We remove the rear suspension rods in cases where it is necessary to remove the suspension or repair the rods themselves

Usually the rubber bushings on the rods wear out.

Spare parts stores sell both assembled rods and repair kits.

Of course, if the rods are heavily corroded or heavily deformed, it is better to replace them.

Removing the lower longitudinal rod

We carry out the work on an inspection pit or lift.

We disconnect the lower shock absorber mount from the rear axle beam (see Removing the shock absorber).

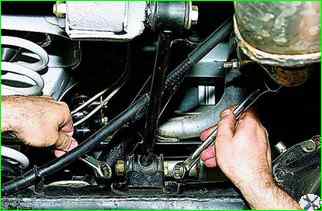

Using a 19 mm open-end wrench, unscrew the nut securing the rod to the rear axle beam, holding the bolt from turning with a wrench of the same size.

Using a punch made of soft metal, knock out the bolt and take it out.

We take the rear end of the rod out of the rear axle bracket eyes.

Using a 19 mm open-end wrench, loosen the nut securing the rod to the body bracket, holding the bolt from turning with a wrench of the same size.

Remove the bolt and remove the rod

To replace the rubber bushings of the rod, clamp it with a little force in a vice.

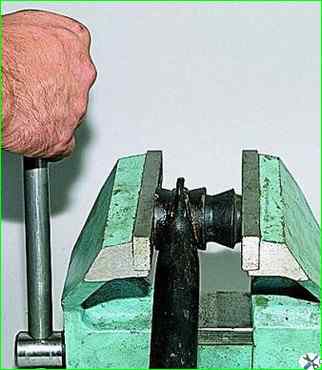

Using a puller, press the bushing into the cup resting on the edges of the eye, and remove the rubber and steel (spacer) bushings.

Lubricate the new rubber bushing with soapy water and press it into the eye in vice.

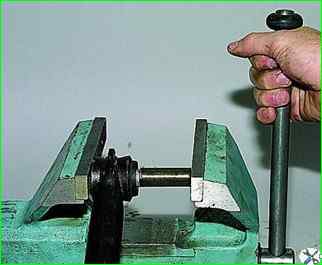

To press in the spacer sleeve, use a conical mandrel or tool head with different outside diameters.

Insert the mandrel into the hole in the rubber bushing lubricated with soapy water and press the spacer bushing in a vice.

To remove the mounting bracket for the front end of the rod, use a 17 mm head to unscrew the four nuts.

Remove the bracket

Install the removed parts in the reverse order.

Removing the upper longitudinal rod

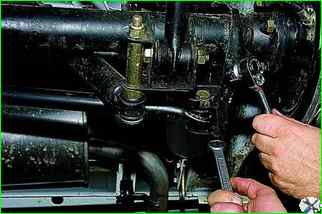

Using a 19 mm open-end wrench, loosen the nut securing the rod to the rear axle beam, holding the bolt from turning with a wrench of the same size.

Using a punch made of soft metal, knock out the bolt

Using a 19 mm open-end wrench, unscrew the nut of the rod mounting bolt to the body side member, holding the bolt from turning with a wrench of the same size

Remove the bolt

Removing the bar

Change the rubber bushings as shown above

Install the bar in the reverse order.

Removing the cross bar

Using a 19 mm open-end wrench, loosen the nut on the bolt securing the crossbar to the body bracket, holding the bolt from turning with a wrench of the same size.

Using a punch made of soft metal, knock out the bolt and take it out.

Using a 19 mm open-end wrench, loosen the nut securing the crossbar to the rear axle beam bracket, holding the bolt from turning the head of the same size.

Using a punch made of soft metal, knock out the bolt and remove the crossbar

See the beginning of the article for replacing the rubber bushings of the crossbar.

Install the bar in the reverse order.

Finally tighten the nuts of the bar mounting bolts in the "car on wheels" position.

Tightening torque of the nuts of the crossbar and longitudinal bar mounting bolts 66.6-82.3 Nm (6.8-8.4 kgf m)