We bleed the hydraulic drive of the brake system after its repair, which resulted in a violation of the tightness of the system and if air is suspected of getting into the system

In the latter case, you must first determine and eliminate the cause of air getting into the hydraulic drive and only then begin bleeding it.

The presence of air in the hydraulic drive of the brake system is determined by the behavior of the brake pedal: it becomes soft (you can’t feel the stop at the end of the pedal stroke) and drops below its normal position.

To complete the work you will need an assistant, as well as:

- - a special wrench for the bleeder fitting or an 8 mm socket wrench;

- - transparent vinyl tube of suitable diameter;

- - container for draining brake fluid;

- - new brake fluid recommended by the manufacturer.

- - inspection ditch or overpass (preferably).

We prepare the car for work.

Disconnect the wiring harness block from the connector of the low brake fluid level sensor and remove the reservoir cap

To prevent air from entering the hydraulic drive of the brake system when bleeding the drive, make sure that the brake fluid level in the reservoir does not fall below the MIN mark.

If the rear axle of the car is suspended (the car is on a lift or placed on stands), the pressure regulator will block the path of brake fluid to the rear wheel cylinders

Therefore, to bleed the rear wheel cylinders, it is necessary to open the regulator valve.

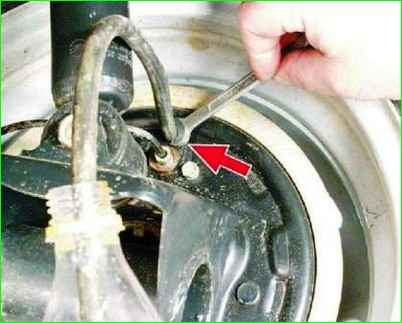

To open the pressure regulator valve, insert the blade of a slotted screwdriver between the lever and the plate, recessing the regulator rod.

Clean the air release valve on the brake mechanism from dirt and dust.

Check the level and, if necessary, add brake fluid to the reservoir to the “MAX” mark.

Remove the protective cap from the air release valve.

Place the rubber hose onto the valve head and immerse the end of the hose in a clean, transparent container partially filled with brake fluid.

The assistant must sharply press the brake pedal 4-5 times (with an interval between presses of 1-2 s).

After the last swing you need to keep the pedal pressed.

Unscrew the air release valve 1/2-3/4 turn.

Air bubbles will be visible in the liquid flowing from the hose.

When the fluid stops flowing from the hose, close the release valve completely, after which the assistant must release the brake pedal.

Repeat steps 5–6 until bubbles stop appearing in the flowing liquid.

When pumping, monitor the brake fluid level and, if necessary, add it to the reservoir, not allowing the level to drop below the “MIN” mark

Remove the hose, wipe the valve fitting dry and put the cap on it

Bleed the brakes of the remaining wheels, if necessary.

If there is no air in the system, the brake pedal should be “hard”, i.e. when pressing, go no more than half the distance to the floor.

Replacing brake fluid

To complete the work you will need an assistant, as well as a rubber bulb.

We prepare the vehicle and necessary equipment for the job.

Remove the tank cover

To prevent air from entering the hydraulic drive of the brake system, when replacing brake fluid, make sure that its level in the reservoir does not fall below the MIN mark.

Use a pear to remove the working fluid from the master brake cylinder reservoir.

Fill the tank with new fluid up to the top edge of the tank.

We pump the circuits of the hydraulic drive system, starting from the rear wheels of the car.

We bleed each wheel cylinder until new (lighter) brake fluid begins to emerge from the fitting.

After replacing the fluid in both circuits, we check the operation of the hydraulic drive and bring the fluid level in the master brake cylinder reservoir to normal.