An ignition coil is a transformer, on the iron core of which a secondary winding is wound, and on top of it is a primary winding

The core with windings is installed in a sealed steel case, filled with oil and closed with a high-voltage plastic cover.

Ignition coil maintenance

To prevent possible breakdown of the plastic cover, the ignition coil must be cleaned of dirt, dust and oil, and the high and low voltage wires must be checked for secure fastening.

Withdrawal

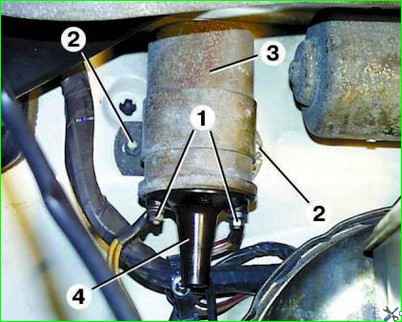

Unscrew nuts 1 and disconnect low-voltage wires from coil terminals 3.

Disconnect high-voltage wire 4 from the ignition coil.

Unscrew nuts 2 and remove coil 3.

Ignition coils B116 and B116–01 are checked on a mod. K–295.

The coil must ensure uninterrupted sparking at the spark gap with a gap of 7 mm at a rotation speed of the ignition distributor shaft of at least 2500 min –1.

Inspect the coil.

If there are chips, cracks, signs of heating or oil leakage on the plastic cover, replace the coils.

Check the resistance of the primary winding of the ignition coil by connecting an ohmmeter between the low voltage terminals.

The ohmmeter should show a resistance of 0.48–0.72 Ohm.

Then check the resistance of the secondary winding by connecting an ohmmeter between the high voltage terminal and the “K” terminal of the coil.

The ohmmeter should show a resistance of 13,200–19,800 Ohms.

If the measured parameters differ from those specified, the coil must be replaced.