Basic instructions for replacing piston rings D-245E3

Remove the cylinder head and oil pan from the diesel engine.

Lower the piston to the bottom dead center by manually turning the diesel flywheel.

Clean the upper belt of the liner from carbon deposits, while preventing carbon particles from getting into the cylinder.

Do not use a steel scraper when cleaning in order to avoid damaging the "mirror" of the liner.

Unscrew the connecting rod cap fastening nuts, remove the connecting rod cap and remove the piston with the connecting rod from the cylinder.

Pull the piston with the connecting rod upwards - towards the cylinder head.

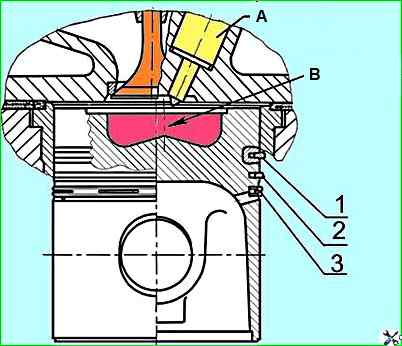

In accordance with Figure 1, an upper trapezoidal compression ring, one conical compression ring and one box-type oil scraper ring with a spring expander are installed on each diesel piston.

The compression rings on the end surface at the lock have the marking "top" or "TOP", which should face the piston bottom when installing the rings.

The joint of the oil scraper ring expander should not coincide with the ring lock.

Place the piston ring locks at an equal distance around the circumference.

Insert the piston with the connecting rod into the cylinder, install the connecting rod cap.

To avoid breakage of piston rings when installing the piston with the connecting rod into the cylinder, use a mandrel for crimping the rings.