Signs of replacing or repairing the clutch master cylinder is the clutch not disengaging (the pedal falls through).

The clutch can only be engaged briefly by sharply pressing the pedal or pressing the clutch twice.

These symptoms are also characteristic of a defective clutch slave cylinder.

Before removing a particular cylinder, you need to visually verify the tightness of the cylinder.

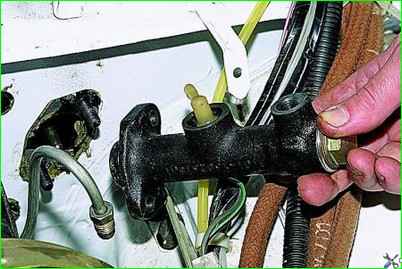

After loosening the hose clamp, remove the hose from the plastic fitting of the master cylinder.

Drain the brake fluid from the clutch hydraulic reservoir into a substitute container or close the hose hole with a plug.

Use a 13mm wrench to unscrew the tube fitting and remove the tube from the cylinder.

Using a 13mm wrench, unscrew the upper nut securing the clutch master cylinder to the front panel.

Unscrew the bottom nut using a 13mm socket with a long extension.

Remove the master cylinder from the studs

Install the master cylinder in reverse order.

Bleed the hydraulic drive (see Bleeding the hydraulic clutch).

If it is necessary to replace the plastic fitting or its seal, pry it up with a screwdriver and remove the locking spring washer

Remove the plastic fitting and the rubber o-ring.

Install the fitting in reverse order.

Clutch master cylinder repair

Remove the clutch master cylinder from the car.

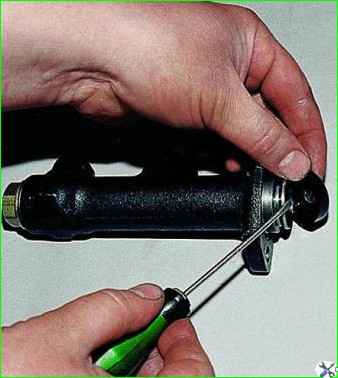

Using a screwdriver, remove the protective cap from the end of the cylinder.

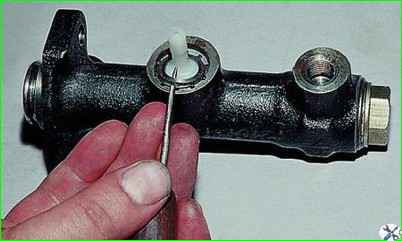

Pry with an awl and remove the lock washer

Remove the fitting with the sealing gasket.

Holding the cylinder in a vice, use a 22mm wrench to unscrew the plug.

Use a puller or pry it with a thin screwdriver to remove the retaining ring

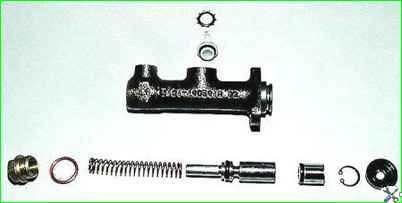

Remove the parts from the cylinder body

We carefully examine the details.

The cylinder bore and the outer surface of the pistons must not have marks or other damage.

The internal diameter of a working master cylinder should be 19.05 +0.025 mm.

If the return spring is deformed or has noticeably decreased elasticity, it should be replaced.

Be sure to replace the rubber O-rings.

Damaged protective We also replace the cap.

Do not expose parts to mineral oil, gasoline, kerosene or diesel fuel, as these substances will cause rubber seals to swell.

The fitting lock washer must not be reused.

Having thoroughly washed the parts with brake fluid, we assemble the cylinder in the reverse order of disassembly.