Cylinder block, drive units and characteristics of engines KAMAZ 740.11-240, 740.13-260, 740.14-300, 740.11-3902007 RE

Technical characteristics of engines 740.11-240, 740.13-260, 740.14-300

- Engine type - compression ignition

- The number of bars is four

- Number of cylinders - eight

- V-arrangement of cylinders

- Camber angle - 90°

- Cylinder order 1-5-4-2-6-3-7-8

- Cylinder diameter and piston stroke, mm - 120x120

- Displacement, l - 10.85

Rated gross power, kW (hp) of the engine:

- 740.11-240: 176(240);

- 740.13-260: 191(260);

- 740.14-300: 220(300);

Maximum gross torque. Nm (kgf.m):

- 740.11-240: 833(85);

- 740.13-260:931(95);

- 740.14-300:951(97);

Crankshaft speed, min-1 nominal:

- 740.11-240: 2200;

- 740.13-260: 2200;

- 740.14-300: 2600;

Crankshaft speed, min-1 at maximum torque:

- 740.11-240: 1200-1600;

- 740.13-260: 1300-1500;

- 740.14-300: 1500-1800;

Crankshaft speed, min-1 at idle, no more: 600±50

Injection pump model:

- 740.11-240: 337-40;

- 740.13-260: 337-42;

- 740.14-300: 337-80.01;

Injector model:

- 740.11-240: 273-30;

- 740.13-260: 273-21 or 273-51;

- 740.14-300: 273-21 or 273-51;

Injector needle lift start pressure, MPa (kgf/cm2):

- - in operation, at least 19.61 (200)

- - new (factory adjustment) 21.37-22.36 (218-228)

Cylinder block of engines 740.11-240, 740.13-260, 740.14-300, 740.11-3902007 РЭ

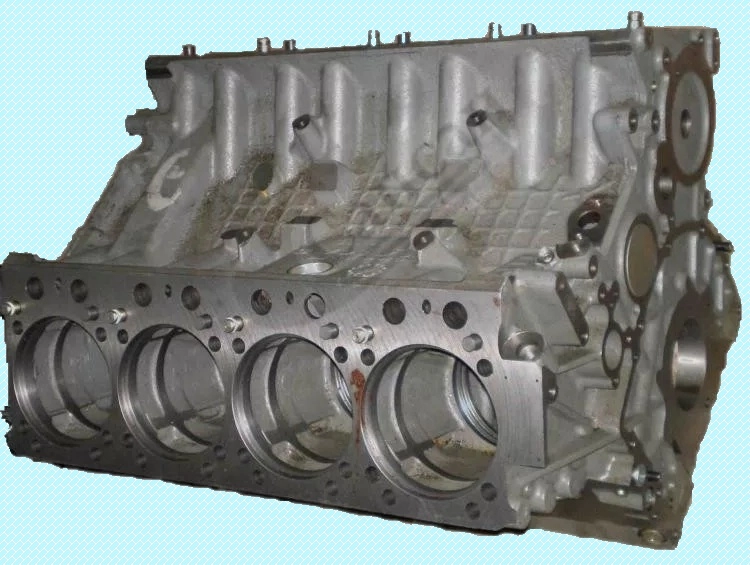

The cylinder block is the main body part of the engine and is a cast iron SCH25 GOST 1412-85.

The casting is subjected to artificial aging to relieve thermal stresses, which allows the block to maintain the correct geometric shapes and dimensions during operation.

Two rows of cylinder seats, molded in one piece with the upper part of the crankcase, are located at an angle of 90° to each other.

The left row of cylinders is shifted forward by 29.5 mm relative to the right row, which is due to the installation of two connecting rods side by side on each connecting rod journal of the crankshaft.

Each row has four cylinder sockets facing the upper machined planes, which serve as mating surfaces for cylinder heads.

The mating surfaces are highly flat and parallel to the axis of the bores for the crankshaft bearings.

Each cylinder seat has two coaxial cylindrical holes made in the upper and lower chords of the block, along which the cylinder liner is centered, and grooves in the upper chord, forming annular platforms for the sleeve collars.

In order to ensure the correct fit of the sleeve in the socket, the parameters of flatness and perpendicularity of the support platform under the shoulder of the sleeve to the common axis of the centering bores must be performed with high accuracy.

There are two grooves for O-rings on the lower belt, which prevent the coolant from getting from the cooling cavity of the block into the cavity of the engine oil crankcase.

Four bosses are evenly (around the cylinder) attached to the transverse walls of the block, which form a cooling jacket for each cylinder, for attaching the cylinder head with bolts.

