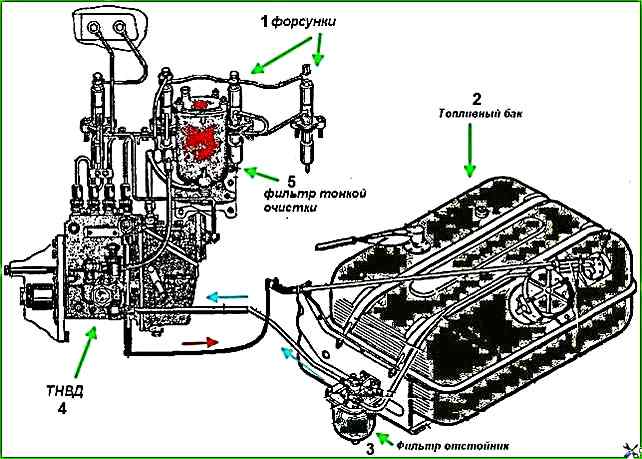

The fuel system consists of:

- - fuel tank;

- - coarse filter;

- - fine fuel filter;

- - booster pump;

- - high-pressure fuel pump;

- - injectors.

Fuel from the tank, having passed the coarse fuel filter, is supplied under a pressure of 0.8-0.9 MPa by the fuel pump to the inlet fitting of the high-pressure fuel pump.

Under the influence of the created pumping pressure, the safety valve opens access for fuel through the supply channel to the above-plunger spaces.

The incoming cam of the rotor moves the plunger upward, while the inlet opening of the intake channel is blocked and with further rise of the plunger, the fuel is compressed in the above-plunger space of the high-pressure fuel pump.

Compressed fuel enters the corresponding injector in accordance with the diesel stroke.

Excess fuel flows back to the tank.

Possible malfunctions D-245

Symptom of malfunction, cause of malfunction (Remedy)

Diesel engine does not develop full power:

- Incorrectly set fuel injection advance angle (knocking or smoking)

Adjust fuel injection advance angle

- Incorrect adjustment or clogged injector

Adjust injector on a special stand, wash and clean it if necessary

- Malfunction of fuel injection pump

Remove fuel injection pump from diesel engine and send for repair

- Insufficient fuel supply

Clean system

Check regulator lever drive and fix malfunction

Replace fine filter element

Purge system

Find the cause of the leak, fix it and bleed the system with a fuel pump

- Boost pressure has dropped

Clean the air cleaner

Replace the turbocharger

The diesel smokes in all operating modes:

- white smoke (indicates the presence of water or fuel vapor in the exhaust gases):

- - Poor tightness of the valve timing;

- - Wear of the liners and piston rings (accompanied by increased smoking and consumption of crankcase gases)

Send the diesel for repair

- Diesel is overcooled

Warm up the diesel

Maintain the coolant temperature during operation 75-95˚С

- Fuel injection advance angle adjustment is incorrect

Check and adjust the fuel injection advance angle setting

- Valve and rocker arm clearance adjustment is incorrect

Adjust valve and rocker arm clearances

- Coolant entering the fuel

Change the fuel, drain the sediment from the fuel filter

Bluish smoke (indicates increased oil entering the combustion chamber):

- Excess oil in the diesel crankcase

Drain the oil to the upper mark of the oil dipstick

- - Oil leak through the turbocharger seals

- - Wear of the valve stem seals valve timing

Replace valve stem seals

- - Clogged air cleaner

- - Reduced boost pressure

Replace turbocharger

Clean air cleaner

- Wear of cylinder-piston group parts

Injector malfunction:

- - stuck injector nozzle needle;

- - other models of nozzles are installed;

- - detached nozzle tip;

Black smoke (indicates incomplete combustion of fuel):

- - Clogged air cleaner

- - Leaky fuel system, air

- - Clogged exhaust system

- - Injection pump drive adjustment is broken

- Send diesel for repair

- Check and adjust injectors on the bench

- Identify faulty injector, flush or replace nozzle, adjust injector

- Install nozzles mod145.1112110

- Replace nozzle, adjust injectors on the bench

Increased fuel consumption

diesel does not reach idle speed

- - wear of nozzle holes;

- - increased fuel injection start pressure injector

Faulty fuel injection pump:

- - incorrectly adjusted regulator corrector and corrector for fuel injection pump boost;

- - excessive cyclic fuel supply;

- - incorrect fuel injection pump adjustment

- - Fuel injection pump faulty;

- - leaky pressure section of fuel injection pump;

- - excessive rotation speed of camshaft of fuel injection pump, corresponding

- - wear of the speed regulator weight bushings

- - wear of the guide bushing-fuel priming pump rod pair

- Adjust the cyclic feed with the nominal feed bolt

- Remove the fuel injection pump from the diesel engine and send it for repair

- Replace the guide bushing-rod pair, check the tightness and performance of the fuel injection pump

- Set the recommended fuel injection advance angle

- Adjust the clearances between the valves and rocker arms

- Adjust the fuel injection pump drive

- Remove the fuel injection pump from the diesel engine and send it for repair

Knocking during diesel engine operation

- The angle is set incorrectly fuel injection advance

- Check the fuel injection advance angle adjustment, play in the fuel injection pump drive

- Valve and rocker arm clearance adjustment is impaired

- The fuel injection pump fuel supply control lever does not reach the maximum frequency position when the fuel supply pedal is fully depressed

Fuel injection pump malfunction:

- - plunger sticking;

- - regulator malfunction

- Violation of clearances between rocker arms and valves

- Breakage of valve springs

- Valve stem sticking in the guide sleeve

- Worn pistons and surfaces of holes for piston pins.

