The car is equipped with two braking systems: working and parking

In the event of damage to the working system, the vehicle is stopped by a serviceable part (the brake drive circuit of the front or rear wheel brakes) of the working brake system

Each brake system consists of brake brake mechanisms and a brake drive.

The service brake system acts on all wheels of the car and is driven by the pedal when you press it with your foot.

The service braking system includes front and rear brake mechanisms and a hydraulic dual-circuit drive: primary (front brakes) and secondary (rear brakes).

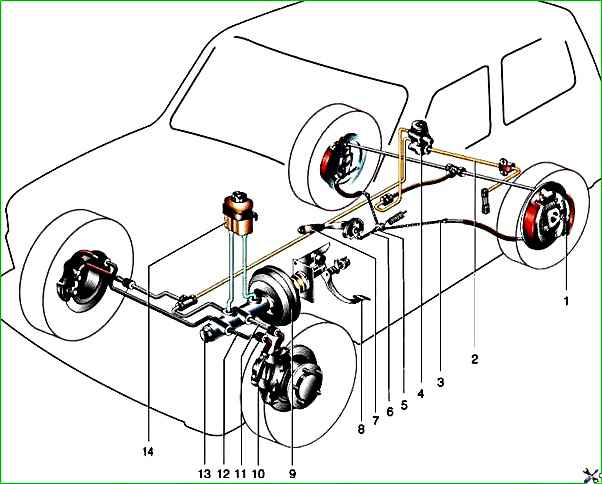

VAZ-2121 brake system diagram: 1 - rear wheel brake mechanism; 2 - pressure regulator drive lever; 3 - rear parking brake cable; 4 - pressure regulator; 5 - rear cable guide; 6 - front parking brake cable; 7 - parking brake lever; 8 - brake pedal; 9 - vacuum booster; 10 - front wheel brake mechanism; 11 - front and rear brake circuit pipeline; 12 - front brake circuit pipeline; 13 - main cylinder; 14 - master cylinder reservoir

Front disc brakes. They are located in the front wheels of the car.

The rotating and rubbing parts of the brake mechanisms are brake discs.

The cast iron brake disc is pinned to the front wheel hub.

From the front side, in the direction of travel of the car, the brake disc is covered by a caliper, which is a U-shaped bracket with guide bevels, which are sandwiched between the brake pad guide and the clamping arms, which also have guide bevels.

This type of fastening of the caliper ensures that when braking, it moves along the guide bevels of the levers and the guide.

The caliper has a protective casing.

The guide attached to the steering knuckle contains brake pads with friction linings.

Using axles, two caliper clamping arms are pivotally connected to the brake pad guide.

The brake cylinder block is pressed into the brake caliper.

The block has three cylinders, of which the middle and lower ones are interconnected by a channel and connected to the front brake drive circuits, and the top cylinder is connected to the rear brake drive circuit.

Each cylinder has a piston and a rubber sealing ring in the cylinder groove.

This ring not only seals the piston in the cylinder, but also, due to its elasticity, ensures that the piston is removed from the pad after braking.

Thus, rubber sealing rings ensure automatic adjustment of the gap between the brake disc and the brake pads.

The pistons of all cylinders are in contact with the internal brake pad and are covered with rubber protective caps on its side.

On the inside, the front brake mechanism is covered with a brake shield.

When braking, under the influence of fluid pressure in the hydraulic drive, the pistons move the inner brake pad relative to the guide and caliper and press it against the brake disc.

At the same time, under the influence of fluid pressure, the cylinder block moves along with the caliper along the bevels of the guide and clamping arms.

In this case, the caliper moves the outer brake pad relative to the guide and presses it against the brake disc.

Both brake pads are pressed against the brake disc with the same force, since the fluid pressure on the pistons and the bottom of the cylinder block is the same.

After braking stops, the fluid pressure on the pistons and the bottom of the cylinder block drops sharply.

Due to the elasticity of the rubber rings, the pistons are moved away from the inner brake pad, which at the same time moves away from the brake disc due to its runout.

At the same time, the outer brake pad, together with the caliper, also moves away from the brake disc as a result of its runout.

When the friction linings of the brake pads wear out, the gap between the linings and the brake disc increases.

When braking under the influence of fluid pressure, the pistons will move relative to the sealing rings and take a new position in the cylinders, which will compensate for the wear of the friction linings.

After braking stops, the brake pads will move away from the brake disc by the same amount, determined by the deformation of the rubber rings.

In this way, a constant gap between the brake pads and the disc is automatically maintained.

In this regard, during operation, the gap between the pads and the front brake disc does not require adjustment.

When braking, the brake pads act on a relatively small part of the torus surface brain disc, leaving most of it open, which is effectively blown with air.

The result is very rapid cooling of the brake disc, which ensures high braking efficiency even during frequent braking at high speeds.

The rear brakes are drum and shoe. They are located in the rear wheels of the car.

The rotating parts of the brake mechanisms are the brake drums, the rubbing parts are the brake pads, which, when braking, self-align relative to the brake drum, which ensures the greatest braking effect and more uniform wear of the friction linings.

The stamped steel brake shield is bolted to the rear axle beam flange.

