The propeller shaft has two joints and a sliding spline connection.

The propeller shaft forks are attached to the steering screw and the steering column shaft with wedges.

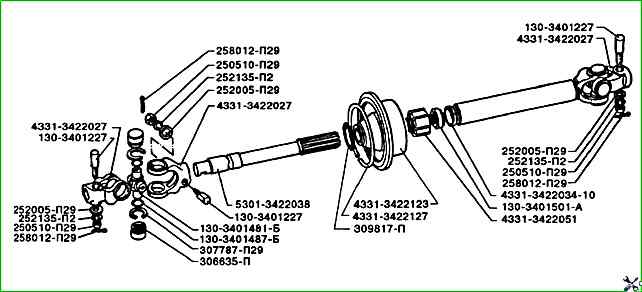

The figure shows the installation locations of the parts and their designations according to the spare parts catalog.

We look at the figure and the table shows the decoding of the part.

Part numbers and names of the ZIL-5301 propeller shaft according to the catalog

Part number - Part name

- 130-3401227 - Wedge for fastening the steering propeller shaft

- 130-3401481-B - Cardan crosspiece

- 130-3401487-B - Sealing ring for the steering propeller shaft crosspiece

- 130-3401501-A - Sealing ring for the steering propeller shaft

- 250510-P29 - Nut

- 252005-П29 - Washer

- 252135-П2 - Spring washer

- 258012-П29 - Cotter pin

- 306635-П - Needle bearing

- 307787-П29 - Thrust ring

- 309817-П - Spring ring

- 4331-3422027 - Cardan shaft fork

- 4331-3422034-10 - Fork with splined sleeve assembly

- 4331-3422051 - Seal nut

- 4331-3422123 - Seal cardan shaft

- 4331-3422127 - Spacer ring

- 5301-3422010 - Steering cardan shaft assembly

- 5301-3422038 - Spline shaft assembly

The cardan shaft has two joints on needle bearings. Rubber rings are used to prevent dirt from getting into the hinge joint.

The splined joint of the cardan shaft is lubricated with the lubricant placed in it, which must be replaced in accordance with the lubrication chart.

The splines are lubricated with a thin layer before assembly, and 18-20 grams of lubricant are placed in the bushing.

A rubber ring is installed to hold the lubricant and protect against dirt

During assembly, 0.8-0.9 grams of lubricant are placed in each needle bearing.

There is no need to replenish the lubricant in the bearing

In case of disassembling the cardan joint, the specified amount of lubricant must be placed in each bearing

When assembling the cardan shaft, it is necessary to ensure that the holes in the forks for the mounting wedges are in parallel planes.

The axes of the fork holes for the bearings must lie in the same plane.

The retaining rings must be securely installed in the bearing grooves.