When performing work related to depressurization of the air conditioning system, it is necessary to completely unload the refrigerant and then load the system

Before bleeding the system, it is necessary to observe safety regulations and wear glasses

Bleed the refrigerant from the air conditioning system outdoors or in a well-ventilated area.

At atmospheric pressure, the refrigerant turns into a gaseous state.

Bleed the refrigerant from the system in a very thin stream.

When bleeding the refrigerant, some of the oil mixed with it may splash out.

To protect the underhood space from contamination, place a wiping cloth around the service valve.

Prepare the car for work, open the hood

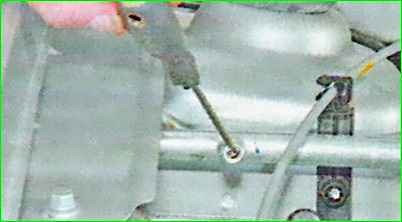

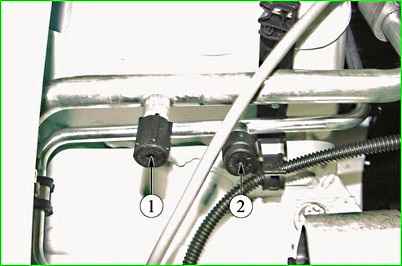

Unscrew the threaded cap of any of the two service valves

Press a thin screwdriver with a long tip on the tip of the valve spool and bleed the refrigerant from the system

Before pumping in the refrigerant, you need to vacuum the air conditioning system

To completely remove air and water vapor from the system, you need to use a two-stage vacuum pump

Refrigerant must be filled with the engine off through the high pressure circuit

The mass of the refrigerant (R134a) filled into the system is 475 ± 35 g.

If the system is not fully loaded with refrigerant, top it up with the engine running and the air conditioning system on through the low pressure circuit with gaseous refrigerant.

Checking the air conditioning system components

Check the air conditioning system components for mechanical damage, replace damaged components.

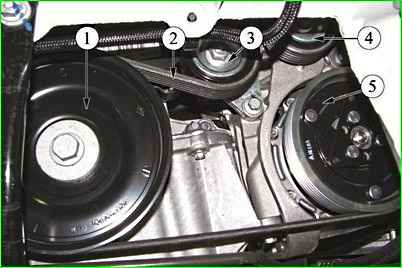

Check the condition of the auxiliary equipment drive belt

Check the condition of belt 2, accessory drive. The presence of cracks, fraying and delamination of the belt is not allowed.

If it is necessary to replace the auxiliary drive belt:

- - turn the automatic tension roller 3, auxiliary drive belt clockwise;

- - lock the tension roller 3 with a hex key;

- - remove the auxiliary drive belt 2;

- - remove the tension roller 3 and the idler roller 4;

- - install new tension and idler rollers;

- - turn the automatic tension roller 3;

- - lock the tension roller 3 with a hex key;

- - install a new auxiliary drive belt 2;

- - unlock the roller 3 tensioner.

The removed accessory drive belt must be replaced.

When replacing the accessory drive belt, be sure to replace the tensioner and idler rollers.

Checking the engagement of the compressor electromagnetic clutch

Start the engine and warm it up to operating temperature, turn on the heater fan motor and the air conditioner switch.

If necessary, eliminate the malfunction in accordance with TI3100.25100.12043 "Diagnostics of the air conditioning system of the LADA LARGUS car".

Checking the amount and condition of the refrigerant in the air conditioning system

Check the amount and condition of the refrigerant in the air conditioning system:

- - connect the service hoses to the fittings on the air conditioning system pipes and open the valves on the hose tips;

- - start and warm up the engine to operating temperature;

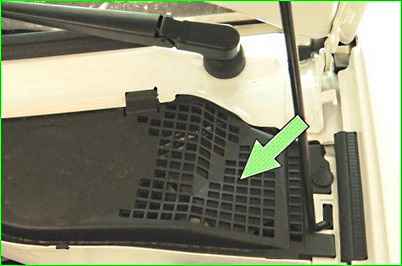

- - set the air recirculation mode to the outside air intake position;

- - turn on the heater fan motor and set the maximum rotation speed;

- - open the central and side ventilation nozzles on the panel and set them to the neutral position;

- - set the air conditioner switch to the "on" position and turn the temperature regulator to the "MIN" position;

- - close all windows and doors of the car;

- - ensure that the engine cooling system fan is constantly running;

- - set the engine crankshaft speed to 2000 rpm;

- - measure the ambient temperature air (T3), after stabilization of values;

- - wait 5 minutes and measure the air temperature from the left side ventilation nozzle (T1) and the right side ventilation nozzle (T2);

- - after the values have stabilized, determine the temperature difference between T3 and the largest of the values T1 or T2;

- - determine the difference in values between T1 and T2.

If the temperature difference between T1 and T2 is greater than 2°C or the temperature difference between T3 and the largest of the values T1 or T2 is less than 5°C, then the system is faulty and it is necessary to diagnose the air conditioning system in accordance with TI 3100.25100.12043 "Diagnostics of the air conditioning system of the LADA LARGUS car".

When replacing elements of the air conditioning system, top up the compressor oil according to the table

The total amount of compressor oil (Sanden SP-10) in the system is 135 ± 10 g.

Operation performed - Amount of oil to be added, ml

Refrigerant discharge - Measure the amount of drained oil and add the same amount

Pipe rupture or major leak - 100

Condenser replacement - Amount of drained oil + 30

Evaporator replacement - Amount of drained oil + 30

Receiver-dryer replacement - Amount of drained oil + 15

Pipe replacement - Amount of drained oil + 10

Removing and installing compressor - Amount of drained oil

Compressor replacement - Oil is not added

Replacing the compressor and one or more elements of the air conditioning system - Oil is not added

Compressor unit replacement - Top up with the specified brand of oil

Complete replacement of the compressor and one or more elements of the air conditioning system - Top up with the specified brand of oil