Clutch - single-plate, dry, with a diaphragm-type central spring

Located in an aluminum crankcase, structurally integrated with the gearbox and attached to the engine cylinder block

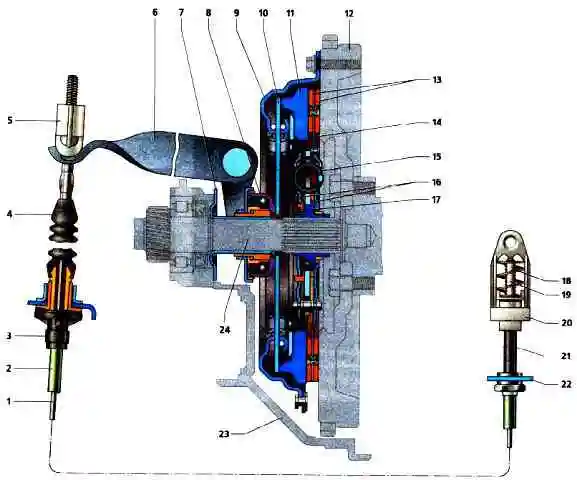

Clutch and its drive: 1 - clutch drive cable; 2 - cable sheath; 3 - lower tip of the cable sheath; 4 - protective cover; 5 - leash; 6 - fork lever; 7 - bearing guide sleeve; 8 - clutch release bearing; 9 - clutch casing; 10 - pressure spring; 11 - pressure (drive) clutch disc; 12 - flywheel; 13 - friction linings of the driven disk; 14 - driven disk; 15 - damper spring; 16 - torsional vibration damper; 17 - driven disk hub; 18 - spring; 19 - toothed cable tip; 20 - housing of the automatic cable length adjustment mechanism; 21 - spacer sleeve; 22 - cable sheath bracket; 23 - clutch housing; 24 - gearbox input shaft

The clutch housing is connected by six bolts to the engine flywheel.

The flywheel has three pins, which, when installing the clutch, fit into the corresponding holes in the casing, centering it.

Three pairs of elastic steel plates connect the casing to the pressure (drive) disk.

The complete basket is balanced on a stand, so it is replaced entirely.

Replacement of the basket is necessary when there is ring wear on the pressure spring petals to a depth of more than 0.8 mm, as well as when there is significant wear on the surface of the pressure disk or “settlement” of the spring.

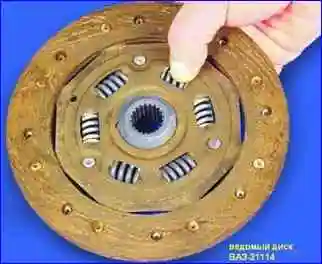

The driven disk with a spring torsional vibration damper is located on the splines of the gearbox input shaft between the flywheel and the pressure plate.

The driven disk is replaced if there is axial runout in the area of the friction linings, weakening of the rivet joints, and also if the rivet heads are recessed from the surface of the linings by less than 0.2 mm.

Clutch drive - cable, backlash-free with automatic adjustment of cable length.

A plastic leash is screwed onto the threaded end of the cable, which is inserted into the clutch release fork lever.

During the operation of the vehicle, the linings of the driven disk wear out, as a result of which the clutch release fork lever moves forward (along the vehicle).

Since the cable is connected to the fork lever, the length of the cable must be increased when the linings wear out to maintain normal travel of the clutch pedal.

The cable length is changed automatically using a regulator located in the upper end of the cable and connected to the clutch pedal.

Therefore, during operation, adjustment of the clutch cable is not provided.

The mechanism for automatically adjusting the length of the cable consists of a plastic housing into which a toothed cable tip is inserted, held in the housing by two spring-loaded clamps.

The mechanism also includes a spacer sleeve placed on a cable, one end of which fits into the mechanism body.

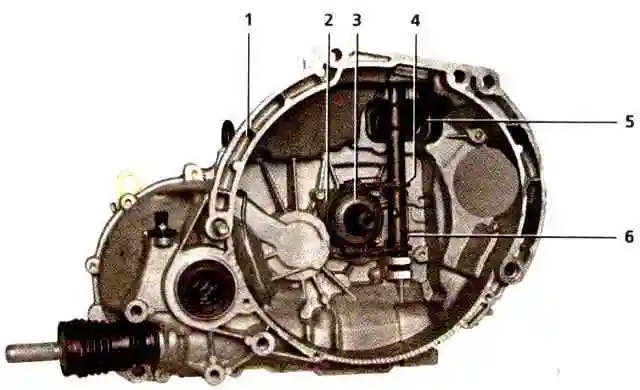

Elements of the clutch drive mechanism: 1 - clutch housing; 2 - clutch release bearing guide sleeve; 3 - clutch release bearing with casing assembly; 4 - clutch release fork; 5 - dirt-proof cover; 6 - bearing spring bracket

When the pedal is pressed, the spacer moves away from the cable sheath bracket and does not press on the mechanism clamps.

