Replacement of chains and gears of the gas distribution mechanism ZMZ 406 GAZ-2705

You will need: a 6-point hex key, 12-point, 13-point, 14-point sockets, a small chisel, a hammer

Drain the cooling system.

Remove the radiator of the cooling system, article - Radiator Gazelle

Remove the drive belt of the power steering pump and fan pulley, article - Removing the ZMZ 406 GAZ-2705 generator belt

Remove the alternator and water pump drive belt.

Loosen the supply hose clamp and remove the hose.

Remove the cylinder head cover.

Remove the four bolts and remove the front cylinder head cover assembly with the fan drive clutch and fan (the viscous clutch and fan have been removed for clarity).

Remove the water pump.

Remove the crankshaft speed sensor (timing sensor).

Remove the crankshaft pulley.

Remove the oil sump.

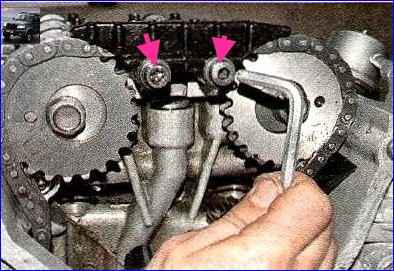

Remove the two bolts and remove the upper chain hydraulic tensioner cover with the gasket. Remove the cover carefully, as it is affected by the hydraulic tensioner spring.

Then remove the hydraulic tensioner.

Remove the lower chain hydraulic tensioner in the same way.

Remove the seven bolts and remove the chain cover.

Remove the cover carefully so as not to damage the front crankshaft oil seal installed in it, the cover gaskets and the cylinder head gasket.

Unscrew the bolt of the upper tensioner and remove the tensioner lever with the sprocket.

In the same way, remove the lower tensioner arm with the sprocket.

Unscrew the two bolts and remove the plastic chain guide.

Remove the gears from the camshafts by unscrewing the bolts securing the gears to the camshaft flanges.

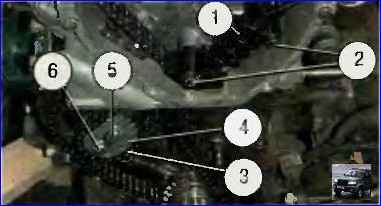

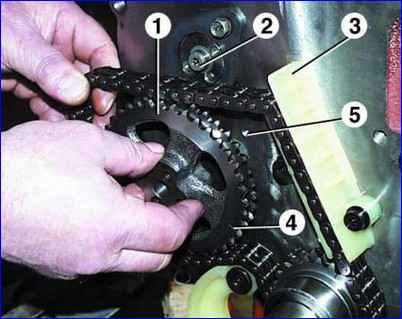

Unscrew the bolts 2 and lift up the chain guide 1.

Bend the ends of the locking plate 6 and remove the bolt 5, to do this, hold the intermediate shaft from turning by inserting a screwdriver into the hole of gear 3.

Remove gear 4 by inserting a screwdriver between it and gear 3 and pressing the screwdriver like a lever against gear 3.

Remove gear 4 from the upper chain and remove the chain by pulling it up.

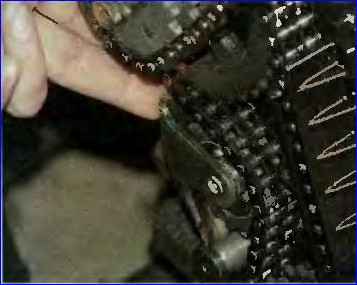

Remove gear 3 from the intermediate shaft and remove it from the lower chains. Remove the lower chain from the crankshaft gear.

If it is necessary to remove gear 2 from the crankshaft, first remove bushing 1 and the rubber O-ring between the bushing and the gear. Then compress gear 2 using a puller.

After removal, wash the chains and gears in gasoline, wipe and dry them.

Inspect the chains. If the chain bushings are cracked, chipped, or show significant wear, replace the chains.

Replace gears whose teeth are chipped or chipped.

Replace damaged chain guides.

The tensioner sprockets must rotate freely on the axles. If the sprocket teeth are chipped or chipped, replace the tensioners.

If you removed the gear from the crankshaft, press it onto the crankshaft, install the O-ring and bushing.

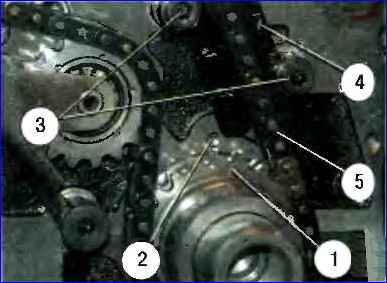

Rotate the crankshaft so that mark 1 on the crankshaft gear aligns with mark 2 on the cylinder block.

