We check the belt tension by its deflection between the pulleys of the units

With normal belt tension, its deflection under a force of 98N (10 kgf) should be 10–15 mm between the pump pulleys and the generator or 12–17 mm between the pump pulleys and the crankshaft.

We adjust the belt tension by moving the generator (with the nuts of its fastening loosened): from the engine to increase the tension or to the engine to decrease the tension.

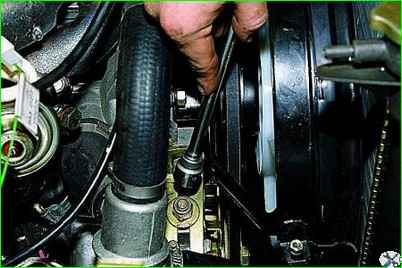

To replace the belt, loosen the nut securing the generator to the tension bar with a “17” socket on a carburetor engine or a “13” socket on an injection engine

We move the generator towards the cylinder block to loosen the belt tension.

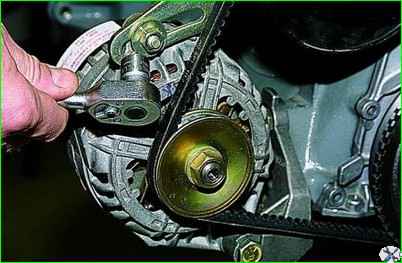

We move the generator, acting on it with a screwdriver as a lever in the slot of the tension bar: on a carburetor engine;

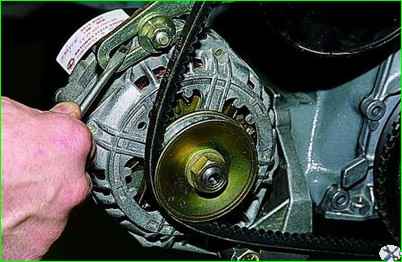

on an injection engine.

On engine 21214, remove the crankshaft position sensor.

Remove the belt.

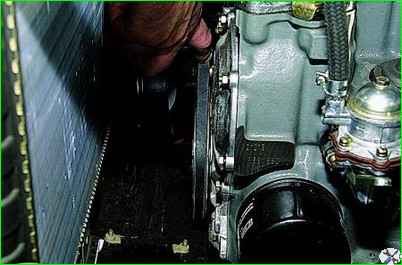

On a carburetor engine it has to be removed through the gap between the radiator and the casing

Install the belt in reverse order.

Rotate the crankshaft clockwise two turns and check the belt tension.

Excessive belt tension causes increased loads on the generator and pump bearings.