The control device in the 21129 engine management system is the M86 engine management system controller (KSUD)

Based on the information received from the sensors, the controller calculates the fuel injection control parameters for high driving performance and low fuel consumption.

The controller is located in the engine compartment on the left strut of the front suspension.

The controller controls actuators such as fuel injectors, throttle an electric pipe, an ignition coil, an oxygen sensor heater, an adsorber purge valve and various relays.

The controller controls the switching on and off of the main relay (ignition relay), through which the supply voltage from the battery is supplied to the system elements.

The controller switches on the main relay when the ignition is switched on.

When the ignition is switched off, the controller delays the switching off of the main relay for the time required to prepare for the next switching on (completion of calculations, setting the throttle valve to the position preceding engine start).

The KSUD performs the immobilization function, exchanging codes with the CBKE (VSM controller).

If the exchange determines that the codes are incorrect, then the engine start blocking in the KSUD is not removed.

The controller also performs the system diagnostic function.

It determines the presence of malfunctions of the system elements, switches on the alarm and stores codes in its memory, indicating the nature of the malfunction and helping the mechanic to carry out repairs.

The LADA VESTA car has a data exchange interface between the ECM controller, the diagnostic socket and the controllers (control units) of other car systems via the CAN bus.

The CAN bus is used to exchange immobilizer codes between the ECM controller and the CBKE, exchange information about the operating parameters of the engine, transmission, ABS, sensor status, etc.

The CAN bus is a two-wire line:

- - low-level line CAN L (contacts "X1.1 / H5", "X1.2 / D5" of the ECM controller);

- - high-level line CAN H (contacts "X1.1 / H4", "X1.2 / D4" of the ECM controller).

The controller is a complex electronic device, the repair of which should be carried out only on manufacturer.

During operation and maintenance of the vehicle, disassembling the controller is prohibited.

Unauthorized modification of the controller software may lead to deterioration in engine performance and even to its failure.

In this case, the warranty obligations of the vehicle manufacturer for maintenance and repair of the engine and control system are lost.

The controller supplies various devices with a supply voltage of 5 V or 12 V.

In some cases, it is supplied through controller resistors with such a high nominal resistance that when the control lamp is connected to the circuit, it does not light.

In most cases, a conventional voltmeter with low internal resistance does not give accurate readings.

To monitor the voltage of the controller's output signals, a digital voltmeter with an internal resistance of at least 10 MOhm is required.

Memory controller

The controller has three types of memory: programmable read-only memory (ROM), random access memory (RAM), and electrically reprogrammable memory (ERPROM).

The controller's memory is non-volatile, i.e. its contents are retained when the power is turned off.

Read-only memory (ROM)

ROM stores the control program, which contains a sequence of operating commands and calibration information.

Calibration information is the control data for injection, ignition, idle speed, etc., which in turn depends on the weight of the vehicle, the type and power of the engine, the gear ratios of the transmission and other factors.

Random-access memory (RAM)

Random-access memory is used by the microprocessor for temporary storage of measured parameters, calculation results, and fault codes.

The microprocessor can enter data into RAM or read it as needed.

Electrically reprogrammable memory (EPROM)

EPROM is used to store controller, engine and vehicle identifiers, as well as immobilizer password codes.

The password codes received by the ECM controller from the CBKE are compared with those stored in the EPROM and are changed by the microprocessor according to a certain law.

To prevent damage to the controller when when connecting the wire from the negative terminal of the battery or the wiring harness from the controller, the ignition must be off.

If the controller is faulty, a "clean" (untaught) controller must be used for replacement.

Checking the controller's operability

1) After replacing the controller or resetting the controller using a diagnostic tool ("Function test; ECU reset with initialization" mode), it is necessary to perform the throttle valve zero adaptation procedure and the misfire diagnostic function adaptation procedure.

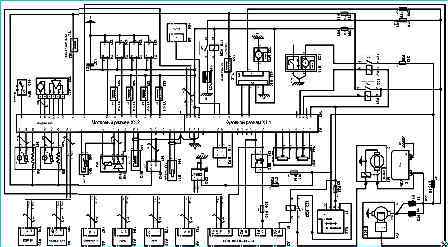

Wiring diagram of the M86 ECM of the LADA VESTA vehicle in the Comfort AT configuration with the M86 EURO-5 controller (21803-0000013-51):

Throttle valve zero adaptation procedure:

- with the vehicle stationary, turn on the ignition, wait 30 seconds, turn off the ignition, wait for the main relay to disconnect.

