The crankshaft position sensor is designed to generate signals by which the ECU synchronizes its operation with the engine operating cycle

Therefore, this sensor is often called a synchronization sensor.

The operation of the sensor is based on the principle of induction - when the crankshaft pulley teeth pass the sensor core, AC voltage pulses appear in the sensor circuit.

The frequency of pulses corresponds to the crankshaft rotation speed.

The teeth are located around the circumference of the pulley (every 6°). Two of them are separated from each other at an angular distance of 18°.

This was done to form reference signals in the sensor circuit - unique reference points relative to which the ECU determines the position of the crankshaft - top dead centers in the first/fourth and second/third cylinders.

Engine operation with a faulty crankshaft position sensor is impossible.

The crankshaft position sensor cannot be repaired; in the event of a malfunction, it is replaced as an assembly.

If the sensor fails, the injection system completely fails and the engine does not start.

Removing and installing the crankshaft position sensor

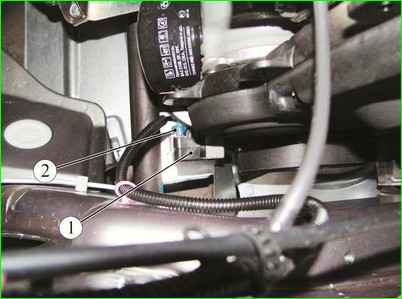

You can remove the crankshaft sensor from above, but for clarity we show the operation from below

Turn off the ignition

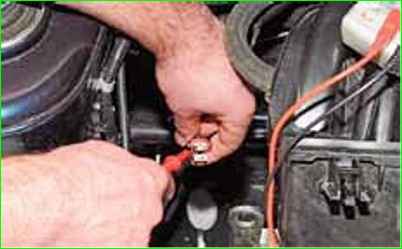

Press the clamp of the wiring harness block and disconnect the block from the sensor connector

To check the serviceability of the sensor circuit, connect the tester probes to one of the two terminals of the wire block and engine ground.

With the ignition on and the crankshaft stationary, the tester should record a voltage of about 2.5 volts

The same voltage should be between the other terminal of the wire block and the engine ground

If there is no voltage, then you need to check the serviceability of the circuits (open and short to ground) between terminal 1 of the sensor wiring harness block and terminal “B1” of the brown block of the controller wiring harness, as well as between terminal “2” of the sensor wiring harness block and terminal “A1” of the controller wiring harness block.

If the voltage values do not match and the circuits are working, the controller is faulty.

To check the sensor, it must be removed.

To do this, use a 10mm head to unscrew the sensor mounting bolt

Remove the sensor from the oil pump cover boss

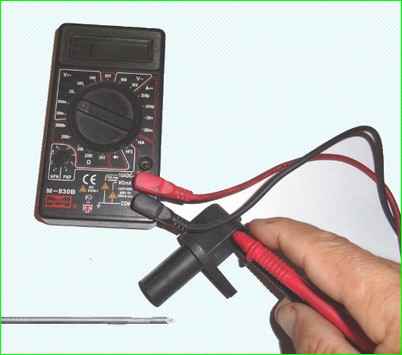

Connect the tester probes to the sensor terminals and measure the resistance of its winding

Resistance should be 650-750 Ohm

Connect the tester to voltage measurement mode (in voltmeter mode with a measurement limit of up to 200 mV) and several times bring a steel rod to the end of the sensor

If the sensor is working properly Depending on the position of the crankshaft, the device should detect voltage surges

Install the crankshaft position sensor in reverse order.

Using a set of feeler gauges, we check the gap between the end of the sensor and the teeth of the crankshaft pulley.

The gap should be 1±0.41 mm; it is specified by the design of the sensor and is not adjustable.

The sensor can be checked more accurately by taking readings from it while it is installed on the engine and the crankshaft pulley is rotating.

For a working sensor, the voltage at the terminals reaches 0.3 V. We replace the faulty sensor.