner cavity of the hub and other parts with kerosene or diesel fuel.

Lubricate the bearing seats with transmission oil.

Use a hammer to press the outer rings of the new bearings through the soft spacer.

Lubricate with Litol-24 ro face and separator of the inner bearing and insert its inner ring into the outer one.

Having installed the thrust washer and lubricated the edges of the new cuff with Litol-24, using the old cuff as a mandrel, we press in the new cuff.

We put the hub on the axle housing, after which we install the inner ring with the outer bearing rollers lubricated with Litol-24.

Tighten the adjusting nut and adjust the bearings.

Install the axle shaft, and then fill the wheel hub with oil (see How to change the oil in the rear axle gearbox of a gazelle).

Adjusting wheel bearings

Jack up the rear axle of the car until the wheels lift off the ground.

Remove the wheels.

Remove the axle shaft.

Unscrew the outer nut, remove the lock washer and loosen the bearing nut ⅓ turn.

Check the ease of rotation of the hub.

If the brake pads touch the drums, we eliminate this malfunction, and then repeat the adjustment.

Tighten the bearing nut with a special head from the standard set to a torque of 7–10 kgf.m, constantly rotating the hub to self-install the rollers in the bearings.

Unscrew the bearing nut to an angle of 22–45° (1–2 slots on the lock washer, no more).

Install the lock washer so that the locking pin of the nut fits into its slot.

Install and tighten the outer nut with a torque of 15–20 kgf.m using the same head.

After this, the hub should rotate freely without play, clicks or jams.

Install the remaining parts in reverse order and fill the hub with oil (see How to change the oil in a gazelle rear axle gearbox).

We check the adjustment by driving the car for about 10 km. Heating the hub above 70° C (the hand cannot tolerate it) is considered unacceptable.

We repeat the adjustment, and then check the hub temperature again after the same mileage.