Pistons - nominal diameter 100 mm, with a conical recess on the bottom, with a thermostatic insert, cast from an aluminum alloy and coated with tin

There are three grooves in the upper part for piston rings.

Piston pins are floating type with a diameter of 25 mm, hollow. To increase fatigue strength, the inner surface of the pins has improved surface finish.

Connecting rods are steel, I-section. the length of the connecting rod is increased by 7 mm compared to the connecting rods of the ZMZ-4025, ZMZ-4026 engines.

The diameters of the upper and lower connecting rod heads coincide in size with the connecting rods of the ZMZ-4025, ZMZ-4026 engines.

The crankshaft is five-bearing, cast from special high-strength cast iron and has all journals hardened with high-frequency currents.

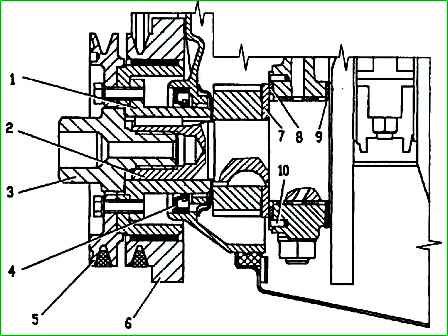

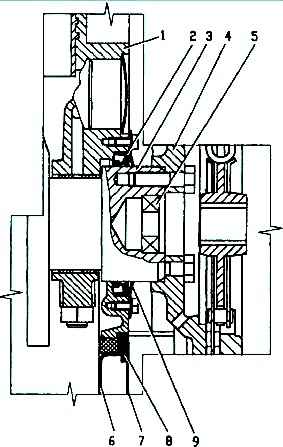

The front end of the crankshaft is sealed with oil seal 4, which runs along the outer surface of the pulley hub.

The rear end is sealed with oil seal 2, running along a special neck with a diameter of 80 mm.

The neck is hardened by high frequency currents.

The axial force is perceived by the front crankshaft support through two thrust washers.

The main and connecting rod bearings of the crankshaft are made of steel strip filled with an antifriction alloy.

Flywheel - cast iron with a steel toothed rim for starting with a starter; balanced as an assembly with the crankshaft and clutch.

The flywheel is attached to the crankshaft (to the end of the journal with a diameter of 80 mm) by seven self-locking bolts M 10×1.25 mm.