ZIL-5301 Clutch Release Drive

ZIL vehicles and buses use a hydraulic clutch drive with a pneumatic booster.

As a rule, the pneumatic-hydraulic booster (PGU) is disassembled for repair in the following cases:

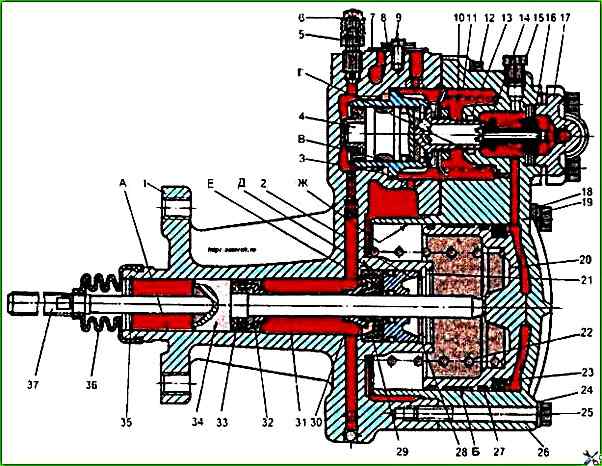

- fluid leakage through cuffs 29, 33 (Fig. 1), due to their swelling when using low-quality fluids; when the cuff of the pneumatic piston 23 is worn out.

The probability of failure of other parts is small.

The disassembly procedure is given below. Remove cover 36 with pusher 37 from the PGU.

Secure the PGU in a vice, pointing the front housing 26 upwards.

Unscrew connecting bolts 12 (2 pcs.), 19 and 25 (5 pcs.). The last thing to unscrew is bolt 19, located in the area of the gearbox

In this case, you should hold the housing 26, since springs 11 and 22 act on it.

Remove the housing 26, springs 11 and 22, diaphragm 10 assembled with the seat.

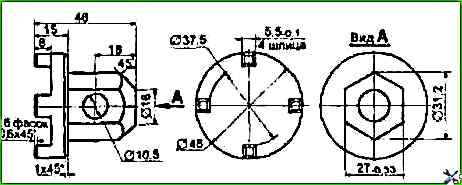

Using a special key (Fig. 4-13), unscrew the housing of the follower piston of the gearbox 4 from the rear housing 1 (see Fig. 1).

Remove the rear housing 1 of the amplifier from the vice.

Remove the retaining ring 35 and remove the clutch release piston 34 from the rear housing as an assembly, pushing it out by the protruding rod on the side of the seal 2.

Remove the spacer sleeve from the piston rod 34 30, spring 31, bushing 32 and cuff 33.

Remove retaining ring 21 of clutch release piston rod seal and washer 28.

Press cuff 29 and seal 2 of clutch release piston rod out of rear housing.

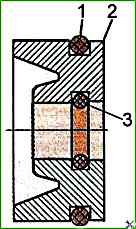

Remove piston seals, rubber rings 1 and 3 from housing 2 (Fig. 4-14). On housing 1 (see Fig. 1), unscrew and remove bypass valve 5 complete with cap.

Unscrew screws 9 securing cover 8 of outlet hole, remove cover and seal 7 of outlet hole.

It is not necessary to perform the last two operations.

To disassemble the diaphragm of the amplifier reducer (Fig. 4-15), it is necessary to unlock the nut 3 of the diaphragm of the reducer and unscrew it.

Remove washer 2, diaphragm 1, washer 6 and gasket 5 from seat 4 of the diaphragm. This unit should not be disassembled unless necessary.

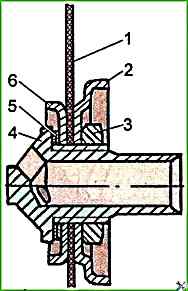

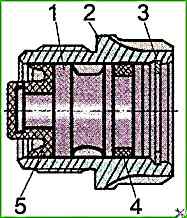

To disassemble the follower piston of the amplifier gearbox (Fig. 4-16), remove the sealing ring 3 from the follower piston housing (see Fig. 1).

Remove the follower piston 1, assembled with the cuff and sealing ring, from housing 2 (Fig. 4-16).

Remove the sealing ring 4 and the cuff 5 from piston 1.

