The cars use a distributed fuel injection system

Distributed injection is called because the fuel is injected into each cylinder by a separate injector.

The fuel injection system allows you to reduce the toxicity of exhaust gases while improving the driving performance and fuel economy of the car.

Diagnostics of the injection system using diagnostic codes is described in the article - "On-board diagnostics and fault codes"

When working with the injection system, be sure to follow these rules:

- 1. Before removing any components of the injection control system, disconnect the wire from the "-" terminal of the battery.

Disconnect the battery only with the ignition off.

- 2. Do not start the engine if the battery cable lugs are not tightened properly.

- 3. Never disconnect the battery from the vehicle electrical system while the engine is running.

- 4. When charging the battery, disconnect it from the vehicle electrical system.

- 5. Do not allow the electronic control unit (ECU) to heat up above 65°C when operating and above 80°C when not operating (e.g. in a drying chamber).

The ECU must be removed from the vehicle if this temperature is exceeded.

- 6. Do not disconnect or connect the wiring harness connectors to the ECU with the ignition on.

- 7. Before performing arc welding on the vehicle, disconnect the wires from the battery and the wire connectors from the ECU.

- 8. All voltage measurements should be performed using a digital voltmeter with an internal resistance of at least 10 megohms.

- 9. The electronic components used in the injection system are designed for very low voltage, so they can be easily damaged by electrostatic discharge.

To prevent damage to the ECU by electrostatic discharge:

- – do not touch the ECU connectors or electronic components on its boards with your hands;

- – when working with the programmable read-only memory (EPROM) of the control unit, do not touch the pins of the microcircuit.

The vast majority of fuel injection system malfunctions are caused by failure of the following sensors:

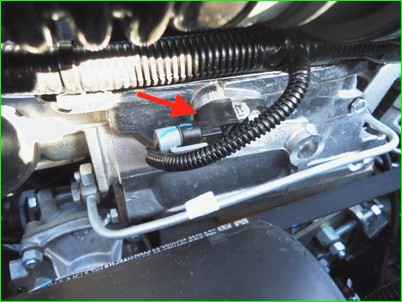

– crankshaft position sensor (synchronization) – complete failure of the injection system, the engine does not start;

- camshaft position sensor – engine starting becomes difficult, especially the first start.

Increased fuel consumption, poor throttle response, malfunction lamp in instrument cluster is on

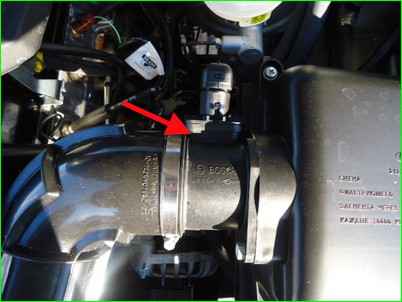

– mass air flow sensor – increased fuel consumption, significant deterioration in dynamics, problems with starting the engine;

– throttle position sensor – loss of power, jerks and dips during acceleration, unstable operation in idle mode;

– coolant temperature sensor – difficulty starting in cold weather: you have to warm up the engine, maintaining the speed with the accelerator pedal, when overheating, the power is significantly reduced, detonation appears;

– knock sensor – the engine is very sensitive to the quality of gasoline, increased tendency to detonation;

– oxygen sensor ("lambda probe") – increased fuel consumption, decreased engine power, unstable idling.

Possible damage to the catalytic converter of exhaust gases

– speed sensor – inability of the system to self-learn to adjust to the driving style of a specific driver.

Possible deterioration of the dynamic qualities of the car in modes using maximum power (intensive acceleration).