The main bearing caps are connected to the crankcase by main and tie bolts.

The fifth main bearing cover is longitudinally centered on two vertical pins, ensuring that the bores match exactlye thrust half rings of the crankshaft on the block and on the covers.

The bore of the cylinder block for the main bearing shells is assembled with covers, so the main bearing caps are not interchangeable and are installed in a strictly defined position.

Each cover is marked with the serial number of the support, the numbering of the supports starts from the front end of the block

Parallel to the axis of the bores for the crankshaft bearings, bores are made into which the bushings of the camshaft of an increased dimension are pressed and bored compared to the bushings of the serial camshaft.

In the crankcase part of the collapse of the cylinder block, guides for the valve lifters are cast.

Note: During the transitional period of mastering the production, the engine can be used with a cylinder block with screwed pusher guides, with oversized camshaft bushings, without enlarged oil channels, with the tightening torques of the main bearing cap bolts:

- - pre-tightening - 95-120 Nm (9.6-12 kgf.m);

- - final tightening - 206-230 Nm (21-23.5 kgf.m);

- - tie bolts are tightened with a torque of 81-91 Nm (8.2-9.2 kgcm)

Closer to the rear end, between the fourth and eighth cylinders, a bypass pipe of the cooling cavity is made to improve the circulation of the coolant. At the same time, it also gives the block additional rigidity.

In order to increase the circulating oil supply, an oil pump with increased capacity is installed on the engine. Therefore, the diameters of the oil channels in the cylinder block are significantly increased.

In the lower part of the cylinders, together with the block, bosses are cast for the piston cooling nozzles.

In order to install on the filter unit with a heat exchanger on the right side, the platform has been enlarged and two additional mounting holes have been made, as well as a drain hole from the filter.

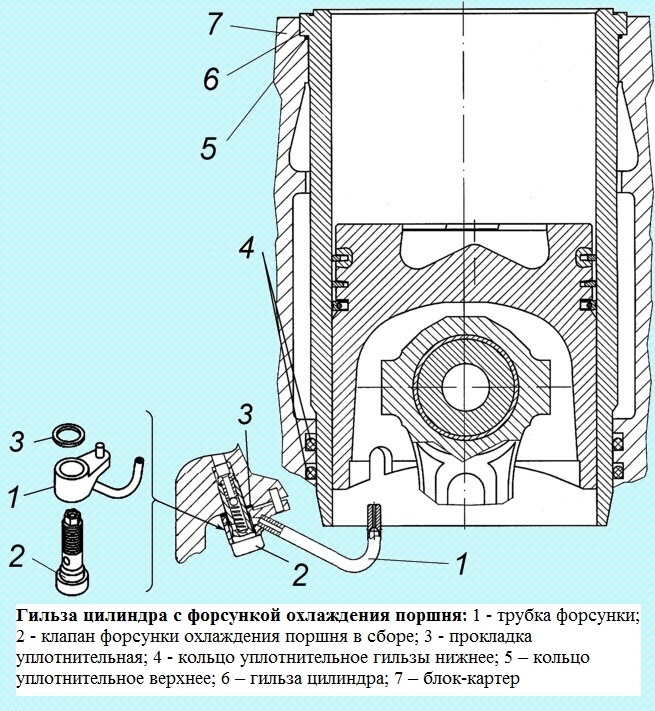

Cylinder liners (Fig. 3) "wet" type, easily removable. On the conical surface in the lower part, the cylinder liners have the following marking: installed on the engines 740.11-240 and 740.14-300 - 7406.1002021, on the engine 740.13-260 - 740.13-1002021.

Cylinder liner 7406.1002021 is made of gray special cast iron, hardened by bulk hardening, it differs by a reduced (in height) collar tempering zone from heat treatment of liners marked 740.1002021-20.

Sleeve 740.13-1002021 is made of special, alloyed gray cast iron and is not heat treated

Installing liners with inappropriate markings on engines leads to accelerated wear of liners and piston rings.

The mirror of the case is a rare grid of depressions and platforms at an angle to the axis of the case.

When the engine is running, the oil is retained in the depressions, which improves the running-in of parts of the cylinder-piston group

In the liner - cylinder block connection, the cooling cavity is sealed with rubber O-rings.

In the upper part there is a ring in the groove of the liner, in the lower part there are two rings in the bores of the cylinder block.