Remove the thrust ring 3 from housing 2 of the follower piston

To disassemble the front housing of the amplifier and the pneumatic piston, remove from the front housing, the sealing ring 13 (Fig. 1) of the reducer diaphragm seat, the pneumatic piston 20 of the amplifier in assembly.

Remove the cuff 23 and guide rings 27 from the pneumatic piston 20.

Secure the front housing 26 in a vice, pointing the air supply cover 1 upwards

Unscrew the cover fastening bolts (4 pcs.), remove the cover and take out the amplifier reducer valve 14, removing the adjusting and sealing aluminum gaskets 16 from both sides of the seat of this valve.

Power steering reducer valve (Fig. 4-17) - non-separable design; if necessary, replace as a whole.

Wash the clutch booster parts and units in MS-6, MS-8 TU 6-15-978-76 solution, blow them with compressed air.

Carry out defect detection of parts

Assembly and adjustment of the pneumatic-hydraulic booster

Assembly of the PGU is carried out in the reverse order of disassembly.

Lubricate the piston rod rubber seals and the "D" surface (see Fig. 1) with NG-213 TU 38.101.129-75 liquid. Press the seal 29 into the rear housing 1 using a mandrel (Fig. 4-18).

Install the seal 2, having first assembled it with the sealing rings 1 and 3 (Fig. 4-14), install the washer 28 and the retaining ring 21

To assemble the clutch release piston (see Fig. 1), lubricate all rubber parts and surfaces "A" and "E" with NG-213 TU 38.101.129-75 liquid before assembly.

Install the seal 33, spacer sleeve 32, spring 31, and spacer sleeve 30 on the clutch release piston rod 34.

Insert the assembled unit into the cylinder of housing 1 and install the retaining ring 35.

Install the seal 7 of the outlet, cover 8 and tighten the screws 9 securing the cover. Install and tighten the bypass valve 5 together with the cap 6.

To assemble the follower piston of the amplifier reducer, before assembly, lubricate all rubber parts and the surface "B" with liquid NG-213 TU 38.101.129-75.

Then install the sealing ring 4 and the cuff 5 on the piston 1 (see Fig. 4-16);

install the follower piston 1 as an assembly into the housing 2; install thrust ring 3 in body 2 of follower piston and put sealing ring 3 on body of follower piston (see Fig. 1).

To assemble diaphragm of reducer, install two gaskets 5, washer 6, two diaphragms 1 and washer 2 on seat 4 (Fig. 4-15), tighten nut 3 with torque of 20-25 Nm and lock by punching at one point.

To assemble front body of amplifier and pneumatic piston, it is necessary to install cuff 23 and guide rings 27 on pneumatic piston 20 (see Fig. 1).

Then install pneumatic piston 20 assembly in front body of amplifier.

Before its installation, fill cavity "B" and lubricate surface "G" with thin layer of grease 158 TU 38.101.320-77.

Install a new sealing ring 13 of the reducer diaphragm seat into the front housing of the amplifier.

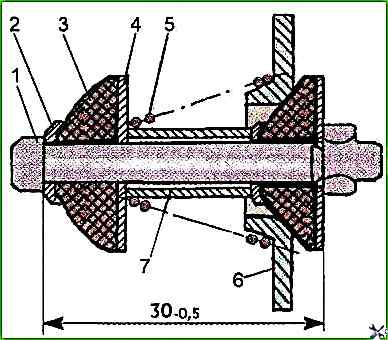

After reassembling the assemblies of the pneumohydraulic amplifier, install the rear housing 1 of the amplifier in a vice with the connector facing up.

Tighten the housing of the follower piston of the reducer in assembly into the rear housing of the amplifier using a special key.

Place the diaphragm of the amplifier reducer 10 in assembly with the seat on the rear housing of the amplifier, the surface of which "G" is lubricated with a thin layer of grease 158 TU-38.101.320-77, and align its holes with the holes for the mounting bolts in the rear housing of the amplifier.

Insert extension rods (diameter 6 mm, length 100 mm) into these holes. Install the gearbox diaphragm spring 11 and the pneumatic piston spring 22.

Install the front housing of the amplifier 26 as an assembly on the rear housing 1, aligning the holes for the mounting bolts with the guide rods.

