To compensate for the thermal expansion of the valve stem, a gap is required between the camshaft cam and the valve lifter

For inlet valves, the gap should be 0.15-0.25 mm, and for exhaust valves - 0.30-0.40 mm.

The gap is set by selecting the thickness of the shims.

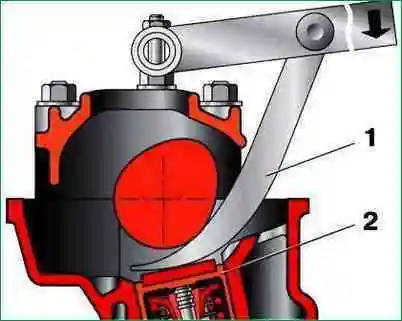

The washers are installed in a niche located on the pushers from above.

To make it easier to remove the washers, grooves are made on the upper edges of the pushers.

Checking and adjusting the gaps is performed on a cold engine (at a temperature of +20 °)

The size of the washer is marked on its non-working surface.

Preparing the car for work.

Remove the cylinder head cover.

Remove the front timing belt cover4.

Use a medical syringe or a rubber bulb to remove the remaining oil around the valve lifters.

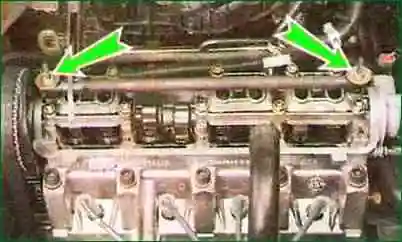

We install the valve adjuster on the cylinder head studs and fix it with the nuts that fastened the cylinder head cover.

There are several ways to adjust gaps. They differ in the order in which valve clearances are measured.

In any case, the gaps are checked only when the valves are closed (their pushers are not pressed by the camshaft cams).

If it is difficult to determine the position of the valves, the method below should be followed.

By turning the crankshaft clockwise, we set the piston of the first cylinder to the TDC position of the compression stroke.

The crankshaft can be rotated with a 17 mm spanner for its pulley bolt or with a large slotted screwdriver for the flywheel teeth.

To do this, remove the bottom cover of the clutch housing

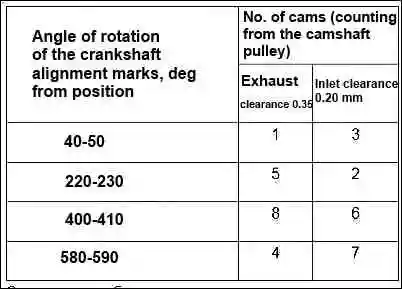

By turning the shaft from the TDC position at an angle of 40-50 (by 3 teeth of the camshaft pulley), we determine the gaps in the drive of 1 and 3 valves (when counting in order from the camshaft pulley).

The nominal thickness gauge should be slightly pinched in the gap between the camshaft cam and the tappet shim.

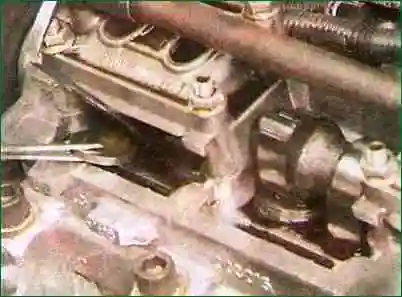

If the gap does not correspond to the norm, turn the pusher with the groove towards you.

Using the device, we sink the valve, keeping the pusher from rotating with a screwdriver inserted into the groove.

We lock the pusher in the lower position with the fixture lock.

Remove the adjusting washer with tweezers

By marking on the washer we determine its thickness. If the inscription is erased, measure the thickness of the washer with a micrometer

We calculate the gap of the new shim using the formula:

a) for inlet valves

Z = Y + X - 0.2 mm;

b) for exhaust valves

Z = Y + X - 0.3 mm;

- where Z is the calculated thickness of the new shim, Y is the thickness of the removed shim; X - gap determined by the probe

We select a new washer whose thickness is close to the calculated one (± 0.05 mm).

We install a new washer in the pusher (marked down).

We press the pusher with the fixture and remove the latch.

Following the sequence indicated in the table, we check and adjust the clearances in the drive of other valves.

Having removed the valve adjuster, install the removed parts in the reverse order of disassembly.