Removing the gearbox (article – “Removing the gearbox”)

In order for the clutch housing mounting bolts to be easily removed, tap their heads with a copper hammer.

Screw the clutch housing mounting bolt into the hole in the engine cylinder block.

In order to keep the flywheel from turning, we lean the mounting blade on the bolt and insert its end between the teeth of the flywheel ring.

Using a 13mm socket, unscrew the six bolts securing the clutch housing to the flywheel.

We unscrew the bolts evenly, no more than one turn each, so as not to deform the clutch casing.

Remove the driven and driven clutch discs.

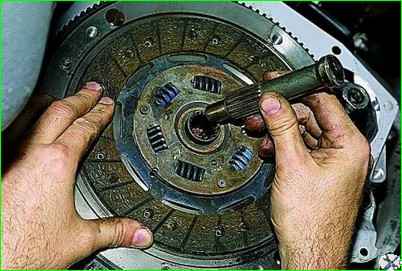

When installing the clutch, we orient the driven disk with its protruding part towards the drive disk, and insert the centering mandrel into the hole in the hub.

Insert the mandrel into the hole in the inner ring of the crankshaft bearing and secure the clutch drive disc in this position, evenly (one revolution per pass) tightening the bolts to the required torque.

Remove the centering mandrel from the hole.

Clutch fastener tightening torques:

- - bolt securing the clutch pressure plate to the flywheel M8 - 19.1-30.91 Nm (1.95-3.15 kgf m);

- - nut of the bolt-axis securing the clutch and brake pedals to the bracket M12x1.25 - 58.3-72.0 Nm (5.95-7.35 kgf m);

- - bolt securing the clutch slave cylinder to the clutch housing M8 - 15.0-18.6 Nm (1.53-1.9 kgf m).