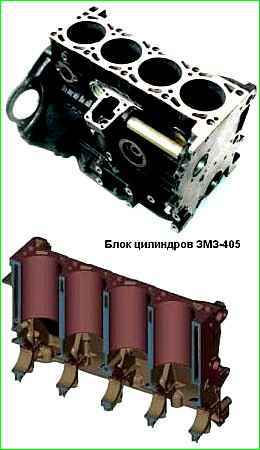

Defection and repair of the ZMZ-405 GAZ-2705 cylinder block

To determine the technical condition and repair of the cylinder block, remove the engine from the car and disassemble it

Remove the cylinder head (see “Replacing the cylinder head gasket”), the crankshaft (see “Removing, repairing and installing the crankshaft”), the connecting rod and piston group (see “Removing, repairing and installing the connecting rod piston group"), oil sump and oil pump (see "Removal, repair and installation of the oil pump"), as well as all attachments.

Inspect the cylinder block. If cracks are found, replace it.

Check the tightness of the cooling jacket of the block using the pressure test method: plug all holes in the block with wooden plugs, except one, to which connect the compressed air supply hose (You can also use rubber and plastic plugs of a suitable size).

Dip the block into a bath of water and apply compressed air at a pressure of 1.5 atm.

In places where the seal is broken, air bubbles will escape.

If a leak is detected, replace the unit.

In the same way, check the tightness of the oil passages of the block.

Inspect the cylinders.

If there are scuffs and other defects on the cylinder bore, bore the cylinders to the repair size and hone them.

Spare parts include pistons and piston rings of appropriate repair sizes.

All cylinders must be bored to the repair size, even if defects are found in only one.

Check the clearances between the cylinders and pistons.

The nominal gap is 0.024-0.048 mm, the maximum permissible is 0.25 mm.

Cylinders and pistons are divided by diameter into five size groups: A, B, C, D, E. The letter indicating the cylinder group is painted on the left outer side of the block opposite each cylinder.

The gap can be determined by measuring the diameters of the piston and cylinder. The piston diameter is measured in a plane perpendicular to the piston pin axis, at a distance of 8.0 mm below the piston pin axis. The diameter of the cylinder is measured in at least three zones within 15-100 mm from the top surface of the block (in two mutually perpendicular directions).

Also look at the article - “Repair of the ZMZ-405 cylinder block”