Adjusting the content of carbon monoxide (CO) in exhaust gases ZMZ-406

The adjustment is made on a warm engine (coolant temperature 80-90 ° C) with a working ignition system and nominal gaps between the spark plug electrodes

The content of CO and CH in the exhaust gases should be within:

- 0.7-0.9% CO and 1200 ppm -1 CH at crankshaft speed (800+50) min -1

- no more than 0.5% CO and 600 ppm -1 CH at crankshaft speed (3150+50) m -1.

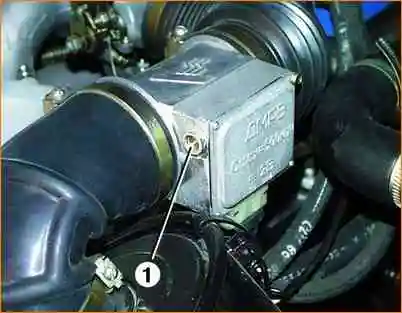

If the CO content is above the specified limits, adjust the CO content with screw 1 on the mass air flow sensor.

Turning the screw clockwise increases the CO content and decreases it counterclockwise. In this case, the content of CH will also be adjusted.

If it is not possible to adjust the content of CO and CH within the specified limits, it is necessary to check the serviceability of the elements of the integrated microprocessor engine control system.

Before adjusting, check the serviceability of the KMSUD, the ignition system, the condition of the candles, etc. (see the relevant sections).

To carry out the adjustment, we warm up the engine to the operating temperature of the coolant (80–90 ° C).

Insert the gas analyzer tube into the muffler pipe and wait for the gas analyzer readings to settle (become stable).

At a frequency of 800 ± 50 min -1, turn the adjusting screw located in the mass air flow sensor housing with a screwdriver.

Turn clockwise to increase the CO content, counterclockwise to decrease it. Thus, we set the CO content within 0.7–0.9%.