- Worn bushings in upper heads connecting rods and in piston bosses

- Worn connecting rod and main bearings, scoring of cylinder liners

- Late fuel injection into unheated diesel cylinders (mild knocking and white smoke)

- Early fuel injection into diesel cylinders (strong knocking and black smoke)

Check and adjust clearances

Replace springs, eliminate jamming

Eliminate jamming; if this cannot be done, send the diesel engine for repair.

Submit the diesel engine for repair, replace worn or faulty parts with new ones during the repair process

Remove the high-pressure fuel pump from the diesel engine and send it for repair (check the condition of the pusher springs in the high-pressure fuel pump sections, adjust the cyclic feeds of the high-pressure fuel pump sections)

Check the injector and adjust it on the stand (check the position of the needles in the injectors)

The diesel engine is overheating

- High-pressure fuel pump malfunction: uneven distribution of injected fuel across individual cylinders of the diesel engine (knocking in individual cylinders)

Remove the high-pressure fuel pump from the diesel engine and send it for repair

- - Injector malfunction:

- - lack of clear fuel cutoff by the injectors;

- - clogging of the fuel injector drain line (loud knocking)

Adjust the injector on the stand

Break or strong stretching of the liquid pump drive belts

Check and adjust the belt tension; if necessary, replace the belts with new ones as a set, add coolant to the cooling system

Low coolant level

- Thermostat is faulty

Replace the thermostat

- Contamination of the outer surface of the radiator

Clean the radiator

- Contamination of the cooling system

Flush the cooling system

Clean and blow out the fuel lines

No oil pressure

The oil pressure on a warmed-up diesel engine is below the permissible limit, the oil pressure on a warmed-up diesel engine is above the permissible limit. Water in the lubrication system

- Oil pressure sensor or indicator is faulty (alarm does not work)

Replace the oil pressure sensor or indicator

- - Lubrication system pump drive faulty

- - Oil pressure sensor or indicator is faulty (alarm does not work)

Replace the oil pressure sensor or indicator

- Diesel crankcase filled with oil that does not meet the requirements of the operating manual

Change the oil in accordance with the operating manual

- Oil level in the crankcase is below the permissible level

Add oil to the required level

- Oil dilution by fuel, coolant or due to overheating

Eliminate the cause of oil dilution, change the oil

- Seized or incorrectly adjusted oil drain valve

Adjust or replace the valve.

- Oil pump malfunction

Send the diesel engine for repair

- Oil line connections are leaky

Identify the leaky location and restore it

- Wear of main and connecting rod journals and crankshaft liners

Send the diesel engine for repair

- High-viscosity oil is poured into the diesel crankcase

Change the oil in accordance with the lubrication chart

- Clogged or faulty safety valves

Check the valves, replace the valves if necessary

- Leakage along the rubber rings of the cylinder liners

Replace faulty seals rings

Send the diesel for repair

- Weak tightening of the cylinder head mounting bolts

Tighten the bolts

The diesel does not starts or starts poorly:

Starter failure or decreased crankshaft speed

Check the state of charge of the batteries.

No fuel supply:

- - thickening of fuel in the fuel lines

- - clogged fuel lines or fuel tank intake

- - freezing of water in the fuel lines, in the fuel filter cap or fuel tank intake screen

- - no fuel supply to the high-pressure fuel pump

- - air in the fuel system

- - high-pressure fuel pump malfunction

- - incorrect adjustment of the fuel injection advance angle

Fuel system leak

Malfunction Fuel injection pump:

- - uneven fuel supply by sections;

- - plunger sticking;

- - rack sticking;

- - delivery valve malfunction;

- - tappet spring breakage

- - speed controller malfunction

Low crankshaft speed

Unsatisfactory operation of individual injectors:

- - injector nozzle needle stuck;

- - other models of injectors installed;

- - nozzle tip torn off;

- - nozzle holes worn;

- - reduced fuel injection start pressure of injectors.

- Check the connections on the batteries and clean the contacts if necessary.

- Check that the oil and fuel are suitable for the season, bleed the fuel supply system.

- If necessary, dilute the fuel with kerosene depending on the ambient temperature in a ratio of up to 1:1 in accordance with the operating manual.

- Flush the intake, blow out the fuel lines.

- Carefully warm up the fuel pipes, filters, FGO and tank by placing a rag around them and pouring hot water over them.

- Drain the water from the FGO, fuel tank and bleed the system with a fuel priming pump.

- Check the tightness of the low-pressure fuel lines.

- Drain the sediment from the FGO and FTO filters.

- Flush or replace the FTO filter elements, clean the reflector with a mesh and blow it out with compressed air.