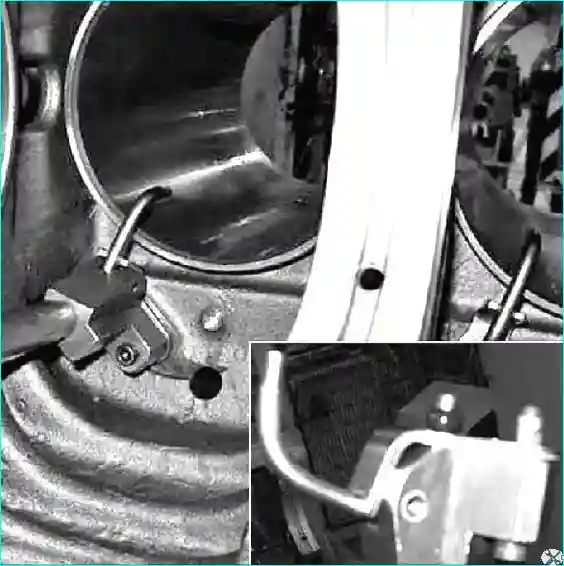

Assemble the piston cooling nozzle (650.1004118) with the gasket (650.1004121).

Install the nozzle in place, tighten the bolts (310107) and tighten Mkr = 20 ± 4 Nm (see Fig. 1)

Install the upper crankshaft bearing shells, aligning the lubrication holes and lubricating the working surface with oil.

Fig. 1. Installing the piston cooling nozzle

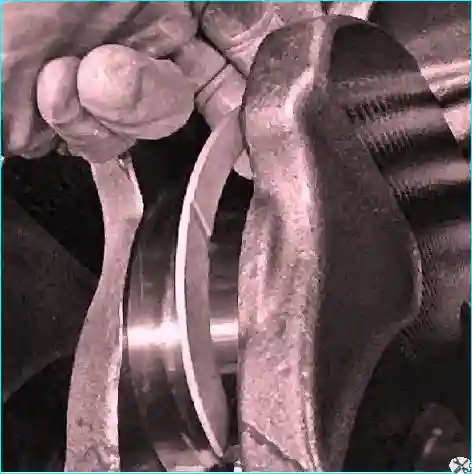

Install the upper thrust half rings with the slot towards the crankshaft cheek (see Fig. 2).

Install the crankshaft, having previously lubricated the connecting rod and main journals with oil.

Fig. 2. Installing the YMZ-650 thrust half rings

Install the crankshaft bearing shells into the lower main bearing caps and lubricate the working surface with oil.

Install the crankshaft main bearing caps with the shells, observing the numbering.

Install the middle cap together with the half rings with the convex part towards the crankshaft cheek (see Fig. 2).

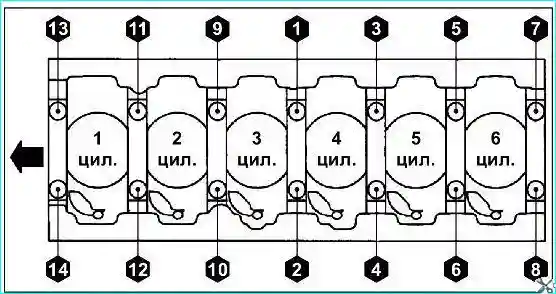

Fig. 3. The order of tightening the bolts of the main bearing caps of the crankshaft YaMZ-650

Fit the bolts and tighten them to the recommended torque in the order shown in Fig. 3:

- - ensure the first tightening by 80 ± 8 Nm;

- - ensure the second tightening by 180˚ ± 6˚.

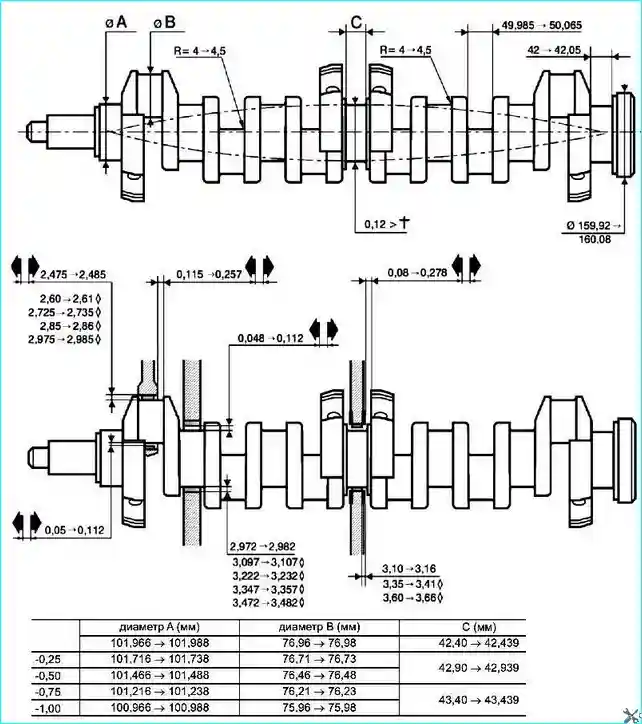

Fig. 4. Dimensions and tolerances of the YMZ-650 crankshaft

Check rotation.

Check the gap between the thrust half ring and the crankshaft cheek (see Fig. 4).

Adjust, if necessary, using half rings of different thicknesses.

Be sure to replace those bolts whose length under the head exceeds 156 mm.

When reusing and subsequently using bolts, lubricate the threads with Loctite 518 sealant.

New bolts do not require lubrication, since they are already lubricated.

Crankshaft tightening torques

Crankshaft main bearing cap fastening bolts:

- - preliminary tightening torque: 80 ± 8 Nm

- - final tightening torque: 180 ± 6 Nm

Flywheel mounting bolts with manual transmission. Bolts are used only 2 times. Installing the bolts for the third time is not allowed.

- - preliminary tightening torque: 60 ± 6 Nm

- - final tightening torque: 120 ± 6 Nm

Connecting rod cap mounting bolts:

- - preliminary tightening torque: 80 ± 8 Nm

- - final tightening torque: 90 ± 6 Nm

Damper mounting bolts on the hub:

- - preliminary tightening torque: 50 ± 5 Nm

- - final tightening torque: 120 ± 12 Nm

Pulley mounting bolts damper 67 ± 7 Nm