In this case, the mechanism body is rigidly connected to the cable.

If the driven disk linings are not worn, then when the pedal is released, the bushing only touches the bracket and does not release the clamps - the toothed tip of the cable does not move relative to the body.

As the linings wear, the clutch release fork lever with the threaded end of the cable moves forward (in the direction of the vehicle), tensioning the cable.

In this case, the spacer sleeve, resting against the bracket, releases the spring-loaded clamps, and the toothed tip of the cable moves out of the housing by the amount necessary to compensate for the wear of the linings.

The clutch pedal is mounted on an axle in the pedal assembly bracket.

A clutch release bearing with housing assembly is installed between the clutch release fork and the pressure spring petals.

The bearing housing is pressed against the fork legs by a spring clip.

The bearing moves freely along a guide sleeve mounted on the clutch housing.

When the clutch pedal is pressed, the cable acts on the clutch release fork lever, which moves the bearing.

The bearing presses on the petals of the clutch pressure spring, while the pressure plate moves away from the flywheel, as a result of which the engine crankshaft and the transmission input shaft can rotate independently of each other.

Possible clutch malfunctions and methods of elimination

Possible clutch malfunctions and methods of elimination

- Cause of malfunction

Elimination methods

Clutch slips

(when the accelerator pedal is sharply pressed, the engine gains speed, but the car hardly accelerates):

- Oiling of the flywheel, pressure plate, friction linings of the driven disk

Rinse oily surfaces thoroughly with white spirit or gasoline and wipe them dry. Replace the heavily oiled driven disk. Eliminate the cause of oiling (oil leakage through the engine or gearbox seals)

- Reducing the force of the diaphragm spring

Replace the pressure plate assembly (“basket”)

- Severe wear or burning of the friction linings of the driven disk

Replace the driven disk

- Damage or jamming of the clutch drive

Remove jam. If necessary, replace drive parts

The clutch drives (it is difficult to change forward gears, the reverse gear engages with noise, the gearbox is working):

- Incorrect adjustment of the clutch drive (full pedal travel is insufficient)

Adjust the drive. Replace the deformed clutch fork

- Clutch cable jamming

Lubricate the cable with engine oil. If this does not help (the cable wires are frayed, the sheath is damaged), replace the cable

- Loosening of rivets or breakage of friction linings, warping of the driven disk (end runout more than 0.5 mm)

Replace the drive

- Severe and uneven wear, scuffing on the working surfaces of the flywheel or pressure plate

Replace the flywheel. If the surface of the pressure plate is damaged, replace the housing with the pressure plate assembly (“clutch basket”)

- Jamming of the driven disk hub on the splines of the input shaft of the gearbox

Clean the splines from dirt, remove minor damage with a file.

If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft.

Before assembly, apply fresh CV joint-4 grease to the splines

- Skewed or warped disc

Replace the housing with the pressure plate assembly (“clutch basket”)

Jerking when starting off:

- Clutch cable jamming

Lubricate the cable with engine oil. If this does not help, replace the cable

- Jamming of the driven disk hub on the splines of the input shaft of the gearbox

Clean the splines from dirt, remove minor damage with a file.

If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply fresh CV joint-4 lubricant to the splines

- deformation of the driven disk

Replace the driven disk

- Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings

Replace the driven disk

- Loss of elasticity of the spring plates of the driven disk

Replace the driven disk

- Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs

Replace the driven disk

- Seizures on the working surfaces of the flywheel or pressure plate

Replace the flywheel or clutch housing with pressure plate assembly (clutch basket)

- Oiling of the working surfaces of the friction linings of the driven disk

Rinse oily surfaces thoroughly with white spirit or gasoline and wipe them dry. Replace the heavily oiled driven disk. Eliminate the causes of oiling

Rattling, knocking or noise when engaging the clutch:

- Significant settlement or breakage of torsional vibration damper springs, wear of windows for springs

Replace the driven disk

- deformation of the driven disk

Replace the driven disk

- Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings

Replace the driven disk

Increased noise when disengaging the clutch:

- Wear, damage or leakage of grease from the clutch release bearing

Replace the bearing