Adaptation will be interrupted if:

- - scrolls engine;

- - the vehicle is moving;

- - the accelerator pedal is pressed;

- - the engine temperature is below 5 °C or above 100 °C;

- - the ambient air temperature is below 5 °C.

The procedure for adapting the misfire diagnostics function:

- - warm up the engine to operating temperature (the value of the "Coolant Temperature" parameter = 60...90 °C);

- - accelerate the vehicle in 2nd gear until it reaches increased crankshaft speed (the value of the "Engine Crankshaft Speed" parameter = 4000 min-1) and perform engine braking ("Engine Crankshaft Speed" = 1000 min-1);

- - perform engine braking six times during one trip. 2) Perform diagnostics.

Assignment of contacts of the M86 controller

Contact - circuit

Connector X1.1

- A1, A2, A3, A4 - Not used

- A5 - Input. Terminal "15" of the ignition switch. The nominal voltage with the ignition on and the engine not running is 12 V. With the engine running - 13.5-15.2 V.

- B1, B2, B3 - Not used.

- B4, B5, C1 - Not used.

- C2 - Input. Discrete cruise control 1. Not used.

- C3 - Input. Discrete cruise control 2. Not used.

- C4 - Input. Brake pedal switch 1. When the brake pedal is released, the contact is supplied with voltage from the vehicle's electrical system from terminal "15" of the ignition switch.

- C5 - Input. Brake pedal switch 2. When the brake pedal is pressed, the contact is supplied with voltage from the vehicle's electrical system from terminal "30" of the ignition switch.

- D1 - Not used

- D2 - Output. 5 V supply for accelerator pedal position sensor 1. A 5 V reference voltage is supplied to the contact.

- D3 - Output. 5 V supply for refrigerant pressure sensor. A 5 V reference voltage is supplied to the contact.

- D4 - Input. Accelerator pedal sensor 1. When the accelerator pedal is released, the signal should be within 0.5…0.85 V. When the accelerator pedal is fully depressed, the signal should be within 4.19…4.59 V.

- D5 - Accelerator pedal sensor 1 ground. The voltage at the contact should be zero.

- E1 - Not used.

- E2 - Output. 5 V supply for accelerator pedal position sensor 2. A 5 V reference voltage is supplied to the contact.

- E3 - Input. Analog cruise control. Not used.

- E4 - Input. Accelerator pedal sensor 2. When the accelerator pedal is released, the signal should be within 0.25 ... 0.43 V. When the accelerator pedal is fully depressed, the signal should be within 2.095 ... 2.295 V.

- E5 - Accelerator pedal sensor 2 ground. The voltage at the contact should be zero.

- F1 - Not used.

- F2 - Output. Control of the air conditioning clutch relay (-). The control signal is discrete, the active level is low, no more than 1 V, issued when the air conditioner is allowed to turn on.

- F3 - Not used.

- F4 - Input. Refrigerant pressure sensor. The voltage at the contact depends on the refrigerant pressure in the air conditioning system.

- F5 - Refrigerant pressure sensor ground. The voltage on the contact should be zero.

- G1, G3 - Not used.

- G2 - Output. Control of starter relay 1 (-). Not used.

- G4, G5, H1 - Not used.

- H2 - Output. Control of engine cooling fan relay 1 (-). The supply voltage of the fan relay winding comes from the output (terminal "87") of the main relay.

The control signal is discrete, activeth level is low, no more than 1 V. The controller turns on the relay when the coolant temperature is above 102 °C, and also if there are coolant temperature sensor fault codes in the controller memory or when the air conditioner is running.

Н3 - Output. Control of relay 2 of the engine cooling system fan (-). The supply voltage of the fan relay winding comes from the output (terminal "87") of the main relay.

The control signal is discrete, the active level is low, no more than 1 V. The controller turns on the relay when the coolant temperature is above 103 °C, and also at high refrigerant pressure in the line both with the air conditioner running and without it.

- Н4 - Input/Output. CAN - H.

- Н5 - Input/Output. CAN - L.

- J1 - Not used.

- J2 - Output. Canister purge valve control (-). The supply voltage of the canister purge valve comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 1 V. The duty cycle changes depending on the engine operating mode in the range of 0 ... 100%.

J3 - Output. Main relay control (-). The supply voltage comes to the relay coil from the "plus" terminal of the battery. The control signal is discrete, the active level is low, no more than 1.5 V.