Press on the front housing and compress the springs until the gap between the housings is eliminated, and the diaphragm seat should enter the hole in the front housing where the sealing ring 13 is located.

It is unacceptable for the seat to rest rigidly against the housing (especially with a noticeable increase in the compression force)

Without releasing the front housing, remove one guide rod, insert bolt 19 with a spring washer and tighten it completely, but do not tighten it and, alternately removing the guide rods, insert and tighten bolts 12, 19 (second) and 25 with spring washers.

After this, tighten the bolts evenly to the end.

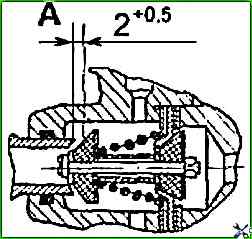

Install the valve of the amplifier reducer 14 in assembly in the front amplifier body, adjusting the gap "A" (Fig. 4-19).

Gap "A" (seat travel before contact with the valve) should be 2+0.5 mm.

It should be adjusted using shims 16 (see Fig. 1), of which at least one should be installed on each side of the seat.

The gap size is determined as follows:

- measure the movement of the diaphragm seat, which is the difference in the distances from the end of the seat to the end of the front housing in the initial position and after the seat has completely moved when pressure is created in the hydraulic system of the PGU to overcome the resistance of the compressed spring of the reducer 11;

- - install valve 14 with one shim under the seat and press it tightly into the socket using a tubular sleeve with a mounting flange;

- - measure the displacement of the valve stem 1 (Fig. 4-17), which is the difference in the distances from the end of the valve stem to the end of the tubular pressure sleeve in the initial position and after the valve stem has fully moved when creating pressure in the hydraulic system of the PGU.

The pressure in the hydraulic system can be created using compressed air of 0.5-0.6 MPa, supplied through the hole for connecting the hydraulic hose, after tightening the bypass valve.

The difference between the displacement of the diaphragm seat and the displacement of the valve stem will be the gap between the diaphragm seat and the outlet valve.

If this value is less than the specified one, then adjusting linings (the thickness of one lining is 0.5 mm) are placed under the valve seat until the required value is obtained gap.

It is best to move the diaphragm seat and valve stem using the depth gauge ШГ-160 GOST 162-73.

Install the air supply cover 17 (Fig. 1) on the front housing of the amplifier and tighten the bolts that secure it.

There should be a uniform gap of 0.5-1 mm around the entire perimeter between the front housing and the cover to ensure that the cover is pressed firmly against the valve seat and that it is tight.

If this requirement is not met, an air leak will occur. After assembly, it is necessary to check the tightness of the air and hydraulic parts of the CCGT.

To check the tightness of the air part of the CCGT, it is necessary to connect a one-liter tank equipped with a pressure gauge and an inlet shut-off valve to the air supply cover 17.

Compressed air at a pressure of 0.5-0.7 MPa is supplied to the tank inlet.

First, the inlet part is checked, which is the volume under the air supply cover, the seal of the end of the cover with the valve seat 14 and the seal of the rear cone (inlet) valve and the valve seat.

To do this, the inlet valve of the liter tank is closed and the pressure drop is measured.

The tightness is considered satisfactory if the pressure in the tank drops by no more than 0.05 MPa in 30 seconds.

Then the working the air part, which additionally includes a seal of the front cone (outlet) valve and the reducer diaphragm seat, a seal of the pneumatic piston cuff between the piston itself and the wall of the front housing cylinder, a seal of the diaphragm between the front and rear housings, as well as the tightness of the front housing and the pneumatic piston themselves.

To do this, a pressure of 0.5-0.7 MPa is created in the pneumatic system of the PGU, the inlet valve of the liter tank is closed and the pressure drop is measured.

The tightness is considered satisfactory if the pressure in the tank drops by no more than 0.05 MPa in 30 seconds.

To check the tightness of the hydraulic part, it is necessary to install a pressure gauge between the PGU and the main cylinder.

Then the system is bled to remove air from it. The hose is disconnected from the compressed air supply cover.

In the hydraulic a pressure of 6.5-7.0 MPa is created in the system.

The main cylinder is locked and there are no leaks through it.

The tightness is considered satisfactory if the pressure in the pipeline drops by no more than 0.5 MPa in 30 seconds.