Remove the cardan shaft (see the article - "Removing cardan shafts")

Using round-nose pliers, remove the four retaining rings.

Mark the hinge parts so that they are placed in the same position during assembly.

We apply marks with quick-drying paint so as not to mix up the position of the hinge forks during assembly.

You can apply marks with a chisel

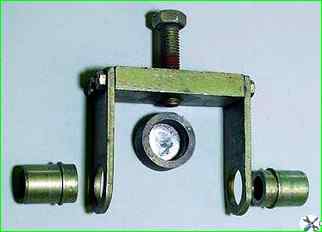

We install a special puller on the hinge flange fork and press the bearing housing out of the fork socket until the crosspiece stops in the fork.

If there is no puller, then we rest the cardan flange fork on the support (vice jaws), and through a suitable section of pipe we strike the cardan shaft fork with a hammer, moving it down until it stops against the crosspiece.

In the same way, we press out the bearing housing located on the opposite side of the cardan fork.

Having rested the cardan shaft fork on the vice jaws, we press out the bearing housings from the sockets one by one.

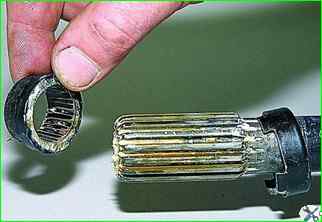

When pressing out the bearing housings, they do not come out of the fork holes completely, therefore, even if you move the crosspiece all the way to the fork, the crosspiece pin is not removed from the bearing housing.

To finally press out the bearing housing, you need to clamp the bearing housing in a vice so that it does not turn in the jaws of the vice and grind chamfers on the bearing housing with a grinder.

Clamp the bearing housing by the chamfers made and, turning the cardan shaft around the bearing axis, remove the fork from the bearing housing.

Remove the flange with the crosspiece. The housing of one crosspiece bearing, we also press it out with a grinder

We take out the crosspiece

Having clamped the cardan shaft fork in a vice, we knock out the housing of the other bearing, which remains in the fork, with a punch. Similarly, knock out the bearing housing remaining in the flange.

Before installing a new crosspiece, make sure there is grease in the bearings - 0.8-1.2 g of Fiol-2U grease is placed in each bearing.

Put the seals on the crosspiece tenons and insert the crosspiece into the sockets of the cardan shaft fork.

In a vice with jaw pads made of soft metal, we press the bearing into the fork socket until its end rests against the jaw of the vice.

When this om insert the crosspiece tenon into the bearing seat so that the bearing needles do not fall out.

During the pressing process, by rocking, check the ease of rotation of the crosspiece in the bearing.

Using a suitable head or a piece of pipe, press the bearing into the fork seat deeper than the groove for the retaining ring.

Using round-nose pliers, install the retaining ring into the groove.

Also press the bearing into the other socket of the shaft fork until the opposite bearing stops at the end of the retaining ring and install the second retaining ring.

Orienting the flange according to the marks relative to the cardan shaft fork, insert the crosspiece pins into the flange sockets.

Alternately press two bearings into the flange seats and install retaining rings in its grooves

After assembling the cardan joint, you need to tap the fork and flange with a hammer with a plastic striker in order to select the gaps between the ends of the bearing housings and retaining rings (for selection of the thickness of retaining rings, see the article - "Features of cardan shafts").

Checking the ease crankshaft joint rotation.

Replacing the cardan shaft sliding fork seal

Remove the cardan shaft according to the article - "Removing and installing cardan shafts"

Using a suitable punch or screwdriver, move the seal cage along the shaft

We make marks of the shaft and yoke locations to install them in the same way, otherwise an imbalance may occur

We separate the shaft and fork

Pull the seal out of the shaft

Remove the collar

We assemble the unit in the reverse order.

We put the collar and a new oil seal (with the large outer diameter towards the fork) on the shaft.

We lubricate the splined connection of the shaft with Fiol-2U grease.

When connecting the shaft and the fork, we align marks.

Press the oil seal with the collar until it stops against the end of the fork and squeeze the collar onto the fork groove.

Features of cardan transmission repair, on cars manufactured before 1988

The cardan transmission is repaired using the same methods and in the same sequence as described above, but taking into account the following:

- - the crosspiece bearings are pressed out of the cardan joint forks with clamp 67.7823.3522 or knocked out with a hammer through a punch;

- - the crosspiece bearing retaining rings have the following dimensions and colors: 1.50 - unpainted; 1.53 - dark brown; 1.56 - blue; 1.59 — black and 1.62 — yellow.

Therefore, during assembly, a gauge with petals of the specified thickness is used.