Replacing the generator drive belt of the Lada Vesta with a VAZ-21129 engine

We remove the belt for its replacement or for work related to the replacement of drive units, as well as when replacing the timing belt

We install the car on a lift or in an inspection pit. Disconnect the negative battery terminal.

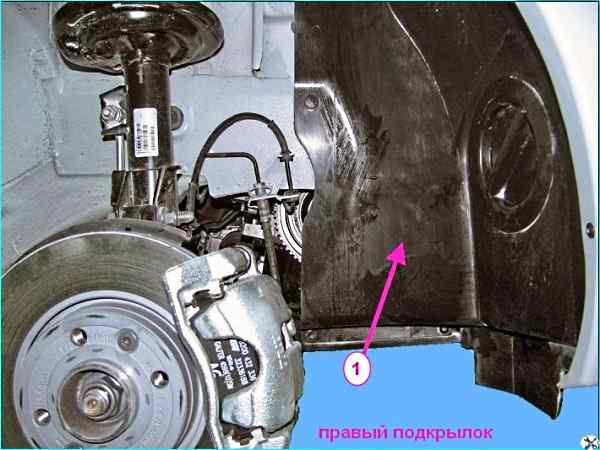

Remove the right wheel.

Remove the mudguard 1 (Figure 1) of the right front fender.

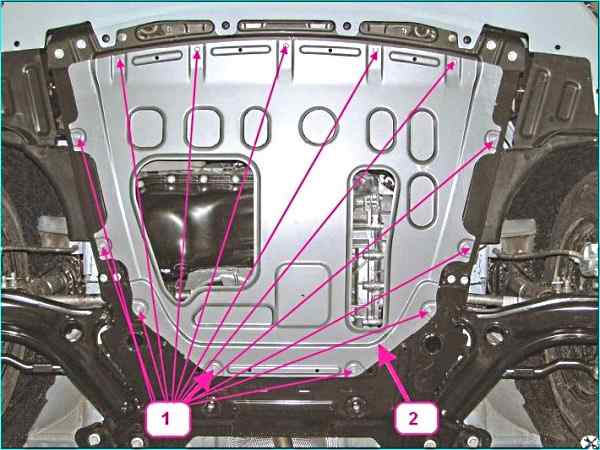

Using a 10 mm socket, unscrew the thirteen bolts 1 (Figure 2) and remove the engine guard.

If a manual gearbox is installed, then:

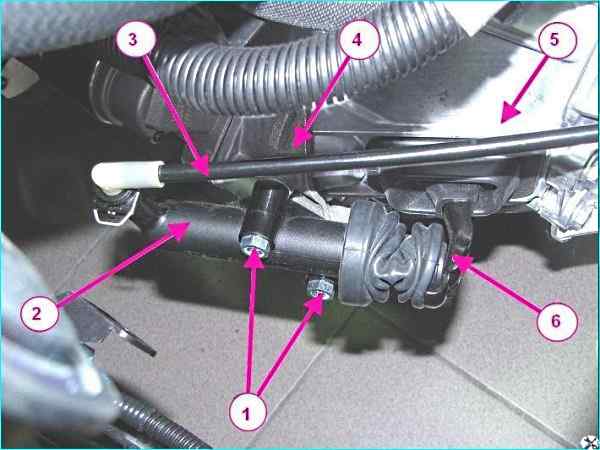

- with a 13 mm head, unscrew the two bolts 1 (Figure 3), and remove the clutch slave cylinder and hang it on a hook without disconnecting the tubes 3 of the hydraulic drive.

If the car does not have air conditioning, then:

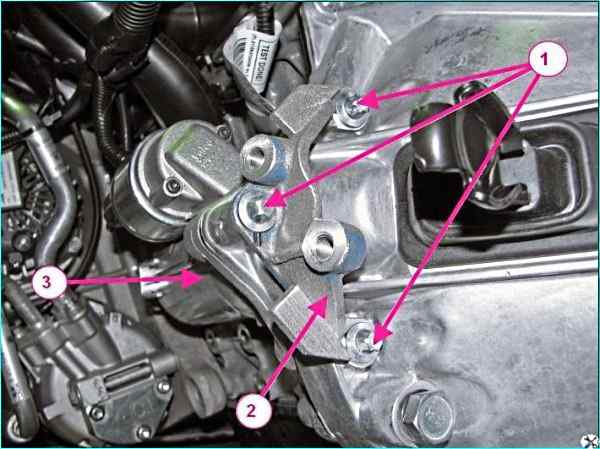

- using the Torx E10 head, unscrew the three bolts 1 (Figure 4), and remove the bracket 2 for fastening the clutch cylinder (for cars with a manual transmission), remove the starter 3 without disconnecting the terminal and connector of the wiring harnesses suitable for the starter, and hang it on the wire.