Aggregate drive

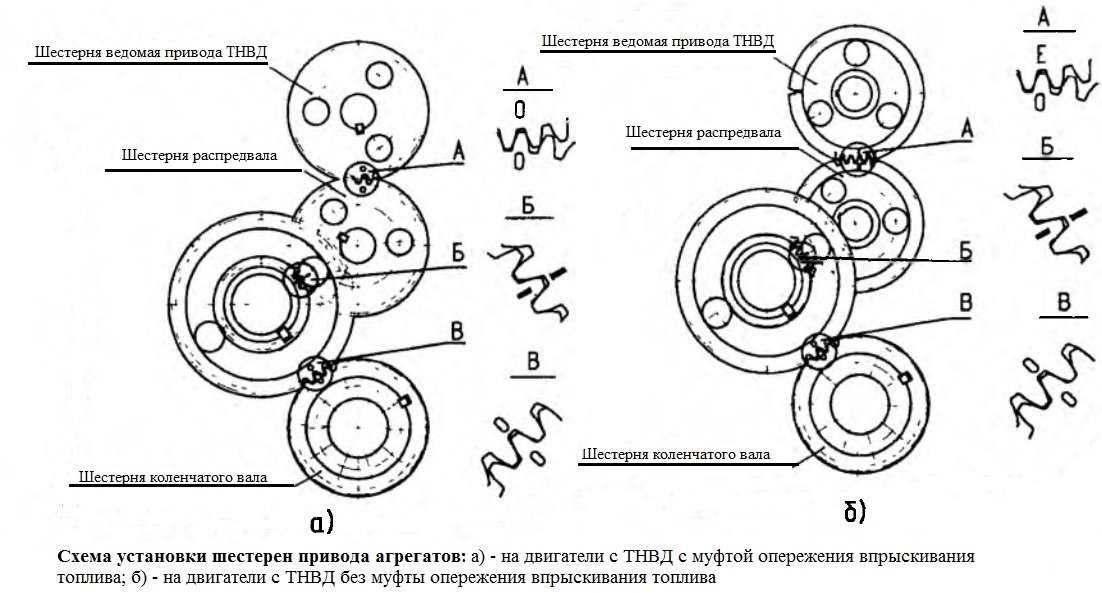

The drive of the units (Fig. 4) is carried out by gears with straight teeth, it serves to transmit torque to the shafts of the gas distribution mechanism, the high-pressure fuel pump, the compressor and the power steering pump of the car.

The timing mechanism is driven by a drive gear mounted on the crankshaft through a block of intermediate gears that rotate on a double tapered roller bearing located on an axle mounted on the rear end of the cylinder block.

The gear is pressed onto the end of the camshaft, and the angular position relative to the cams of the shaft is determined by the key.

The injection pump drive gear is mounted on the oversized injection pump drive shaft.

Therefore, the injection pump drive shaft for engines of models 740.10 and 7403.10 is not interchangeable with the drive shaft for engines of models 740.11; 740.13 and 740.14.

The gears are mounted on the engine in a strictly defined position according to the marks "E", "0" and the risks knocked out on the gears, as shown in fig. 4.

The injection pump is driven by a gear meshed with the camshaft gear.

The rotation from the shaft to the injection pump is transmitted through the driving and driven coupling halves with elastic plates, which compensate for the misalignment of the installation of the injection pump shafts and gears.

The gears of the pneumatic compressor drive and the power steering pump are engaged with the injection pump drive gear.

The drive of the units is closed by the flywheel housing, mounted on the rear end of the cylinder block.

On the right side of the crankcase there is a flywheel lock used to set the fuel injection advance angle and regulate thermal gaps in the gas distribution mechanism.

The latch handle is set in the upper position during operation.

It is transferred to the lower position during adjustment work, in this case the latch is engaged with the flywheel.

In the upper part of the flywheel housing there are bores into which the pneumatic compressor and power steering pump are installed.

The design of the flywheel housing is made for the installation of a single-cylinder pneumatic compressor.

In the flywheel housing, unlike the flywheel housing operated with a two-cylinder air compressor, there is no flywheel housing insert and a side oil supply channel to the air compressor.

Therefore, the installation of a two-cylinder pneumatic compressor on the engine is possible only with the obligatory replacement of the flywheel housing.

On the sides of the flywheel housing in the middle part there are two bosses with holes with a diameter of 21.3 mm for draining oil from the turbocharger.

In the lower left part of the crankcase there is a bore into which the starter is installed. In the middle of the crankcase, a bore is made for the crankshaft collar.

From the side of the rear end there is a bore for the clutch housing.

In the left part of the flywheel housing there is a lug with a flange and a hatch for installing a power take-off from the engine. In the absence of a power take-off, the hatch is closed with a plug installed on a liquid gasket.