To determine the destruction of the bearing, you need to jack up the car from the side being tested until the wheel lifts off the road

Place a strong stand (tripod) under the body sill and lower the car slightly to load the stand.

Roll the wheel in a vertical plane, holding the top with one hand and the bottom of the wheel with the other.

Increased knocking from the central part of the wheel indicates a large gap in the hub bearing.

Do not give in to the persuasion of “craftsmen” who recommend tightening the hub nut with a force higher than 225.0-250.0 Nm (22.5-25.0 kgf m) to eliminate gaps.

This may lead to bearing failure.

You can replace the bearing on a car without removing the steering knuckle or by first removing the steering knuckle

Use a slotted screwdriver to pry off the protective cap of the wheel hub

Remove the cap

The cap has a rubber sealing ring

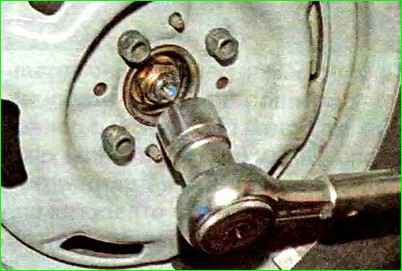

Use a beard to straighten the dented collar of the hub bearing nut in two places.

Tighten the parking brake, engage first gear and place shoes under the wheels.

Use a 30mm socket to loosen the hub bearing nut.

The nut is tightened with a large torque, so the head and knob must be strong enough to transmit the necessary force.

We hang up the front of the car (namely both front wheels, because otherwise the anti-roll bar interferes with dismantling, pressing the suspension elements upward).

Unscrew the hub bearing nut completely and remove the washer.

Remove the front wheel brake disc (see "Repair of the front wheel brake mechanism").

We remove the shank of the outer drive joint housing from the hub (see "Replacing parts of the front wheel drive of Lada Kalina").

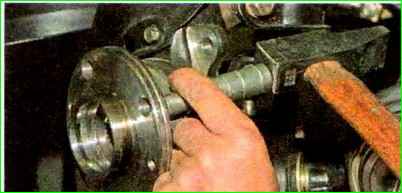

We connect the ball joint to the fist and compress the hub, striking it through a soft metal drift.

You can also compress the hub using the front wheel brake disc.

Pass M12x1.25 mm bolts about 130 mm long through two diametrically opposite holes in the disk (cylinder head mounting screws are suitable) and screw them into the holes of the hub to a depth equal to its thickness.

By sharply hitting the bolt heads with a disk, we compress the hub.

Then we use a cup puller to press the bearing out of the fist.

If it was not possible to remove the hub in this way, remove the steering knuckle.

To do this, unscrew the nuts of the bolts securing the shock absorber strut to the steering wheel varnish, remove the bolts (see "Replacing the front strut of a Lada Kalina car") and remove the steering knuckle.

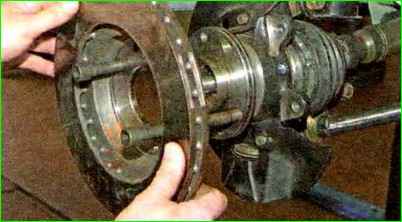

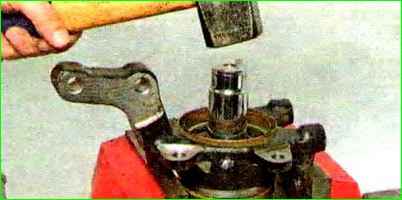

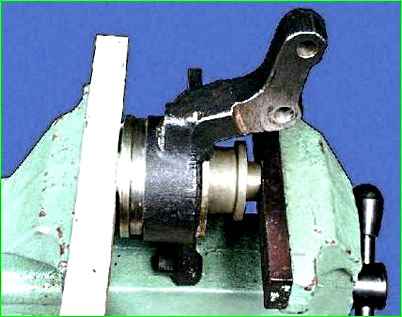

We install the steering knuckle on the jaws of the vice and press the hub out of the knuckle through a mandrel or head of a suitable diameter, applying force to the end of the hub.

Remove the hub from the fist.

In this case, the outer part of the inner ring of the bearing remains on the hub.

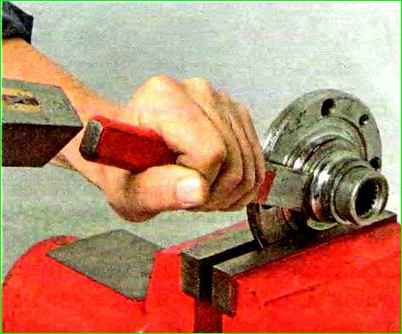

Remove the mud ring from the hub

Insert a blunt chisel between the ends of the inner ring of the bearing and the hub and, striking the chisel with a hammer, move the inner ring

Use a puller to compress the inner ring of the bearing

Use circlip pliers to remove the circlip.

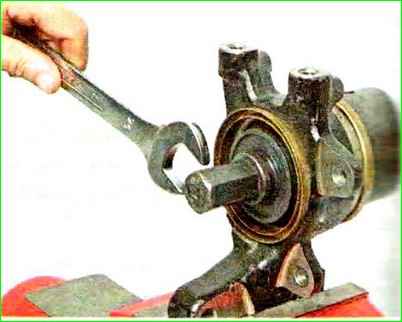

Use a cup puller to press the bearing out of the steering knuckle

Remove the bearing with a puller

Remove the bearing from the puller

If the hub bore diameter is damaged, replace it

The procedure for installing a new bearing is as follows:

Install the outer retaining ring after cleaning thoroughly.

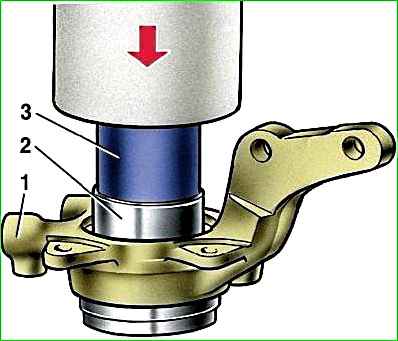

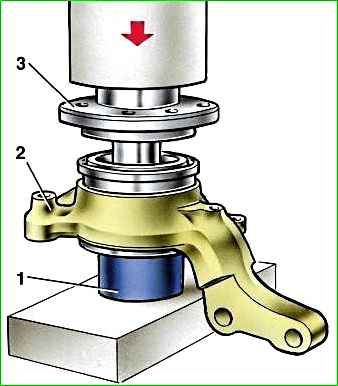

Using a mandrel, press the new bearing into the steering knuckle.

If there are no mandrels, you can use the rings of the old bearing

Press in the bearing and hub only using a press or in a vice.

Do not drive the bearing with a hammer - this will lead to its destruction.

When pressing a bearing, force must be applied only to its outer ring, otherwise the bearing may be damaged.

Install the inner retaining ring.

Using a mandrel, press the hub into the inner race of the bearing.

When pressing the hub, apply force only to the inner race of the bearing, otherwise the bearing may be damaged.

After replacing the bearing, reinstall the steering knuckle.