For grinding the valves, it is most convenient to use a special mechanical device (reversible drill)

To grind the valves with a drill, you need to select a piece of rubber hose that holds the valve tightly

Insert a drill of a suitable diameter into the drill.

Put a piece of hose on the drill.

In addition, ready-made manual valve holders are available for sale.

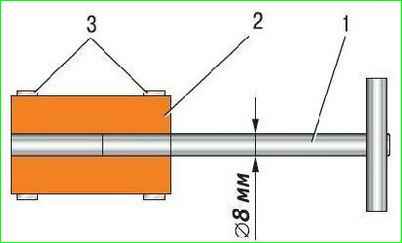

If there are no ready-made devices, you can use a device made according to the drawing shown in Fig. 1.

You will also need: lapping paste, kerosene, a weak spring that goes through the valve seat hole along the outer diameter.

Clean the valve from carbon deposits.

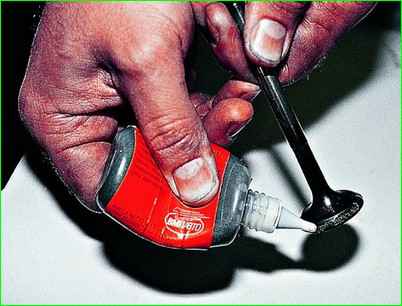

Apply a thin continuous layer of lapping paste to the valve chamfer.

Put a pre-selected spring.

Insert the valve into the guide sleeve from the combustion chamber side, lubricating the valve stem with a layer of graphite grease.

Graphite grease will protect the guide sleeve from getting abrasive from the lapping paste into its hole and will facilitate the rotation of the valve during lapping.

Put the valve grinding device on the valve stem (or, with some tension, a rubber tube for connecting the valve to a reversible drill)

Lap the valve by rotating it alternately in both directions by half a turn and periodically pressing it against the seat, then weakening the pressing force.

This is what the valve looks like when pressed against the seat

Lap the valve until a matte-gray continuous single-color belt at least 1.5 mm wide appears on its chamfer, while a matte-gray belt at least 1.5 mm wide should also appear on the valve seat after grinding.

After grinding, carefully wipe the valve and seat with a clean cloth and rinse to remove any remaining lapping paste

Check the tightness of the valve by installing it in the catch with springs and crackers.

Then lay the head on its side and pour kerosene into the channel that is closed by the valve.

If kerosene does not leak into the combustion chamber within three minutes, the valve is sealed.