The head is cast from aluminum alloy AK6M2.

There are additional racks for fastening the rocker arm axle

The bushings of all valves are equipped with sealing caps made of rubber based on fluorine rubber.

Removing and installing the cylinder head

Drain the coolant

Removing the carburetor

Remove the intermediate lever with the carburetor control rods, disconnect the hose of the vacuum brake booster

Disconnect the exhaust pipe from the exhaust manifold

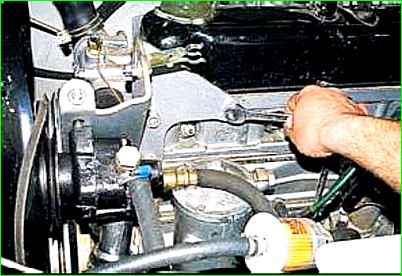

Disconnect the hose from the heater tap (Fig. 1).

Remove the tips of the high-voltage wires from the spark plugs.

Remove the drive belt from the power steering pump pulley

Use a 13mm wrench to unscrew the rear fastening nut of the power steering pump bracket and a 17mm wrench to unscrew the two front fastening nuts.

Remove the bracket together with the pump.

Disconnect the wire tip from the temperature indicator sensor

Remove the upper radiator hose (Fig. 4)

Disconnect the hoses from the thermostat housing.

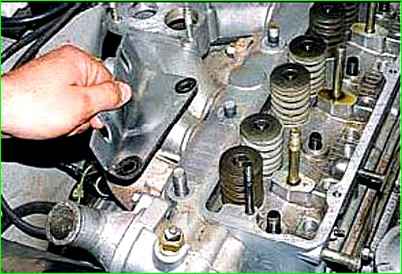

Remove the rocker arm axle and take out the push rods.

Using the “17” socket, evenly, in the reverse tightening sequence (see below), unscrew the nuts securing the block head (Fig. 5).

Remove the air filter housing mounting bracket and the mounting eye from the studs.

Remove the cylinder head.

Remove the head gasket.

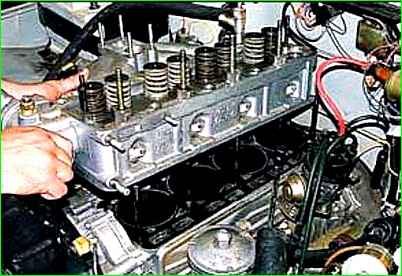

To check the flatness of the block head, apply a bench ruler to the thoroughly cleaned plane of the head in two diagonal directions.

The gap when measured with a feeler gauge should be no more than 0.1 mm.

Otherwise, the head must be ground or replaced.

When installing the head, be sure to install a new gasket, rubbing it on both sides with graphite powder (soft pencil).

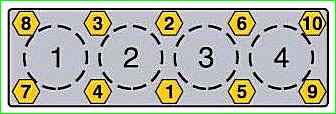

Lubricate the threads of the studs with graphite grease or CV joint-4, after which we evenly tighten the ten nuts securing the block head with a “17” head in the order according to the figure.

To ensure a uniform and tight fit of the cylinder head to the block, tightening the fastening nuts should be done on a cold engine in a certain sequence in two stages:

- - first - preliminary, with less effort;

- - second - finally, tightening the nuts evenly with a torque of 88.3-93.2 Nm (9-9.4 kg/cm.

After tightening the fastening nuts, be sure to check the thermal clearances between the valves and rocker arms.

Tightening must be done with a torque wrench