Rear wheel brake mechanisms ZIL-5301

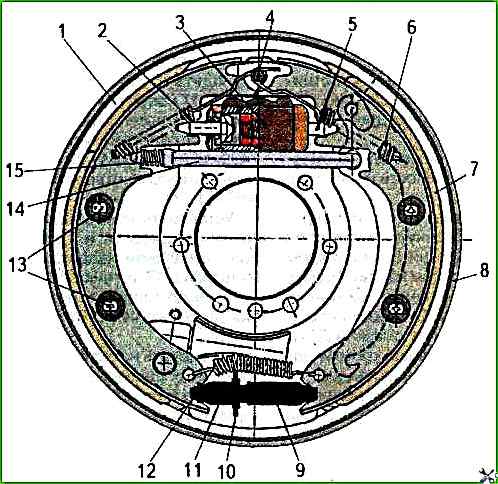

Rear wheel brake mechanisms are shoe-type, drum-type. The brake mechanism design is shown in Fig. 1

To disassemble the rear wheel brake mechanism, clean the brake drum from dirt and make sure it rotates freely.

The parking brake system must be in the released state.

Unscrew the six bolts securing the brake drum to the rear wheel hub and remove it, turning it so that the protrusions on the drum coincide with the grooves on the hub.

To remove the shoes, use a wire loop or hook to remove springs 2 and 6 from support pin 4; disassemble the rods 13 that secure the shoes to the brake shield 8, sinking the upper cup and turning it until the groove in the cup matches the position of the rod, remove the tension spring 12.

Disconnect the release lever 14 of the parking brake and the spring 15 from the shoes.

After disassembling the brake mechanism, all parts must be washed with a cleaning solution MS-6 or MS-8 TU 6-12-978-76, blown with compressed air and carry out a defect inspection

Inspect the inner working surface of the drum and check the thickness of the linings on the primary 1 and secondary 7 shoes.

Cracks and chips on brake parts are not allowed.

Damage to the thread is allowed no more than two threads.

Wear of the brake linings are allowed up to a level of 1.5 mm to the rivet heads.

If the brake parts wear out beyond the permissible dimensions, the worn parts must be replaced.

It is recommended to correct the bending of the brake shield by straightening.

If the bending is greater, the shields must be replaced.

When assembling the rear wheel brake mechanism, all operations must be performed in the reverse order of disassembly.

In this case, keep in mind the following.

The positions of the secondary and primary shoes and shoe springs must not be interchanged.

The primary brake shoe differs from the secondary one in that it has a larger number of turns and a smaller wire diameter.

When installing the tension spring 12 (see Fig. 1) and adjusting screw 10, nut 9 should be tightened to compensate for the thickness of the new linings.

If only one brake pad on the rear wheels of the car is worn out, all four rear brake pads should be replaced.

During assembly, the bearing surfaces of the bushings and axles should be lubricated with a thin layer of grease.

Gluing new linings to the brake pads.

If necessary, you can replace the brake linings on the pads by gluing new ones.

To ensure reliable gluing of the friction linings to the brake pads, the following conditions must be met.

Glue with glue grade VS-10T GOST 22345-77 or TIIR-4 TU 38.114513-96 from the company JSC SNIIATI (city of Yaroslavl).

Before gluing the linings, the brake pads must be cleaned by mechanical processing from traces of the old ones, provided that the geometric shape is preserved according to the drawing.

After mechanical processing of the pads, contamination of the prepared surface with dust, oil and other substances that weaken the adhesive bond is not allowed.

On the inner surface of the linings, the glossy layer must be removed, while maintaining the geometric dimensions of the product. Unevenness, cracks, traces of oil and contamination of the surface are not allowed.

A uniform layer of glue is applied with a brush to the clean, degreased surfaces of the pads and linings at a rate of 1.5-2 g per 100 cm 2 of area.

After applying the glue, the parts must be dried in the air for at least 15 minutes and no more than 90 minutes at a temperature of at least 15 ° C.

Touching the surface coated with glue with your hands is not allowed.

The parts must be glued in a special device that ensures the correct relative position of the lining and the pad and with the lining pressed against the pad with a force of 49-78 N / cm 2.

The parts must be glued in a drying oven at a temperature of 180 ° C, for 120 min, excluding the time it takes to heat the oven to the specified temperature.

After gluing the pads, the product must be checked for cracks, chips, distortion, absence of a gap between the pad and the block, and compliance with the drawing.

The strength of the adhesive joint must correspond to GOST R ISO 6312-93. The breaking force must be at least 100 N/cm 2.

Adjusting the rear wheel brakes

As the friction linings wear out, it is necessary to adjust the gap between the shoe lining and the drum every 4000 km.

To adjust, do the following:

- 1. turn off the parking brake;

- 2. lift the rear wheels;

- 3. remove the spring plugs from the rear brake shields;

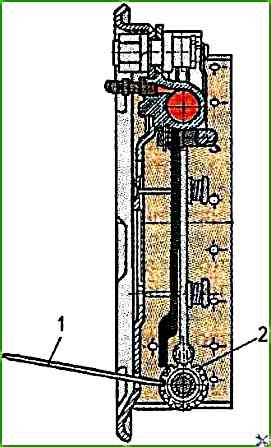

- 4. through the hole in the brake shield, use a special blade 1 (or a wide screwdriver) to rotate the sprocket of the adjusting screw 2 (on the left brake from the bottom up; on the right - in the opposite direction), spreading the pads until the wheel is braked (it does not turn by hand).

By rotating the sprocket in the opposite direction, ensure free rotation of the wheel;

- 5. insert the spring plugs.