In the lower part of the brake shield there is a support into which the lower ends of the brake pads with friction linings rest.

The upper ends of the pads are in contact with the pistons of the wheel brake cylinder.

The lower and upper ends of the brake pads are tightened by springs.

The lateral movement of the pads is limited by struts with springs that press the pads against the brake shield.

This type of fastening of the brake pads to the brake shield allows them to freely self-align relative to the brake drum during braking.

The brake pads with their ribs rest against the eccentrics mounted on the brake shield.

Using these eccentrics, the gap between the pads and the brake drum is adjusted.

The brake drum is bolted to the axle shaft flange.

When braking, under the influence of fluid pressure in the brake drive, the pistons of the wheel brake cylinder press the pads against the brake drum.

At the same time, the tension spring of the pads is stretched.

After braking stops, the fluid pressure on the pistons drops sharply, and under the action of the spring, the pads move away from the brake drum until they stop at the adjusting eccentrics.

The rear brake mechanisms, being elements of the service brake system, simultaneously perform the functions of the brake mechanisms of the parking brake system.

For this purpose, they are equipped with additional devices, which include: an expansion lever mounted on the axle, on the rear brake pad, and a spacer bar installed between the expansion lever and the front brake pad.

When using the parking brake system, the lower end of the release lever moves under the action of the cable to the front brake shoe.

In this case, the release lever, turning around its axis, first presses the front brake shoe to the brake drum, and then the rear one, through a spacer bar.

Possible brake malfunctions and methods for eliminating the brake system

Cause of malfunction - Elimination method

Creak, squeal when braking

Limited wear of the brake linings - Replace the brake pads (it’s better to have them all on one axis at the same time), article - “Replacing the front pads”, “How to replace the brake pads of the rear wheels”

Introduction of foreign particles (sand) into the lining material - As a rule, does not require intervention (the lining can be cleaned with a wire brush)

Poor quality of the lining material - Replace the pad (preferably all on the same axis at the same time)

Severe corrosion of the brake disc (due to poor quality material of the disc and/or lining) - Grind (grind) or replace the disc

The brake pad lining has peeled off from the base - Replace the pad (preferably all on one axis at the same time)

The tension spring of the rear brake pads is weakened or broken - Replace the spring

Braking with wheel locking - Do not over-braking, use tires appropriate for the driving conditions

Increased brake pedal travel (pedal is soft or sinks)

Air in the brake system, leakage of brake fluid through leaks in hydraulic drive connections, damage to the cuffs in the master brake cylinder, pressure regulator, damage to brake pipes and hoses - Inspect all lines, their threaded connections and cylinders, eliminate leaks.

Restore the normal fluid level in the brake reservoir and bleed the system, article - “How to bleed the brakes”

If you find damage to the brake hoses (cracks, swelling or traces of brake fluid), replace the hoses, article - “How to replace brake pipes and hoses”

If you suspect defects in the master brake cylinder, replace it with a known good one

The rubber cuffs of the cylinders are swollen due to oil, gasoline, etc. getting into the brake fluid. - Replace the cylinders, hoses, completely drain the brake fluid, flush the system with fresh fluid and bleed

Brake overheating - Allow the brakes to cool. Check the thickness of the linings and brake discs.

Use only brake fluids recommended by the manufacturer in the system. Replace brake fluid promptly

The gap between the pads and the drum has been increased m (the automatic slack adjustment device does not work) - Replace the wheel cylinder, bleed the system

Increased (more than 0.25 mm at the edge) runout of the brake disc - Replace the disc

One of the circuits of the service brake system is not working - Eliminate fluid leakage from the brake system, bleed the system

The brake pedal travel is within normal limits (the pedal is hard), but the car does not brake well

Oiling of brake discs, drums, linings - Clean oily discs and drums, replace pads (as a last resort, sand them down).

It is strictly forbidden to clean the pads with solvents! Eliminate the cause of the oiling (replace the axle shaft seal)

An ice or salt crust has formed on the surface of the linings (in winter); the linings are wet - When starting to drive, at low speed, check the brakes. In the rain and after driving through deep puddles, dry the brakes by lightly pressing the pedal

Poor quality of the lining material - Replace the pads (preferably all on the same axis at the same time)

Clogged brake lines: tubes (due to dents) or hoses (due to swelling or delamination of rubber) - Replace damaged tubes and hoses

Piston jamming in the cylinder, pads in the caliper - Replace the cylinder, clean the contacting surfaces of the pads and caliper, lubricate them with CV joint-4 before installation

Complete wear of the brake linings (brake grinding) - Replace the brake pads (preferably all on one axis at the same time)

The brake pad lining has peeled off from the base - Replace the pad (preferably all on one axis at the same time)

The pressure regulator drive is incorrectly adjusted - Adjust the drive

The pressure regulator is faulty - Replace the regulator

The vacuum booster is faulty or the hose connecting the booster to the inlet pipe is leaking - Check the integrity of the hose, its fit on the fittings, and the tightness of the clamps.

To check the amplifier, turn off the engine, press the brake pedal 5–8 times and, while holding the pedal pressed, start the engine.

