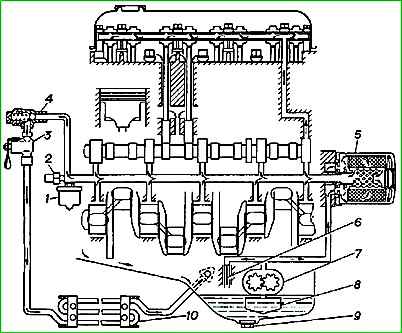

Engine lubrication system - combined: under pressure and splash

The lubrication system diagram is shown in the figure

Oil is sucked through the oil receiver by the oil pump and fed into the oil line through a full-flow filter.

The pump is equipped with a pressure reducing valve that bypasses the oil into the line, bypassing the filter element if its resistance is too high (clogged, starting a cold engine).

The bypass valve opens when the pressure difference at the inlet and outlet of the filter is 58-73 kPa (06-075 kgf/cm 2).

Oil filter* is installed on the cylinder block on the right side of the engine.

The filter is removed by rotating it counterclockwise.

When installing a new filter on the engine, you need to make sure that the sealing rubber gasket is in good condition, lubricate it with engine oil and screw the filter until the gasket touches the plane on the cylinder block, then tighten the filter by hand 3/4 of a turn.

The pressure in the engine oil system at an oil temperature of plus 80° C with the oil cooler turned off should not be less than 125 kPa (1.3 kgf/cm 2) at a crankshaft speed of 700 min 1 and 340 kPa (3.4 kgf/cm 2) - at a crankshaft speed of 2000 min 1.

When the oil cooler is turned on and the oil temperature is the same, the pressure should not be less than 78 kPa (0.8 kgf/cm 2) at 700 min 1 and 245 kPa ( 2.5 kgf/cm 2) at 2000 min 1.

Lubricating system maintenance

Maintain the oil level in the engine crankcase at the “P” mark on the oil level indicator.

Measure the oil level after 2-3 minutes. after stopping the warm engine.

Pour oil into the engine crankcase and change it in strict accordance with the specifications.

When operating the engine in a vehicle, monitor the operation of the oil pressure sensors.

The emergency oil pressure sensor is triggered at a pressure of 39-78 kPa (0.4-0.8 kgf/cm 2).

On a warm engine with a working lubrication system in idle mode, the warning light may light up, but should immediately go out when the crankshaft speed increases.

It is recommended to flush the engine lubrication system after two oil changes, to do this, drain the used oil from the crankcase of a hot engine, fill in special VNIINP-Fd washing oil 3-5 mm above the “0” mark on the oil level indicator and let the engine run for 10 minutes, at minimum crankshaft speed in idle mode.

Then drain the washing oil, replace the oil filter and fill with fresh engine oil.