We carry out the work on an inspection pit or lift. We hang up and remove the front wheels

We remove the mudguards and the protective plate of the engine oil pan.

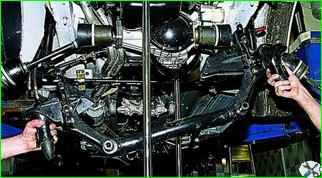

We remove the upper and lower suspension arms.

We remove the steering knuckles complete with upper and lower ball joints, wheel hubs, and front brakes.

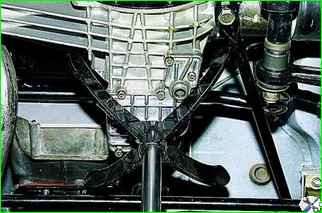

We unscrew the nuts securing the rubber-metal mounts of the powertrain suspension from the crossmember brackets.

Installing a support under the front axle gearbox housing

Installing a support under the generator bracket.

Using a 19 mm open-end wrench, unscrew the two nuts of the bolts securing the right rebound buffer bracket to the cross member.

Hold the bolts from turning with a head of the same size.

We take out the bolts.

With the head "on 17" unscrew the nut securing the rebound buffer bracket to the upper spring support

Remove the bracket

Similarly, remove the left rebound buffer bracket, only take out the bracket mounting bolts towards the engine compartment

Using a 19 mm open-end wrench, unscrew the two nuts securing the cross member to the right side member and the two nuts securing it to the left side member.

Removing the cross member.

The nuts of the bolts securing the upper spring support to the crossmember are secured with welding.

If it is necessary to separate the crossmember and the upper spring support, cut off the nuts.

We measure the distance between the outer surfaces of the upper arm mounting brackets.

For a serviceable crossmember, this distance is 736±1.5 mm

If the cross member is significantly deformed, when it is impossible to adjust the front wheel alignment angles with washers while all other suspension elements are in satisfactory condition, replace the cross member.