When the ignition switch is turned from the "off" position to the "on" position, the relay should turn on immediately. When the ignition switch is turned from the "on" position to the "off" position, the controller delays turning off the main relay for about 10 s.

- J4 - Output. Electric fuel pump relay control (-). The supply voltage of the electric fuel pump relay winding comes from terminal "15" of the ignition switch. The control signal is discrete, the active level is low, no more than 1 V, it is issued when fuel supply is enabled.

- J5 - Input. Request signal to turn on the air conditioner. In the absence of a request signal, this contact is connected to ground through the internal resistor of the controller.

When the air conditioner switch is turned on, voltage from the on-board network is supplied to the contact. On a car with a climate control system, this input is not used, the request signal to turn on the air conditioner comes to the ECM controller from the SAUCU controller via the CAN bus.

- K1, K2 - Not used.

- K3 - Input. On-board network voltage at the main relay output.

The voltage from the main relay output (terminal "87") when the engine is not running (for an unlimited time after turning on the ignition without starting the engine, as well as for 10 seconds after turning off the ignition) is 12 V. When the engine is running - 13.5-15.2 V.

- K4 - Ground of power stages. Used to connect the ground of the output keys for controlling actuators to the vehicle body.

- K5 - Ground of power stages. Used to connect the ground of the output keys for controlling actuators to the vehicle body.

- L1, L2 - Not used.

- L3 - Input. On-board network voltage at the main relay output. The voltage from the main relay output (terminal "87") when the engine is not running (for an unlimited time after turning on the ignition without starting the engine, as well as for 10 seconds after turning off the ignition) is 12 V. When the engine is running - 13.5-15.2 V.

- L4 - Ground of power stages. Used to connect the ground of the output keys for controlling actuators to the car body.

- L5 - Ground of the ignition power stages. Not used.

Connector X1.2

- A1 - Output. Throttle actuator - contact "1" (+).

- A2 - Output. Control of the oxygen sensor heater. The supply voltage of the oxygen sensor heater comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 2 V. The duty cycle varies in the range of 0...100% depending on the temperature and humidity in the sensor installation area.

A3 - Output. Control of the diagnostic oxygen sensor heater. The supply voltage of the oxygen sensor heater comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 2 V. The duty cycle varies in the range of 0...100% depending on the temperature and humidity in the sensor installation area.

- A4 - Output. Throttle actuator - contact "2" (-).

- A5, B1 - Not used.

- B2 - Output. Control of injector 1 cylinder (-). The supply voltage of the injector winding comes from the output (terminal "87") of the main relay. The control signal is pulsed, the active level is low, no more than 1.5 V. The duration depends on the engine operating mode and ranges from several to tens of milliseconds.

- B3 - Not used.

- B4 - Input. Crankshaft position sensor signal - contact "A". When the crankshaft rotates engine, there is an AC voltage signal on the contact, close in shape to a sine wave. The frequency and amplitude of the signal are proportional to the crankshaft speed.

- B5 - Input. Crankshaft position sensor signal - contact "B". When the engine crankshaft rotates, there is an AC voltage signal on the contact, close in shape to a sine wave. The frequency and amplitude of the signal are proportional to the crankshaft speed.

- C1 - Not used.

- C2 - Output. Control of the 2nd cylinder injector (-). The supply voltage of the injector winding comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 1.5 V. The duration depends on the engine operating mode and ranges from several to tens of milliseconds.

C3 - Output. Control of the 3rd cylinder injector (-). The supply voltage of the injector winding comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 1.5 V. The duration depends on the engine operating mode and ranges from several to tens of milliseconds.

- С4 - Input/Output LIN.

- С5 - Electronics ground. The voltage on the contact should be zero.

- D1 - Not used.

D2 - Output. Control of the 4th cylinder injector (-). The supply voltage of the injector winding comes from the output (terminal "87") of the main relay. The control signal is pulsed, the active level is low, no more than 1.5 V. The duration depends on the engine operating mode and ranges from several to tens of milliseconds.

- D3 - Not used.

- D4 - Input/Output. CAN - H.

- D5 - Input/Output. CAN - L.

- E1, E2 - Not used.

- E3 - Output. 5 V power supply for the throttle position sensors. A 5 V reference voltage is supplied to the contact.