If the amplifier is working properly, after starting the engine the pedal should noticeably “move” forward. Replace faulty amplifier

Incomplete release of the brakes on all wheels

Incorrect position of the adjusting bolt relative to the cover of the vacuum booster - The end of the bolt should protrude relative to the end of the cover by 1.25–0.2 mm

The rubber cuffs of the cylinders are swollen due to oil, gasoline, etc. getting into the brake fluid. - Replace the cylinders, hoses, completely drain the brake fluid, flush the system with fresh fluid and bleed

Main cylinder piston jamming (due to corrosion, broken return springs, mechanical impurities entering the fluid) - Replace the master cylinder, bleed the system

Brake pedal sticking: the return spring is broken or stretched, the pedal bushings are heavily worn, not lubricated, axle corrosion - Replace the defective spring, bushings, put fresh Litol-24 lubricant in them

Slowing down one of the wheels when the brake pedal is released

Wheel cylinder piston jammed - Replace cylinder

The rubber cuffs of the cylinders are swollen due to oil, gasoline, etc. getting into the brake fluid. - Replace the cylinders, hoses, completely drain the brake fluid, flush the system with fresh fluid and bleed

Clogged brake lines: tubes (due to dents) or hoses (due to swelling or delamination of rubber) - Replace damaged tubes and hoses

Detachment of the rear brake pad lining - Replace the pad (preferably all on one axis at the same time)

The tension spring of the rear brake pads is weakened or broken - Replace the spring

Deformation of the spacer bar, misalignment of the pads due to deformation of the brake shields - Straighten or replace the spacer bar, brake shields

The parking brake is too tight, the cables are jammed in the sheaths - Adjust the tension of the cables, lubricate them with engine oil, if the sheath is damaged or the cable wires are frayed, as well as if there is severe corrosion, replace them

The parking brake does not hold well

Incorrect drive adjustment - Adjust drive

The drive cables are stuck in the sheaths - Lubricate the cables with engine oil, if the sheath is damaged or the cable wires are frayed, as well as if there is severe corrosion, replace them

The brake drums and linings are oily - Clean the oily drums, replace the pads (in extreme cases, sand them down).

It is strictly forbidden to clean the pads with solvents! Eliminate the cause of the oiling (replace the axle shaft seal)

An ice or salt crust has formed on the surface of the linings (in winter); the linings are wet - When starting to drive, at low speed, check the brakes. In the rain and after driving through deep puddles, dry the brakes by lightly pressing the brake pedal

Complete wear of the brake linings (brake grinding) - Replace the brake pads (preferably all on one axis at the same time)

When released the parking brake lever does not release the wheels

After the car has been parked for a long time, the pads are stuck (or frozen) to the drum - While pulling the parking brake lever or cables, try to carefully (so as not to tear off the brake linings) turn the wheel.

Check the ease of movement of the cables in the shells, the pistons in the wheel cylinders, the rigidity of the return springs of the cables and the tension springs of the pads.

When parking the car, if possible, do not tighten the brake, but engage the gear

Incorrect drive adjustment - Adjust drive

The drive cables are stuck in the sheaths - Lubricate the cables with engine oil, if the sheath is damaged or the cable wires are frayed, as well as if there is severe corrosion, replace them

Driving the vehicle away from straight-line motion (on a flat road)

Different tire pressure - Set normal tire pressure

Violation of the longitudinal inclination of the steering axis and/or camber of the front wheels - Adjust the angles of inclination of the steering axis and/or camber of the front wheels

Significant difference in tire wear - Replace worn tire

Uneven settlement or broken suspension springs - Replace both springs

Vehicle suspension and/or body parts are deformed - Straighten or replace deformed parts and body panels

Displacement of the rear axle due to breakage of the rods or their mounting brackets - Replace the rods, weld the brackets

Wheel braking due to jamming of the wheel cylinder piston - Replace the cylinder

Rear wheel braking due to weakening or breakage of the rear brake pad tension spring - Replace the spring

Clogged brake lines: tubes (due to dents) or hoses (due to swelling or delamination of rubber) - Replace damaged tubes and hoses

Car pulls or skids when braking

Wheel cylinder piston jammed - Replace the cylinder, article - "Replacing the wheel cylinder"

Clogged brake lines: tubes (due to dents) or hoses (due to swelling or delamination of rubber) - Replace damaged tubes and hoses

Wheel jamming due to separation of the lining from the base of the brake pad - Replace the pad (preferably all on one axis at the same time)

Oiling of brake discs, drums, linings - Clean oily discs and drums, replace pads (as a last resort, sand them down).

It is strictly forbidden to clean the pads with solvents! Eliminate the cause of the oiling (replace the axle shaft seal)

An ice or salt crust has formed on the surface of the linings (in winter); the linings are wet - When starting to move, at low speed, check the brakes.

In the rain and after driving through deep puddles, dry the brakes by lightly pressing the brake pedal

Different pressure in the tires of the left and right wheels - Set the normal pressure

Significant difference in tire wear - Replace worn tire

Deformation of the brake disc - Replace the disc (preferably as a pair)

Ovality of brake drum - Grind or replace drum