Before disconnecting hoses and electrical wires, it is recommended to mark them so as not to mix them up during assembly

The engine is removed from the car upwards

To remove the engine, a hoist or other lifting device with a lifting capacity of at least 300 kg is required.

The car must be installed on a lift, inspection ditch or overpass.

Before removing the engine, it is necessary to prepare a reliable stand on which the engine must stand stably.

Remove the battery.

Remove the hood.

Remove the front engine splash guard.

Drain the engine cooling system.

Drain the oil from the engine crankcase.

Drain the oil from the gearbox.

Remove the cooling system radiator.

Disconnect the high voltage central wire and the low voltage wire from the ignition distributor.

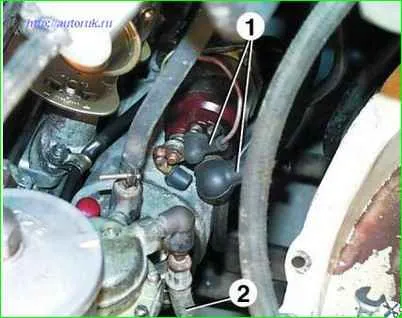

Disconnect the wires from the starter by removing rubber protective caps 1.

Disconnect fuel line 2 from the fuel pump.

Disconnect the wire from the emergency oil pressure sensor installed at the bottom of the oil filter.

Disconnect the oil cooler supply hose from the tap located at the bottom of the block on the left side.

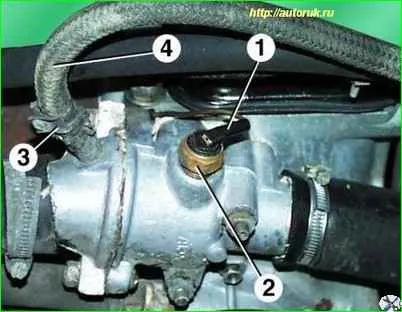

Disconnect wire 1 from coolant temperature indicator sensor 2.

Loosen the tightening of clamp 3 and disconnect hose 4 from the thermostat housing cover.

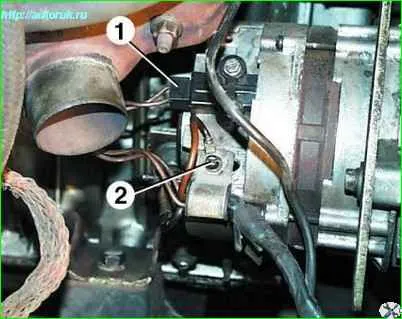

Disconnect the wires from the generator by disconnecting block 1 and unscrewing screw 2.

Remove the air filter.

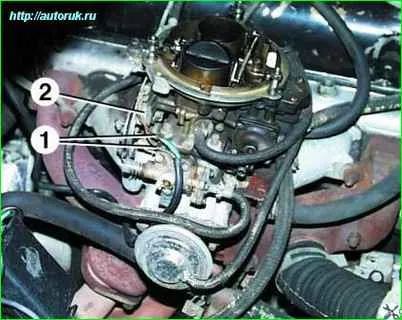

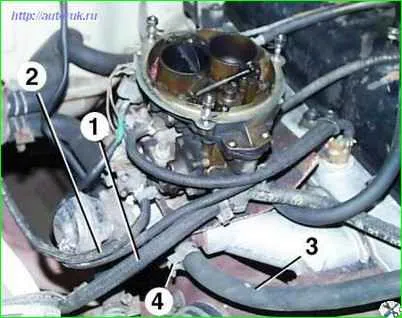

Disconnect wires 1 from microswitch 2 on the carburetor.

Disconnect the choke rod 2 from the carburetor air damper drive lever and, by unscrewing screw 1, remove the rod 2 from the bracket.

Disconnect accelerator drive rod 4 from the throttle valve drive sector, unscrew nut 3 and remove rod 4 from the bracket.

Disconnect fuel drain hose 1 from the carburetor.

Disconnect vacuum hose 2 of the EPHH solenoid valve and the vacuum hose from the vacuum supply tube to the EPHH valve on the other side of the carburetor.

Disconnect vacuum hose 3 of the brake booster from the fitting on the engine intake pipe by loosening clamp 4.

Disconnect the oil supply hose from the oil cooler from the fitting at the bottom of the block on the right side.

Disconnect the wire from the oil pressure indicator sensor on the right side of the block.

Disconnect the heater fluid supply and drain hoses from the heater radiator fittings.

Remove the exhaust system.

Remove the gearbox.

Remove the clutch slave cylinder without disconnecting the hose from it, and leave the cylinder hanging on the hose.

Disconnect the ground wire from the clutch housing.

Unscrew the bolt securing the engine mount bracket to the mount on each side.

Check that all hoses and wires are disconnected from the engine.

Carefully lift out the engine.

Install the engine in reverse order.

When installing the engine on the mounts, make sure that the mounting pins on the mounts fit into the holes on the engine brackets, and the holes for the bolts on the bracket should line up x and pillows.