- E4 - Input. Phase sensor signal. In the absence of a signal, the on-board voltage is supplied to this contact through the internal resistor of the controller. The sensor pulses the circuit to ground once per revolution of the camshaft, which allows for recognition of the firing order of the engine cylinders.

- E5, F1 - Not used.

- F2 - Output. Control of the intake manifold air damper valve. The supply voltage of the adsorber purge valve comes from the output (terminal "87") of the main relay.

- The control signal is pulsed, the active level is low, no more than 1 V.

- F3 - Output. 5 V supply of the absolute pressure sensor. A stabilized voltage of 5 V is supplied to the contact.

- F4 - Not used.

- F5 - Ground of the throttle position sensors. The voltage on the contact should be zero.

- G1 - Not used.

- G2 - Input. Throttle position sensor signal 1. When the ignition is on, there should be a DC voltage signal at the input, the value of which depends on the degree of opening of the throttle valve: with the valve fully closed 0.30 ... 0.58 V.

- G3 - Input. Throttle position sensor signal 2. When the ignition is on, there should be a DC voltage signal at the input, the value of which depends on the degree of opening of the throttle valve: with the valve fully closed 4.42 ... 4.70 V.

- G4 - Input. Signal of the control oxygen sensor. If the oxygen sensor temperature is below 150 °C (not warmed up), there is a voltage of 1.7 V at the contact.

When the oxygen sensor is warmed up, then with the engine running in closed loop mode, the voltage switches several times per second between a low value of 180 ... 250 mV and a high value of 850 ... 950 mV.

- G5 - Ground of the control oxygen sensor. The voltage at the contact should be zero.

- H1 - Not used.

- H2 - Input. Knock sensor signal - contact "1" (+). The signal is an alternating current voltage, the amplitude and frequency of which depend on the vibrations of the engine cylinder block.

- H3 - Input. Knock sensor signal - contact "2" (-). The signal is an alternating current voltage, the amplitude and frequency of which depend on the vibrations of the engine cylinder block.

- H4 - Input. Signal from the diagnostic oxygen sensor. If the oxygen sensor has a temperature below 150 °C (not warmed up), a voltage of 1.7 V is present at the contact.

- When the oxygen sensor is warmed up, then when operating in feedback mode and with a serviceable neutralizer in steady-state mode, the voltage should change in the range of 590 ... 750 mV.

- H5 - Ground of the diagnostic oxygen sensor. The voltage at the contact should be zero.

- J1 - Not used.

- J2 - Input. Signal from the intake air temperature sensor. The voltage on the contact depends on the temperature of the air entering the engine: at a temperature of 25 °C, the voltage is about 2.35 V. If the sensor circuit is open, the voltage on the contact is 5±0.1 V.

- J3 - Input. Coolant temperature sensor signal. The voltage on the contact depends on the temperature coolant: at a temperature of 20 °C, the voltage is about 3.0 V. If the sensor circuit is open, the voltage at the contact is 5 ± 0.1 V.

- J4 - Input. Signal from the absolute pressure sensor in the intake manifold. The voltage at the contact depends on the pressure in the intake manifold: with the ignition on and the engine not running, the voltage is about 4.07 V.

- J5 - Ground for absolute pressure, air temperature, and coolant temperature sensors. The voltage at the contact should be zero.

- K1, K2, K3, K5 - Not used.

- K4 - Input. The oil pressure sensor signal is discrete.

- L1, L2, L3, L4, L5, M1, M2, M3, M4, M5, N1 - Not used.

- N2 - Output. Control of the primary winding of the ignition coil of the 4th cylinder (-). The supply voltage of the primary winding of the ignition coil comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 2.5 V. The duration depends on the voltage of the on-board network - from several to tens of milliseconds.

N3 - Output. Control of the primary winding of the ignition coil of the 3rd cylinder (-). The supply voltage of the primary winding of the ignition coil comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 2.5 V. The duration depends on the voltage of the on-board network - from several to tens of milliseconds.

N4 - Output. Control of the primary winding of the ignition coil of the 2nd cylinder (-). The supply voltage of the primary winding of the ignition coil comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 2.5 V. The duration depends on the voltage of the on-board network - from several to tens of milliseconds.

N5 - Output. Control of the primary winding of the ignition coil of cylinder 1 (-). The supply voltage of the primary winding of the ignition coil comes from the output (terminal "87") of the main relay.

The control signal is pulsed, the active level is low, no more than 2.5 V. The duration depends on the voltage of the on-board network - from several to tens of milliseconds