In this case, the piston of the 1st cylinder will take the TDC position.

Install chain guide 4 without tightening bolts 3 securing the guide.

Place chain 5 onto the crankshaft gear, having previously lubricated it with engine oil.

Place the chain on driven gear 1 and install the gear on the countershaft 2 so that the pinion pin fits into the hole in the countershaft.

In this case, mark 4 on the gear must coincide with mark 5 on the cylinder block, and the chain branch passing through damper 3 must be tensioned.

Install the countershaft drive gear so that its locating pin fits into the hole in the driven gear.

Screw in the two bolts securing the intermediate shaft gears, placing a locking plate under them.

Tighten the bolts to a torque of 22–25 Nm (2.2–2.5 kgf m) and secure them by bending the edges of the locking plate on the edge of the bolt heads.

Press the tensioner lever, tension the chain and check the alignment of the marks on the gears and the cylinder block.

Tighten the chain guide mounting bolts.

Lubricate the upper chain with engine oil and then slide it onto the countershaft drive gear through the hole in the cylinder head

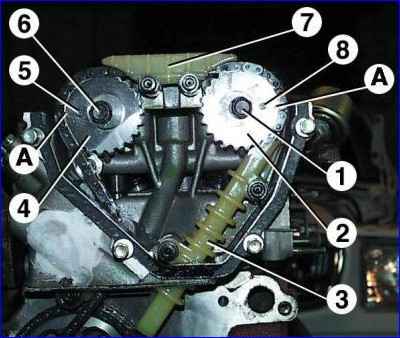

Put the chain on gear 2 and, turning the exhaust camshaft slightly clockwise, install gear 2 with the chain on it.

The camshaft pin 8 should fit into the gear hole.

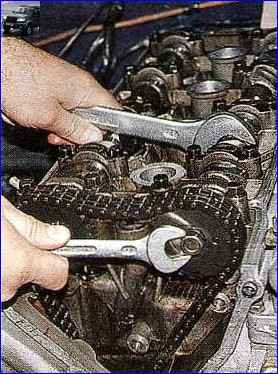

Screw in bolt 1. Turn the camshaft with a wrench using the square socket on the camshaft.

Then, slightly turn the camshaft counterclockwise to tighten the chain.

The intermediate and crankshafts should not turn. The “A” mark should align with the top surface of the cylinder head.

Unscrew bolt 6 and remove gear 4 from the intake camshaft.

Put the chain on gear 4 and install gear 4 with the chain on the camshaft, turning the camshaft slightly clockwise.

Pin 5 of the camshaft must fit into the gear hole.

Turn the chain by turning the camshaft slightly counterclockwise.

Mark “A” on gear 4 should align with the top surface of the cylinder head. The remaining shafts should not rotate.

Screw in bolt 6. Tighten bolts 1 and 6 to a torque of 46–74 Nm (4.6–7.4 kgf m), holding the camshafts from turning with a wrench using the squares.

Install damper 3 by pushing it into the hole in the block head. Install damper 7.

Install the chain cover and water pump. Apply a thin layer of sealant to the surfaces of the cover adjacent to the cylinder block and cylinder head.

When installing the chain cover, be careful not to damage the crankshaft oil seal about the shaft.

Install the hydraulic tensioners for the upper and lower chains. Install the crankshaft pulley.

Screw in the crankshaft pulley mounting bolt, then, engaging fifth gear and braking the car with the parking brake, tighten the bolt to a torque of 104–128 Nm (10.4–12.8 kgf m), holding the crankshaft from turning.

When the ratchet is tightened, the pulley is pressed onto the crankshaft.

Turn the crankshaft two turns using the ratchet and set the piston of the 1st cylinder to the TDC position (see operation 3). Check that the marks match.

Install the front cylinder head cover, first apply a layer of sealant to the surface of the cover adjacent to the cylinder head.

Tighten the cover mounting bolts to a torque of 12–18 Nm (1.2–1.8 kgf m).

Install the cylinder head cover.

Tighten the cover mounting bolts to a torque of 6.0–12 Nm (0.6–1.2 kgf m).

Connect the hose and crankcase ventilation tube to the fittings on the valve cover, and the wires to the ignition coils.

Place the ends of the high-voltage wires onto the spark plugs.

Install the previously removed attachments.