Checking and replacing ball joints of the GAZ-3110 steering linkage

Check the lateral play in the hinge. To do this, set the wheels to the position where the car is moving in a straight line and rock the steering wheel in both directions

In this case, an assistant should put his hand on the ball joint, and if play is felt, it is necessary to check the condition of the joint parts.

If there is no wear on the conical seat of the rod and the ball pin, it is enough to tighten the fastening nut with a torque of 40–50 Nm (4.0–5.0 kgf m).

If there is wear, replace the defective parts.

Check the axial play in the hinge. To do this, vigorously shake the steering rod along the hinge axis.

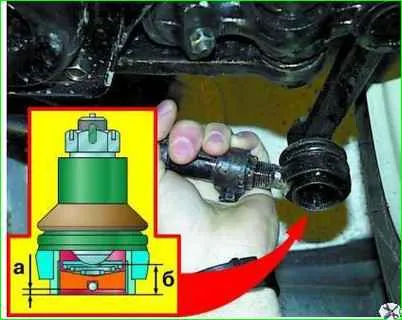

If play is detected, remove the cotter pin, screw in the plug until it stops and measure the distance “a” from the plug to the end of the hinge body.

If the value “a” of the plug’s recess is less than 5.5 mm, then the hinge can be adjusted; if it is more, unscrew the plug, remove the spring with the support heel and measure the distance “b” from the pin to the end of the hinge body.

If dimension “b” is no more than 16 mm, it is necessary to wash all the parts of the hinge, assemble the hinge, put fresh lubricant in it and adjust it.

If dimension “b” exceeds the specified value, replace the hinge.

Replacing the ball joint

Press the ball joint pin out of the mating rod or lever boss.

Remove the rubber joint seal.

Screw the fastening nut onto the pin flush with the end of the pin so as not to damage the thread of the pin when pressing it out.

Press the hinge out of the rod or lever boss.

Remove the rubber seal from the new ball joint. The hinge and seal contain the required amount of lubricant.

When installing the hinge, make sure that no dirt gets into it or into the seal.

Press the hinge into the rod or lever boss until it stops.

Install the seal, and place the outer edges of the tie rod ball joint seal onto the collar of the tie rod boss.

Adjusting the hinge

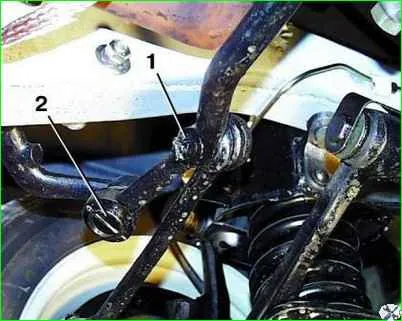

Remove cotter pin 1 and screw in plug 2 until it stops.

Unscrew the plug one turn for the outer tie rod joints or half a turn for the inner tie rod joints, bipod link joints and swing arm.

Then unscrew the plug until the slot of the plug first aligns with the hole in the housing for the cotter pin.

Install the cotter pin.

Filling the steering joint with grease

Clean the ball joint from dirt.

Remove cotter pin 1, unscrew plug 2, remove spring and heel.

Insert Litol-24 grease into the hinge and screw in the plug until it stops, while pressing on the end of the rod so that the grease penetrates into the rubber seal into the gap formed between the pin and the bearing housing.

After this, unscrew the plug, assemble the hinge and adjust it