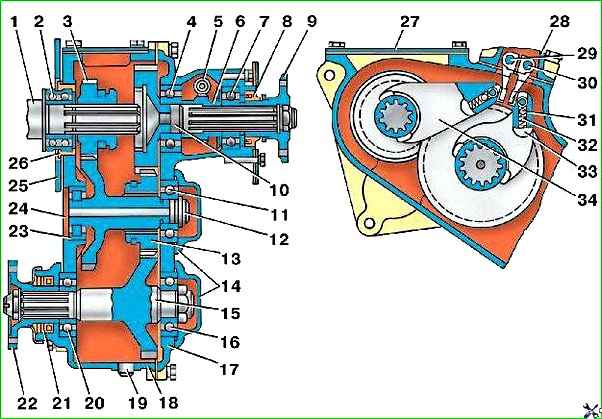

The transfer case is two-stage, mechanical, has an additional reduction gear (Fig. 1)

Some vehicles can be equipped with a modernized “small-module” transfer case, in which the gear teeth of the front and rear axles, as well as the ring gears of the rear and front axle drive shafts, are made with a 2.5 mm module (instead of 3.5).< /p>

At the same time, the low gear ratio decreased and became 1.47 (instead of 1.94).

The transfer cases are interchangeable and look no different.

The modified parts differ from similar parts with a 3.5 mm tooth module in the number of teeth.

Transfer case maintenance

During operation, check the oil level and replace it within the time limits specified in the lubrication table.

Check all fastenings periodically.

If a leak is detected, find out the cause and replace the faulty parts (gaskets, cuffs, plugs, etc.).

During the operation of vehicles, it is possible to reduce the oil level in the gearbox to 8 mm relative to the lower edge of the filler hole and simultaneously increase it in the transfer case.

At the same time, it is not necessary to equalize the oil levels in the gearbox and transfer case, since the total volume of oil ensures the normal operation of both units.

When changing the oil in the transfer case housing or topping it up, it is necessary to simultaneously bring the oil level in the gearbox to the lower edge of the filler hole.

On vehicles of the UAZ-31512 family, lubricate the shift lever axle through a grease nipple. Access to it is from below.

On vehicles of the UAZ-3741 family, when disassembling the control mechanism, lubricate the shafts and lower support, and also adjust the front linkages of the mechanism.

The transfer case has no adjustments.