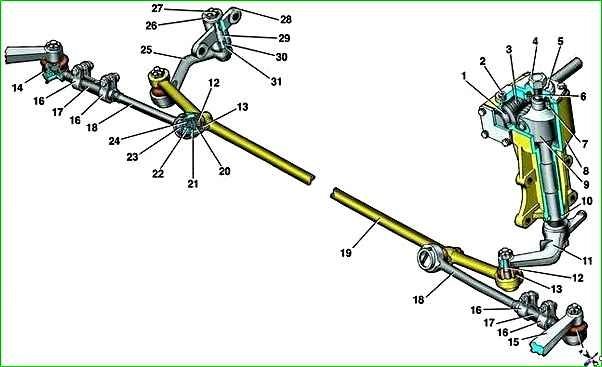

Removal and installation of steering linkage GAZ-3110

Place the vehicle on the parking brake.

Install stands for the rear wheels.

Raise and place the front part of the car on supports.

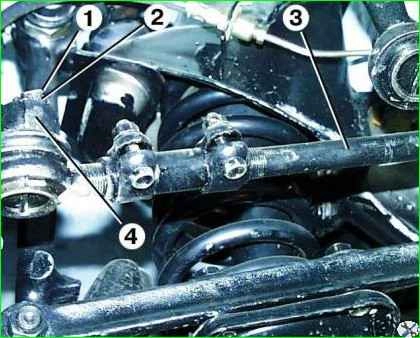

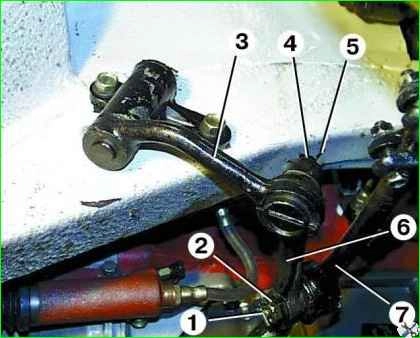

Remove the cotter pin 1, unscrew the nut 2 and press the steering rod ball joint pin 3 out of the swing arm 4.

Remove the cotter pin 1, unscrew the nut 2 and press the steering rod ball joint pin 7 out of the bipod rod 6.

Remove the cotter pin 5, unscrew the nut 4 and press the end of the bipod rod 6 from the ball joint pin of the pendulum arm 3.

In a similar way, press the ball joint pin out of the bipod from the other end of the bipod rod.

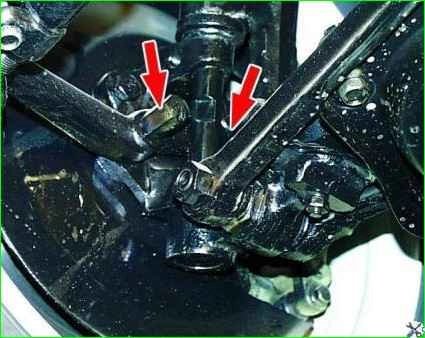

Unscrew the two mounting bolts and remove the steering arm from the steering knuckle

Inspection of the steering linkage

Carefully inspect the details of the steering linkage.

Worn and deformed parts cannot be repaired and must be replaced.

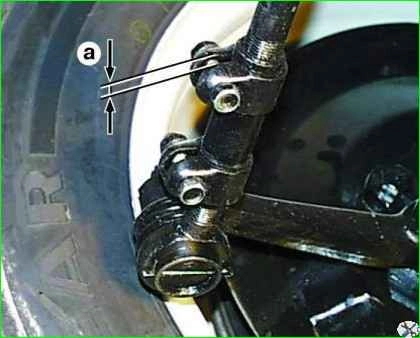

Check the clamps of the adjusting tubes.

If the distance “a” between the ears of the tightened clamps is less than 1 mm, such clamps must be replaced.

Installing the steering linkage

Install the steering linkage in the reverse order of removal.

In this case, the bolts securing the swing arm to the steering knuckle and the ball pin nuts are tightened to a torque of 40–50 Nm (4.0–5.0 kgf m).

To align the slot of the ball pin nut with the hole for the cotter pin, the nut only needs to be tightened no more than one slot.

The nuts for fastening the adjusting tubes of the steering rods are tightened to a torque of 15–18 Nm (1.5–1.8 kgf m).

When installing new side tie rod ends, you must turn the steering wheel to the straight-ahead position.

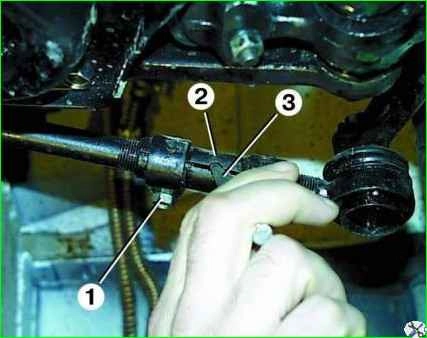

Loosen the tightening bolts 1 of the clamps.

Then, changing the length of the left side rod using the adjusting tube

set the left wheel to the position where the vehicle is moving in a straight line.

To rotate the adjusting tube, insert the bit 3 into its hole.

Adjust the wheel toe by changing the length of the right side rod using the adjusting tube.

The ears of the clamps should lie in the same plane and be directed in one direction.

The clamp bolts are tightened to a torque of 15–18 Nm (1.5–1.8 kgf m), their heads should also be directed in one direction.