Install the device for locking the flywheel in the holes for the starter mounting bolts on the gearbox.

If the car is equipped with an air conditioner (with a tension roller for the drive belt of the units), then:

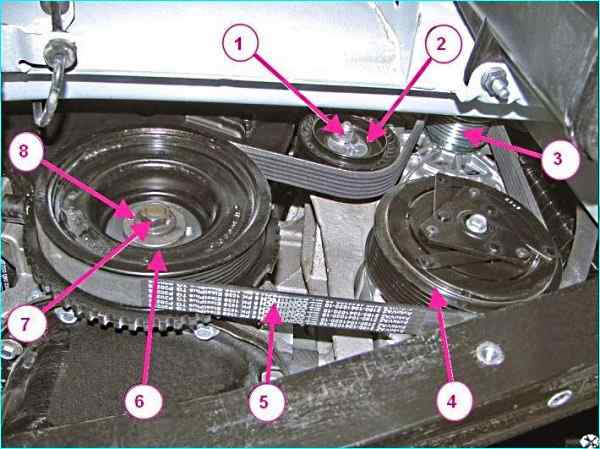

- remove the tension roller plug, loosen the nut 1, figure 5, fastenings and move the tension roller 2 counterclockwise to the upper position (use a 13 head and a TorxT55 nozzle).

If the car does not have air conditioning, then:

- unscrew the bolt 7 of the damper mount, carefully remove the washer 8 and the damper 6 of the crankshaft (use a 17 head).

Next, remove the belt.

Installation

For cars without air conditioning:

Install the damper, washer on the crankshaft and secure with a bolt. Tightening torque of the damper mounting bolt 95-115 Nm (9.5-11.5 kgf.m) (replaceable head 17, ratchet wrench, torque wrench).

Install mounting device 67.7834-9703 on the damper pulley (device 67.7834-9703 for installing the elastic auxiliary drive belt).

Install the belt on the generator pulley and put it on the damper using device 67.7834-9703.

Turning the damper by the head of the mounting bolt in the direction of ¾ of a turn clockwise, put the belt on the damper grooves (ring wrench 17).

Stop rotating the damper after releasing the device from the belt 67.7834-9703 and remove the device from the damper pulley.

Install the starter 3, Fig. 4, and the bracket 2 for fastening the clutch hydraulic cylinder (for vehicles with a manual transmission) and secure with three bolts 1.

The tightening torque of the bolts is 18…24 Nm (1.8…2.4 kgf.m) (replaceable Torx head E10, extension, ratchet wrench, torque wrench).

For vehicles with a manual transmission additionally:

Install the cylinder 2, Fig. 3, of the clutch hydraulic drive and secure with two bolts 1. The tightening torque of the bolts is 18-24 Nm (1.8-2.4 kgf.m) (replaceable head 13, ratchet wrench, torque wrench).

For vehicles without air conditioner

Install mudguard 2, figure 2, of the engine and tighten thirteen bolts 1 (replaceable head 10, ratchet and extension).

For cars with air conditioner (with the tension roller of the accessory drive belt)

Install the belt 5, Figure 5, of the accessory drive in the following sequence:

- - damper 6 of the crankshaft;

- - pulley 4 of the air conditioner compressor;

- - pulley 3 of the generator;

- - tension roller 2.

Move tension roller 2 to the lower position clockwise and tighten nut 1 of the tension roller fastening.

Tightening torque of the nut 30-36 Nm (3.0-3.6 kgf.m) (used: - replaceable head 13, Torx T55 nozzle, ratchet, torque wrench).

Install the plug tension roller.

Install the right front fender shield

Install the right front wheel and connect the negative battery terminal.